Automatic flexible freight bag overturning machine

A technology of automatically turning over and turning over motors, which is applied to lifting devices, hoisting devices, etc., can solve the problems of physical and mental health of operators, impact on workshop environment, high labor intensity of workers, and long feeding time, etc. The effect of dust suppression and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

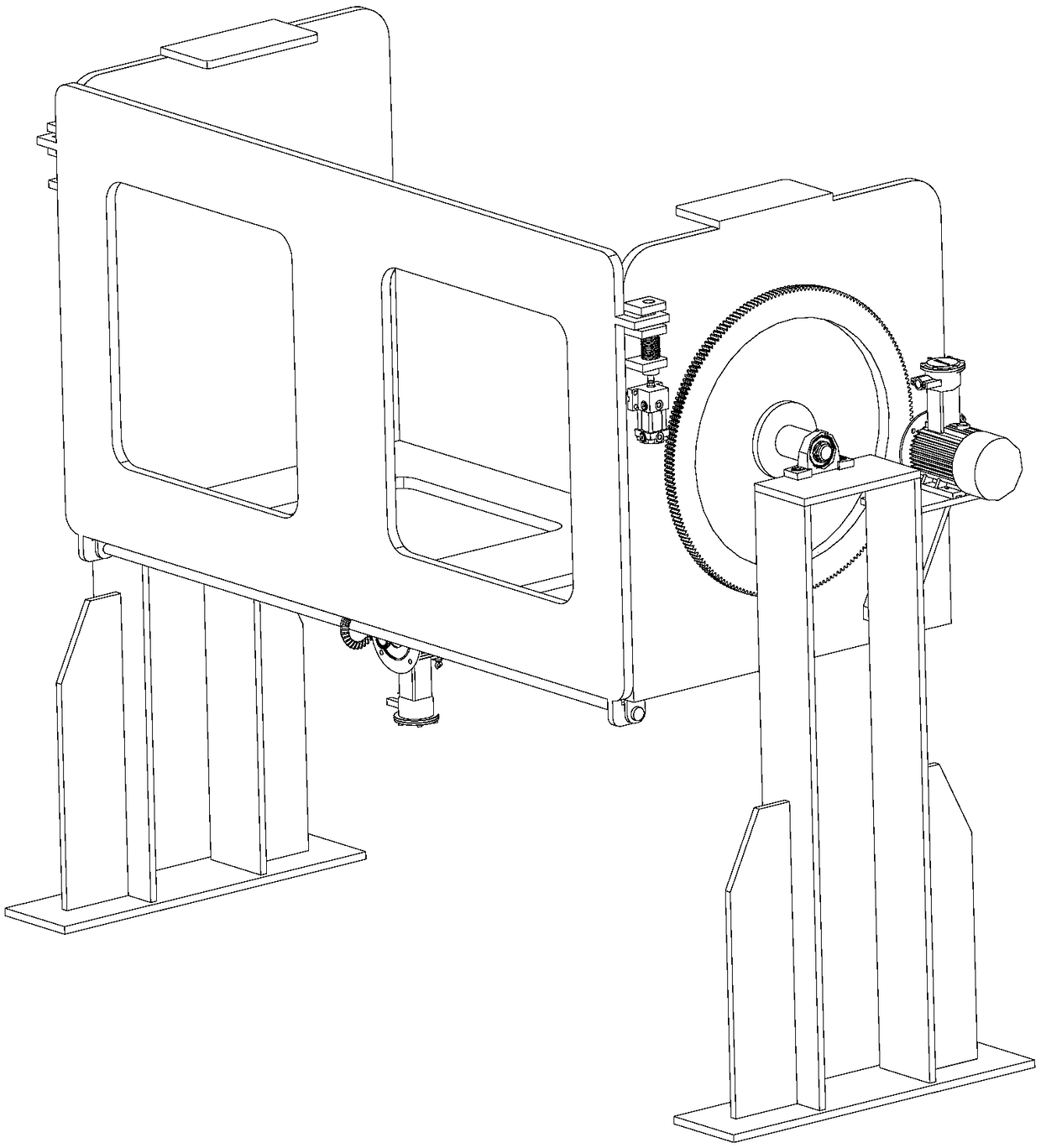

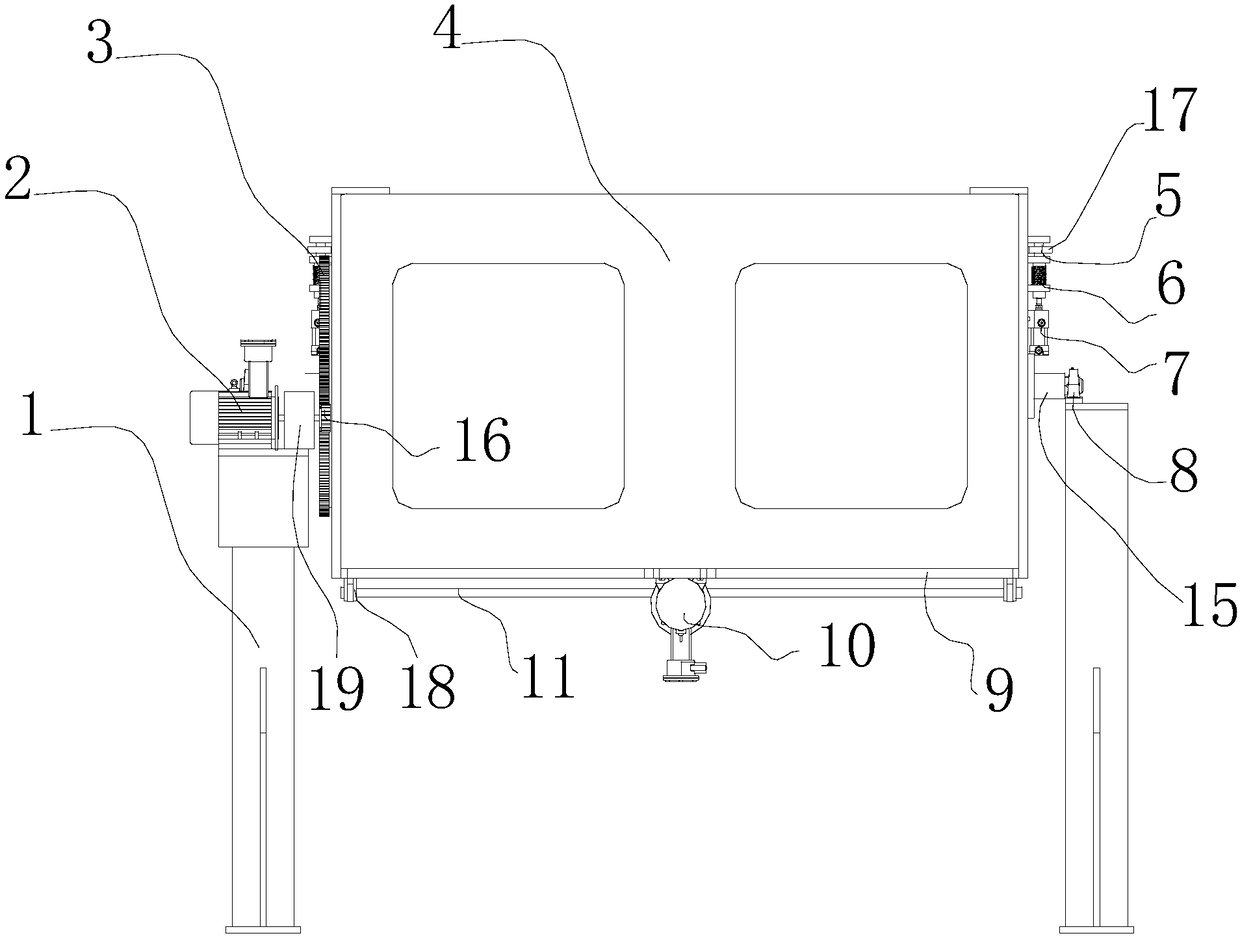

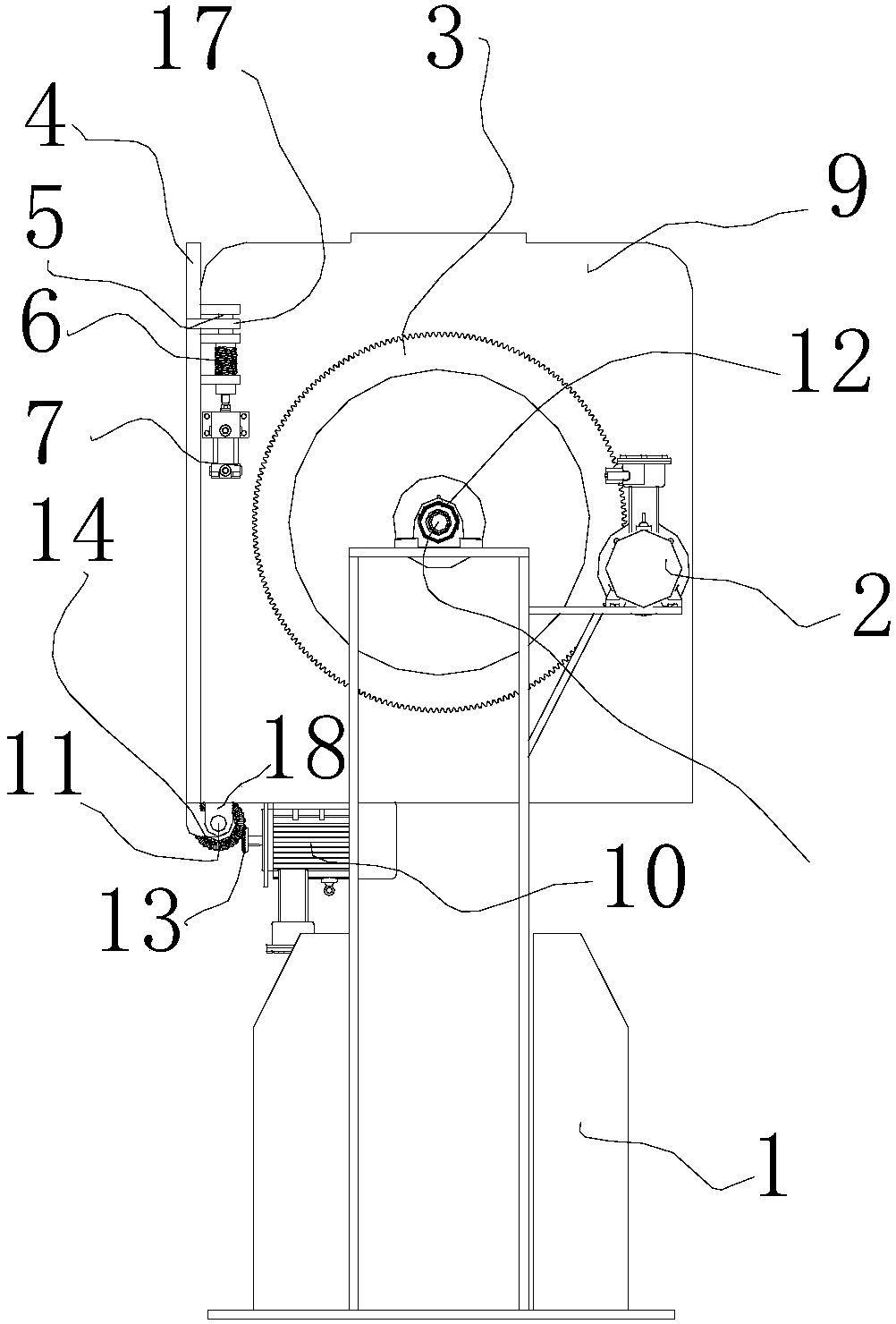

[0024] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] like Figure 1-4 A ton bag automatic turning machine shown includes a bracket 1, a turning explosion-proof motor 2, a large gear 3, a rear cover 4, a locking pin 5, a spring 6, a hydraulic cylinder 7, a bearing seat 8, and a U-shaped box 9 , rear cover explosion-proof motor 10, rotating shaft 11, bearing block 12, small bevel gear 13, large bevel gear 14, turning shaft 15, pinion 16, rear cover plate lock 17, fixed hinge 18 and electromagnetic lock 19.

[0026] The two ends of the U-shaped box 9 are respectively fixed with the turning shaft 15, the turning shaft 15 is installed on the bearing seat 8, the bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com