Bonding equipment for bonding trim strips on glass panels

A technology for glass panels and decorative strips, which is applied in the direction of mechanical equipment, connecting components, and material gluing. It can solve the problems affecting the aesthetics of glass components, etc., and achieve less bonding processes, high bonding efficiency and precision, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

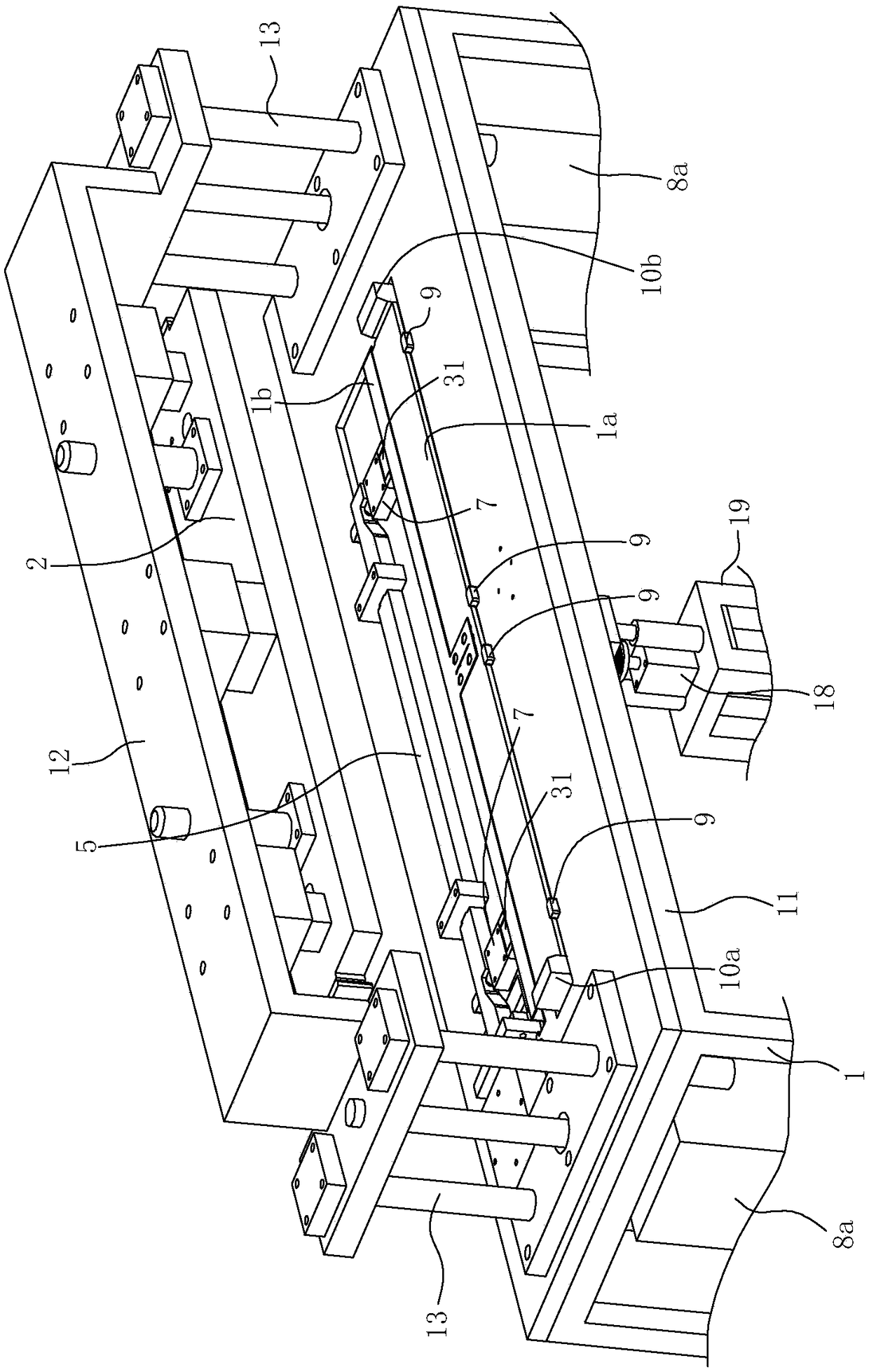

