Folding and gluing machine pressing device with cleaning assembly

The technology of a box gluing machine and components is applied in the directions of box making operation, rigid/semi-rigid container manufacturing, packaging, etc., which can solve the problems of low cleanliness of the working environment, waste of manual cleaning of the platen, and poor box gluing effect, etc. Achieve the effect of preventing pollution of the working environment, saving glue, saving time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

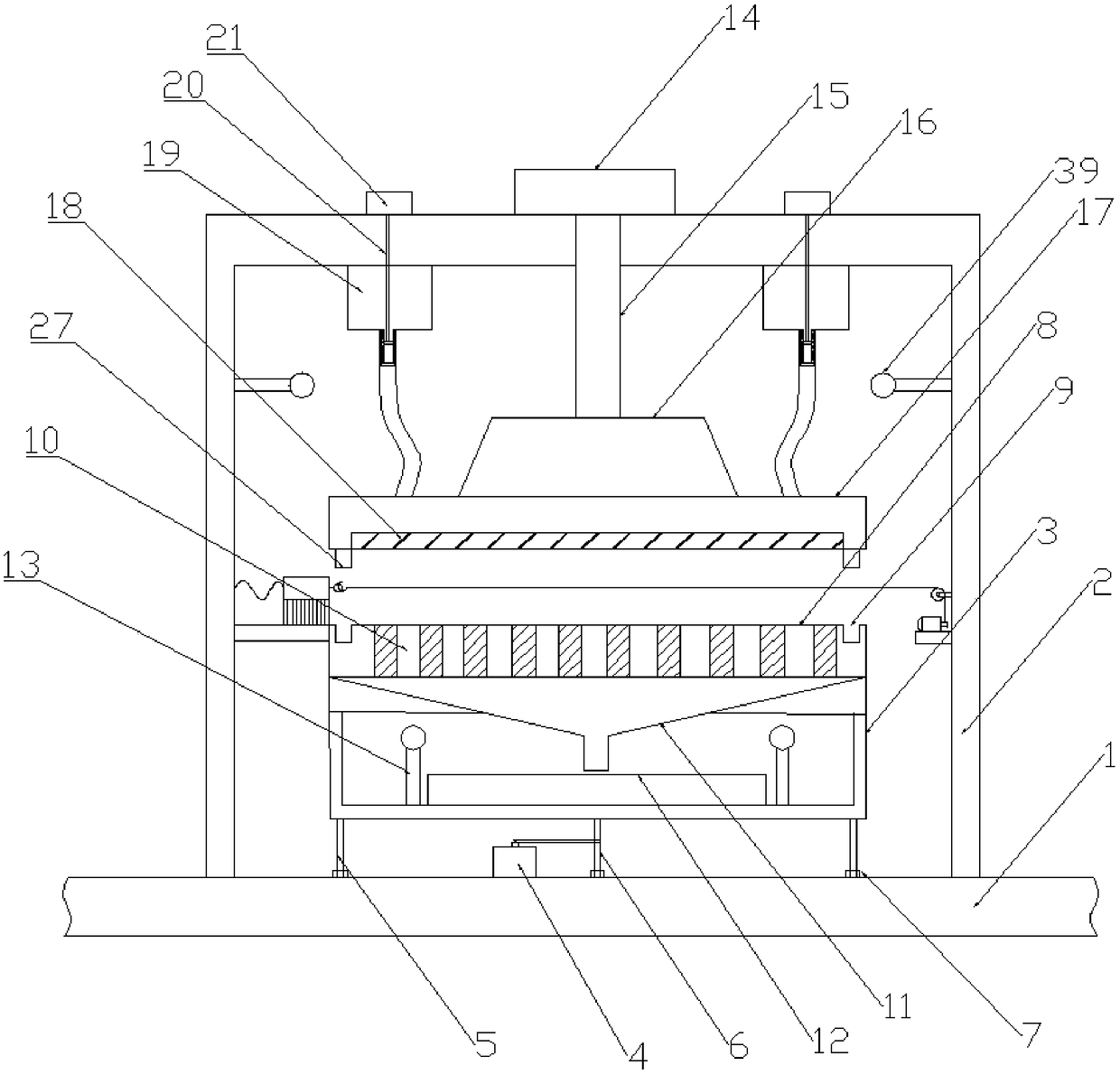

[0030] Such as Figure 1-6 As shown, a box gluer pressing device with a cleaning assembly includes an operating table 1, on which a fixed frame 2 and a first rotating motor 4 are arranged, and first fixed frames are respectively provided on both sides of the fixed frame 2. Block 28 and the second fixed block 29, the first fixed block 28 is provided with the second rotating motor 30,

