Conveying transition device of chemical fiber yarn

A technology of chemical fiber yarn and transition frame, applied in the field of chemical fiber, can solve problems such as complex structure, troublesome operation, and inability to adjust, and achieve the effect of convenient use, simple structure, efficient and accurate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The transmission transition device for chemical fiber filaments according to the present invention will be further described in detail through specific examples below.

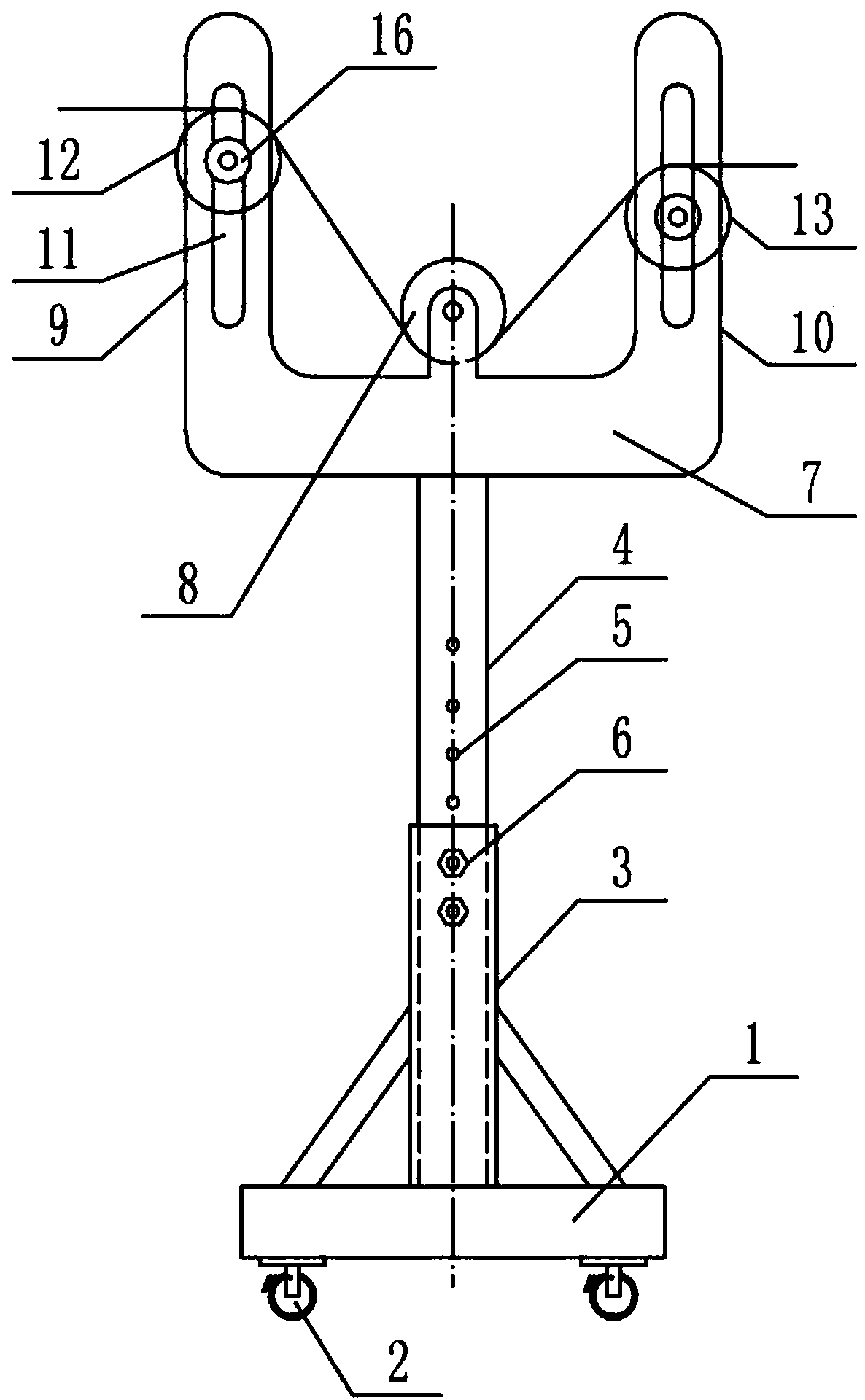

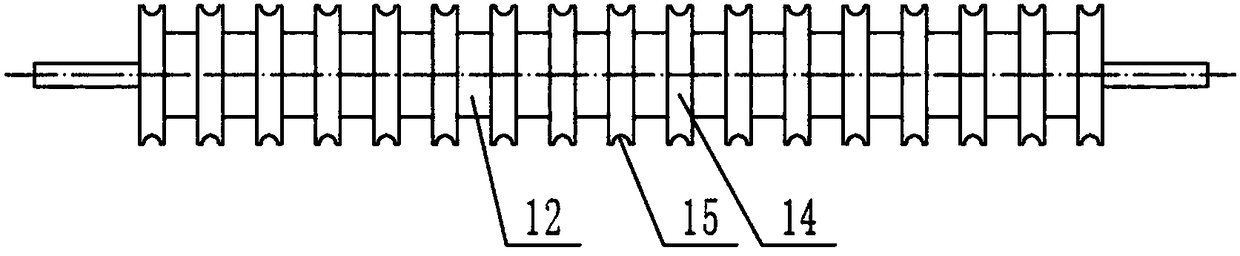

[0013] Such as figure 1 As shown, a transmission transition device for chemical fiber filaments includes a base 1, the bottom of which is provided with a universal wheel 2, and a column is provided on the base 1, and the column includes a fixed column 3 and a movable column 4, and the fixed column 3 is fixed with the base 1, and the movable column 4 is arranged in the fixed column 3, and a plurality of locking holes 5 are vertically arranged on the movable column 4, and a screw 6 is arranged on the fixed column 3, and the screw 6 passes through the locking hole 5 and then The movable column 4 is connected with the fixed column 3 . The column is provided with a transition frame 7, the middle part of the transition frame 7 is provided with a fixed roller 8, and a plurality of fixed wheels are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com