Sauce paste bag unwrapping machine

A bag unpacking machine and paste technology, which is applied in the directions of packaging, unsealing of packaged items, and unsealing by removing items, etc., can solve the problems of paste blocking the transmission channel, hindering the development of the hot pot industry, and packaging bags are not easy to collect, etc., so as to reduce man-made Effects of interference, protection of safety, and improvement of hygiene level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following technical solutions in the present invention are clearly and completely described. Obviously, the described embodiments are some embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0021] Embodiment 1 Embodiment 1 is to adopt double transmission belt to carry out feeding

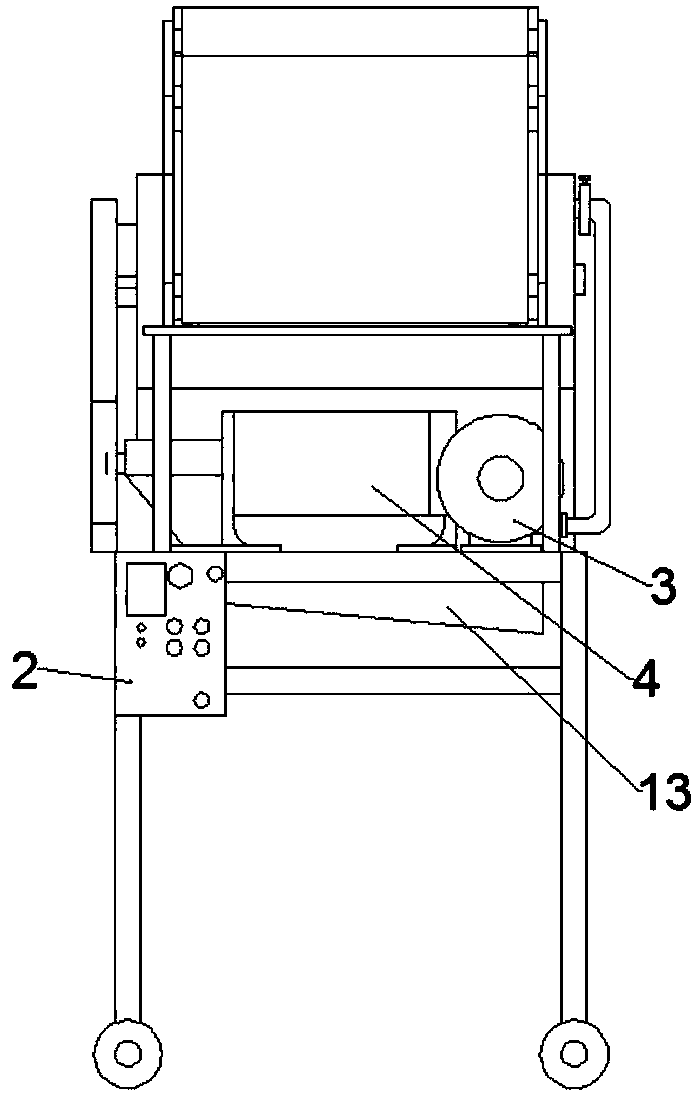

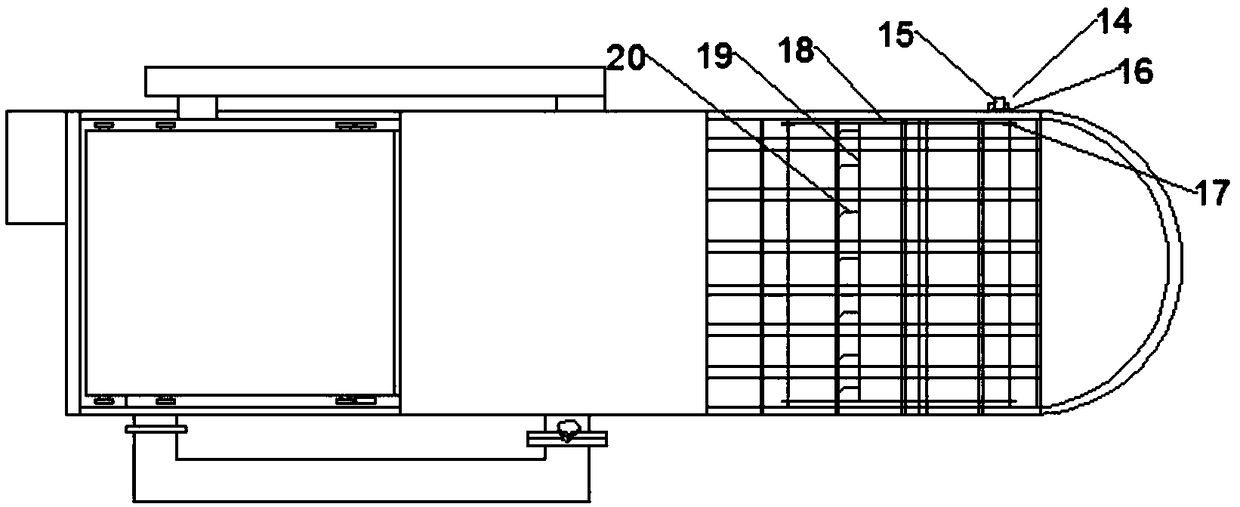

[0022] Such as figure 1 , 2 As shown, a sauce paste unpacking machine includes a frame 1, and universal wheels are installed at the bottom of the frame 1, so that the bag unpacking machine can be moved to any position to realize bag unpacking.

[0023] The upper left side of the frame 1 is equipped with a transmission belt through the transmission belt bracket 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com