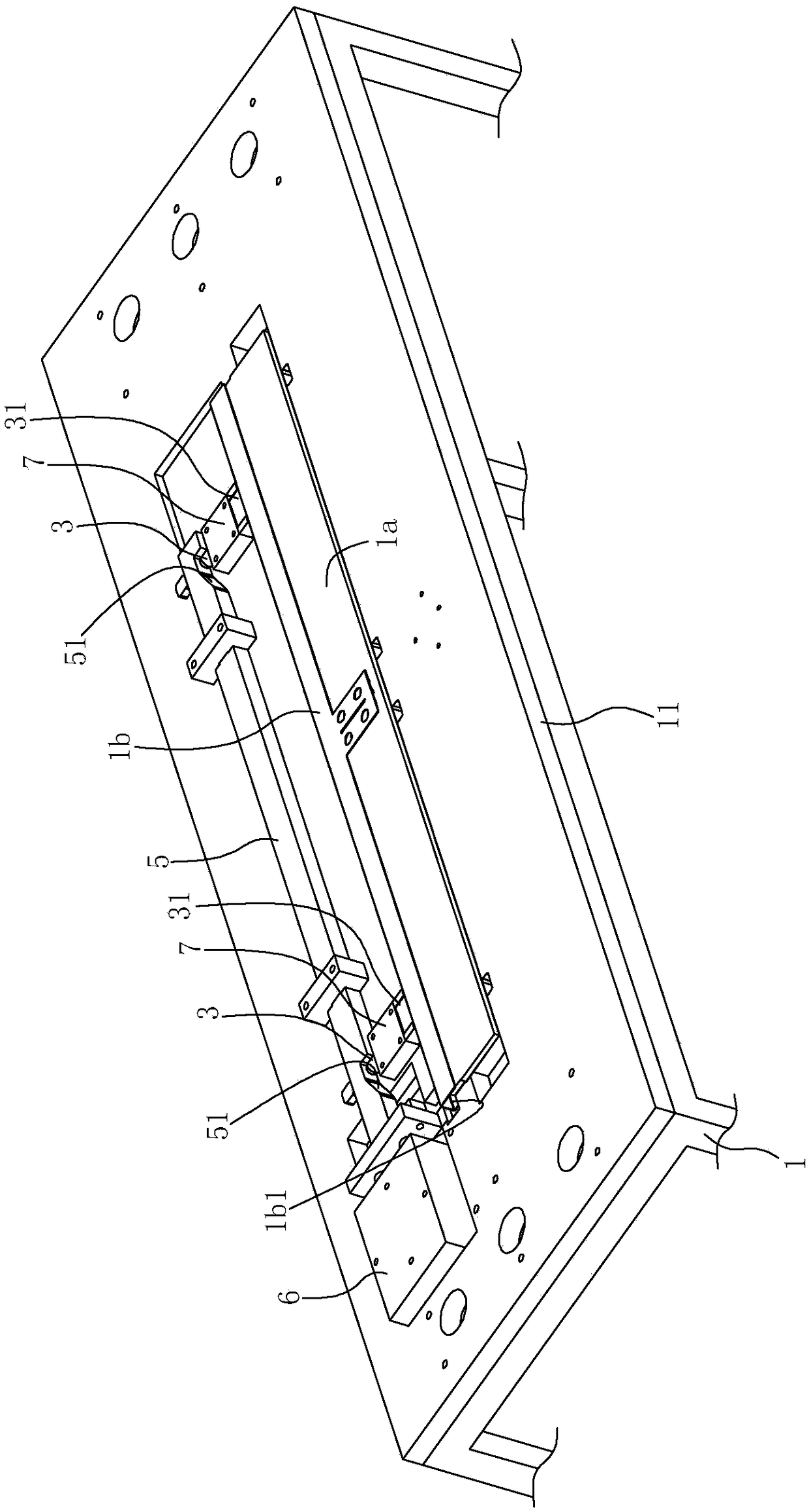

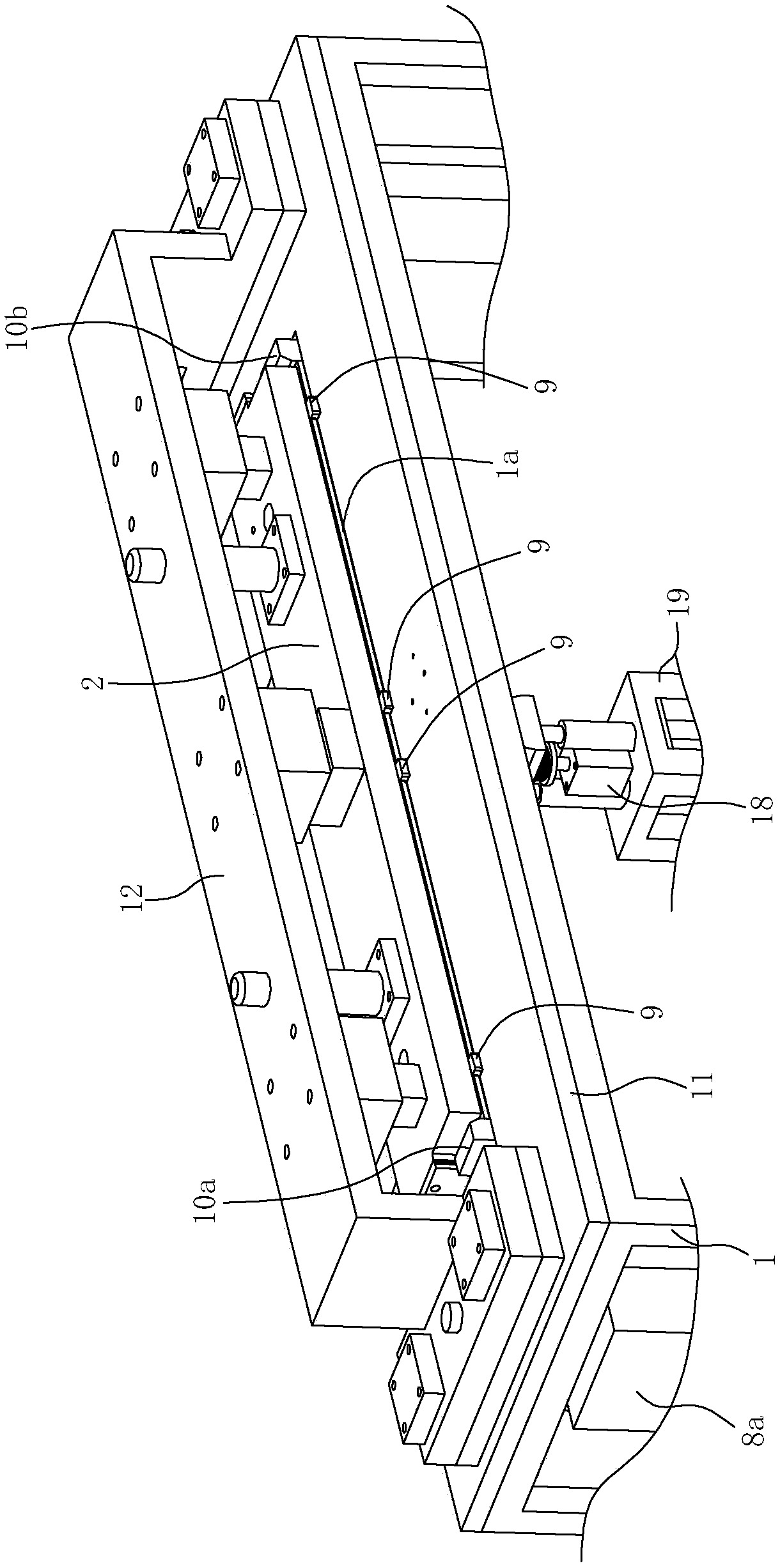

[0037] Such as Figure 1-16 Shown is a preferred embodiment of the present invention.

[0038] A bonding apparatus for bonding decorative strips to glass panels, comprising

[0039] The frame 1 has a working surface 11 for resting the glass panel 1a and the decorative strip 1b. The cross section of the decorative strip 1b is U-shaped, and the decorative strip 1b has a U-shaped bayonet 1b1.

[0040] Constraint structure, set on the worktable 11 to constrain and limit the glass panel 1a;

[0041] The upper platen 2 is located above the working surface 11 .

[0042] The frame 1 is provided with a mounting plate 12 positioned above the work surface, the mounting plate 12 is constrained on the work surface 11 by guide shafts 13 positioned on both sides and can move up and down, the upper pressing plate 2 is fixed on the mounting plate 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com