Novel 3D printer nozzle structure

A technology of 3D printers and nozzles, applied in the field of printing, can solve the problems of wasting manpower and time, lack of multi-color application, and poor viewing of items, etc., and achieve good circulation or interception, and facilitate thermal treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

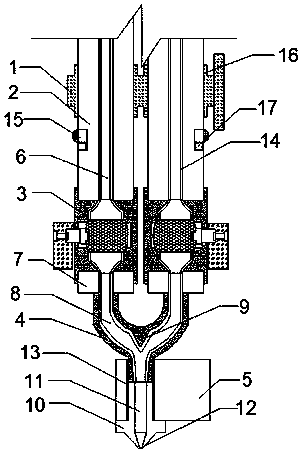

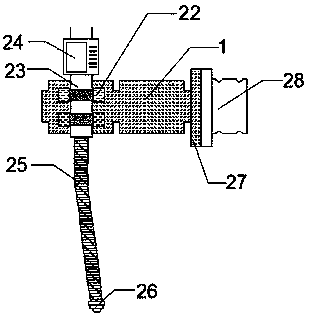

[0022] like Figure 1-3 As shown, a new 3D printer nozzle structure includes a sleeve frame 1, a delivery pipe 2, a miniature ball valve 3, a confluence pipe 4, and a heating head 5. 2. The bottom is threadedly connected to the threaded interface 18 of the mini ball valve 3 through the connector. The threaded interface 18 is located at the top and bottom of the mini ball valve 3. The bottom of the mini ball valve 3 is provided with a confluence pipe 4, and the top of the confluence pipe 4 is fixedly sleeved A confluence head 7, and the confluence head 7 is threadedly connected with the mini ball valve 3, the delivery pipe 2 has a material channel 6, the confluence pipe 4 has a confluence channel 8, and the material channel 6 communicates with the confluence channel 8 through the mini ball valve 3 connection, the bottom of the confluence pipe 4 is provided with a heating head 5, and the bottom of the confluence pipe 4 is embedded with the heating head 5, the sleeve frame 1 is u...

Embodiment 2

[0030] like Figure 1-3 As shown, a new 3D printer nozzle structure includes a sleeve frame 1, a delivery pipe 2, a miniature ball valve 3, a confluence pipe 4, and a heating head 5. 2. The bottom is threadedly connected to the threaded interface 18 of the mini ball valve 3 through the connector. The threaded interface 18 is located at the top and bottom of the mini ball valve 3. The bottom of the mini ball valve 3 is provided with a confluence pipe 4, and the top of the confluence pipe 4 is fixedly sleeved A confluence head 7, and the confluence head 7 is threadedly connected with the mini ball valve 3, the delivery pipe 2 has a material channel 6, the confluence pipe 4 has a confluence channel 8, and the material channel 6 communicates with the confluence channel 8 through the mini ball valve 3 connection, the bottom of the confluence pipe 4 is provided with a heating head 5, and the bottom of the confluence pipe 4 is embedded with the heating head 5, the sleeve frame 1 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com