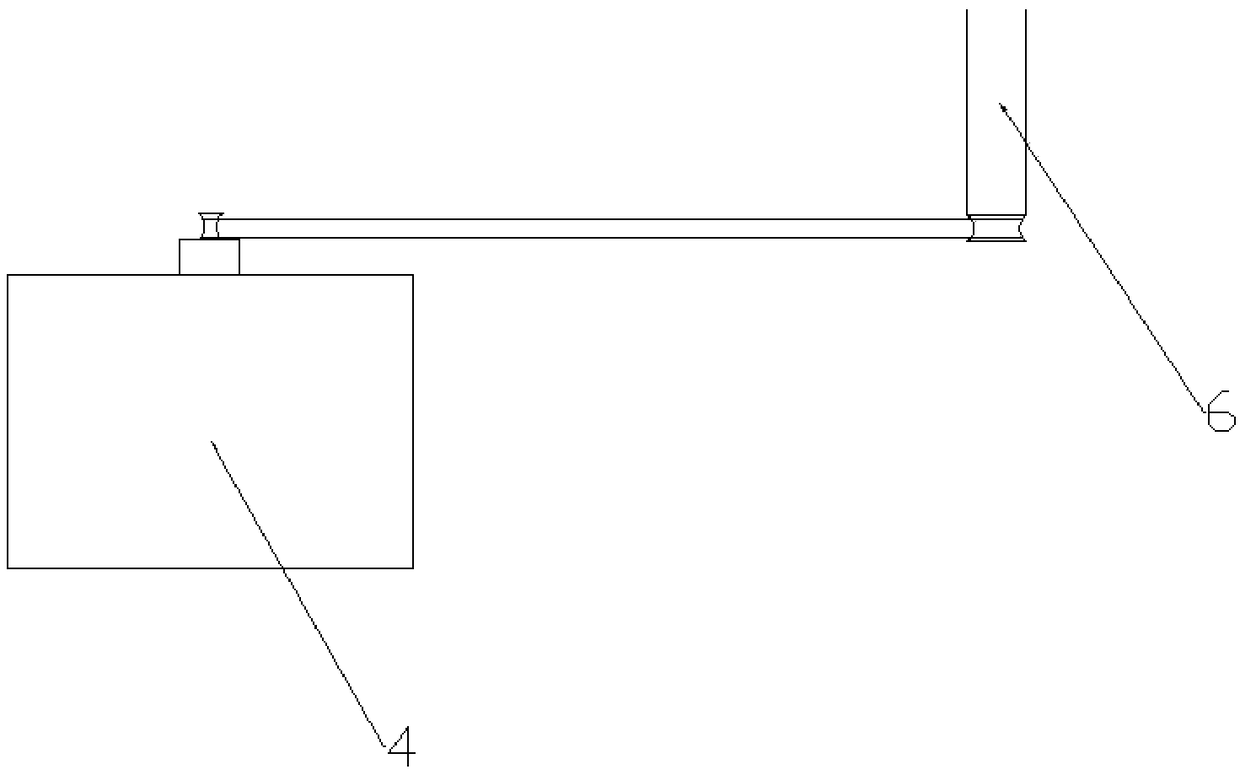

[0031] The operating table 1 is provided with four circularly distributed first rotating rods 5, the first rotating rod 5 is rotatably connected with a support frame 3, the lower part of the supporting frame 3 is rotatably connected with a second rotating rod 6, the first rotating Both the bottom ends of the rod 5 and the second rotating rod 6 are rotationally connected with the console 1 through the bearing 7; the second rotating rod 6 is connected with the output shaft of the first rotating motor 4 through a transmission belt; the top of the support frame 3 is provided with a square fixed Groo...

Embodiment 2

[0034] Such as Figure 1-6 As shown, the two ends of the second fixed block 29 are fixedly connected with the side of the fixed frame 2 and the circular movable platen 8 respectively, and the upper surface of the second fixed block 29 is on the same plane as the upper surface of the circular movable platen 8 superior;

[0035] When this embodiment is used, the upper surface of the second fixed block 29 and the upper surface of the circular movable platen 8 are on the same plane to ensure that the cleaning brush 32 is located on the second fixed block 29 during the pressing process, which will not affect the smooth progress of the pressing ; During the cleaning process, the cleaning brush 32 can automatically move from the second fixed block 29 to the circular movable platen 8 to clean the circular movable platen 8 .

