An automatic slag cleaning machine for narrow gap mag/mig welding

A narrow gap, slag cleaning machine technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of less than 100% removal rate, adverse effects on the stability of the welding process, etc., to achieve qualified weld quality It is beneficial to improve the efficiency, to prevent welding process defects, and to improve the productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

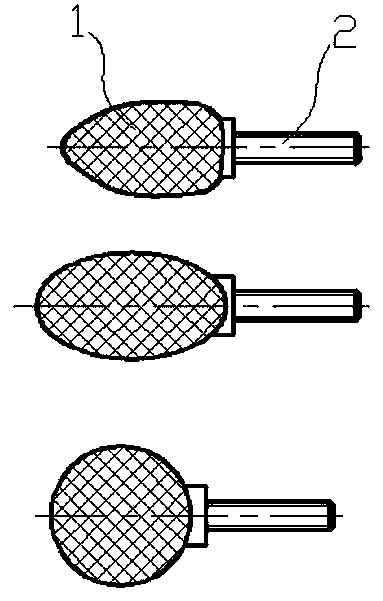

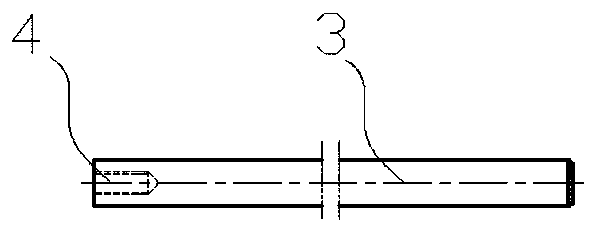

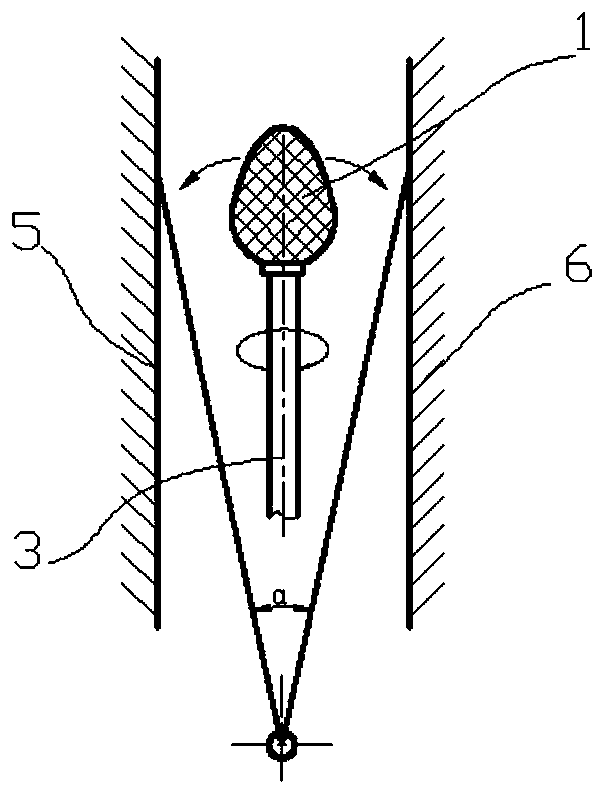

[0023] The automatic slag cleaning machine of the present invention is mainly composed of a rotary file 1, a rotary file handle 2, a protruding file handle 3, a screw hole 4, a welding groove side wall 5 on one side, a welding groove side wall 6 on the other side, and a file handle Seat 7, gearbox 8, driving gear 9, driven gear 10, hinge shaft 11 and stepping motor 12 form.

[0024] The rotary file 1 is a hard alloy rotary file, its blade is helical and sintered; its shape is conical, olive-shaped or spherical according to whether the welding seam is circular or straight. The handle of the rotary file is a stud, so that after connecting with the extension file handle, the cutting edge is used to crush and remove the deoxidation products on the surface of the weld. The extension file handle 3 is a round rod structure, and the type 304 or 316 is selected. stainless steel material.

[0025] The function of the sway mechanism is to drive the protruding file handle and drive the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com