Embodiment 3

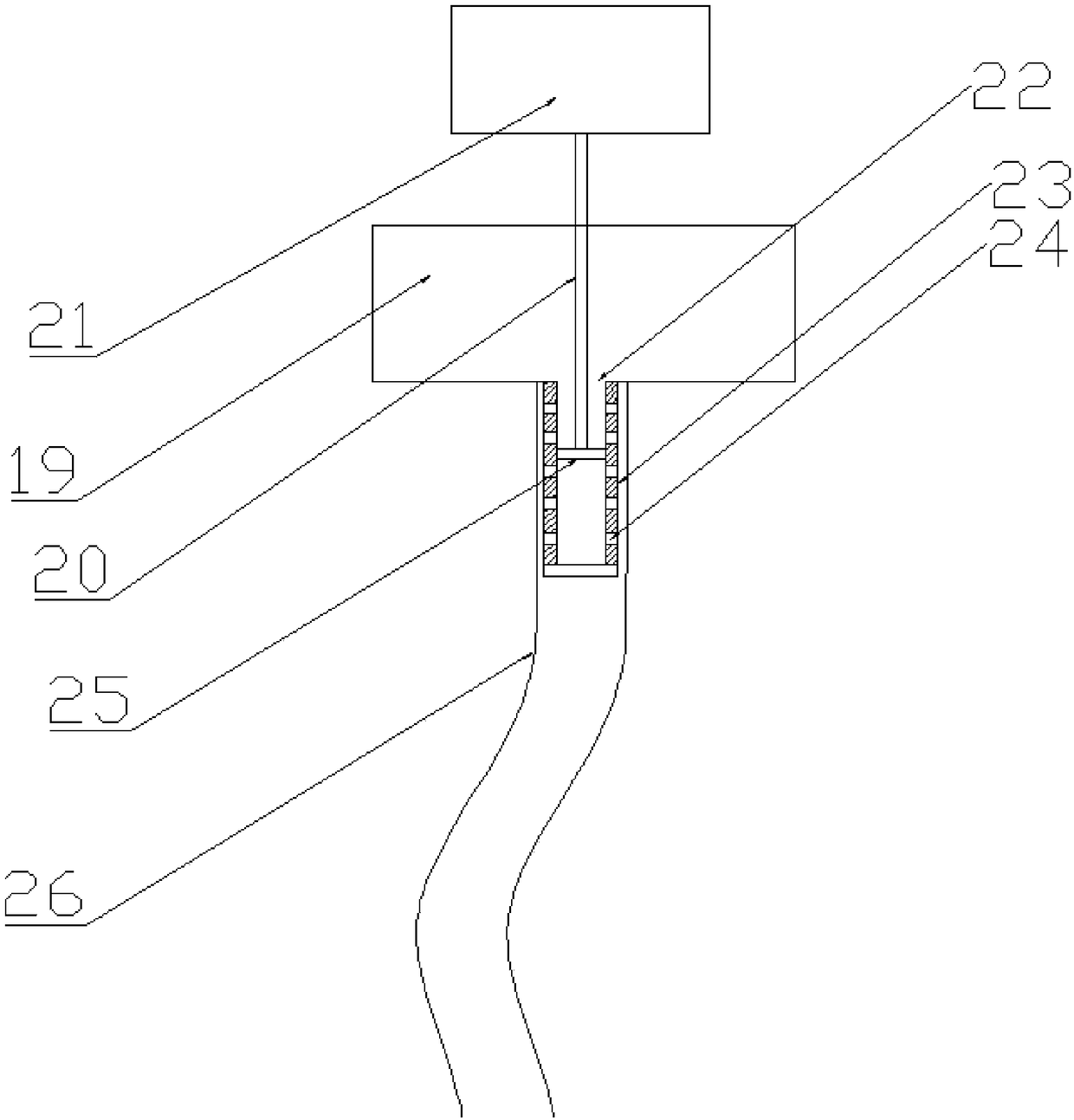

[0037] Such as Figure 4 As shown, the fixed pulley 31 is fixed on the fixed frame 2, and the fixed pulley 31 is located above the first fixed block 28; the output shaft of the first rotating motor 4 is concaved from both ends to form an arc;

[0038] When the present embodiment is in use, the fixed pulley 31 can change the direction of the wire rope 34, thereby ensuring that the second rotating motor 30 can drive the cleaning brush 32 to move horizontally on the circular movable pressing plate 8 through the wire rope 34; Both ends are concave inward to form an arc, which can ensure that the steel wire rope 34 will not slip out of the output shaft and cause cleaning to fail to proceed normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com