Method for spraying paint to boards

A technology of wood boards and paints, applied to the device and coating of the surface coating liquid, which can solve the problems of low efficiency and achieve the effects of improving production efficiency, increasing leveling effect, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

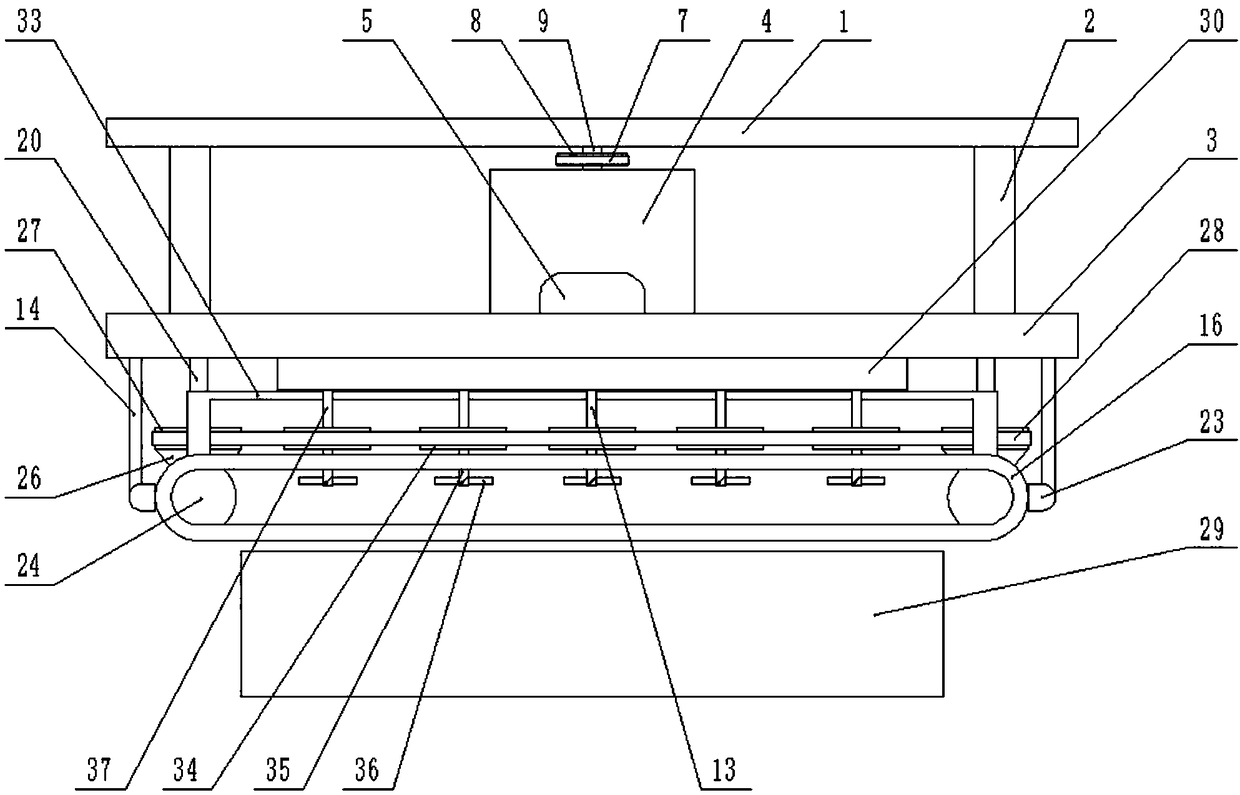

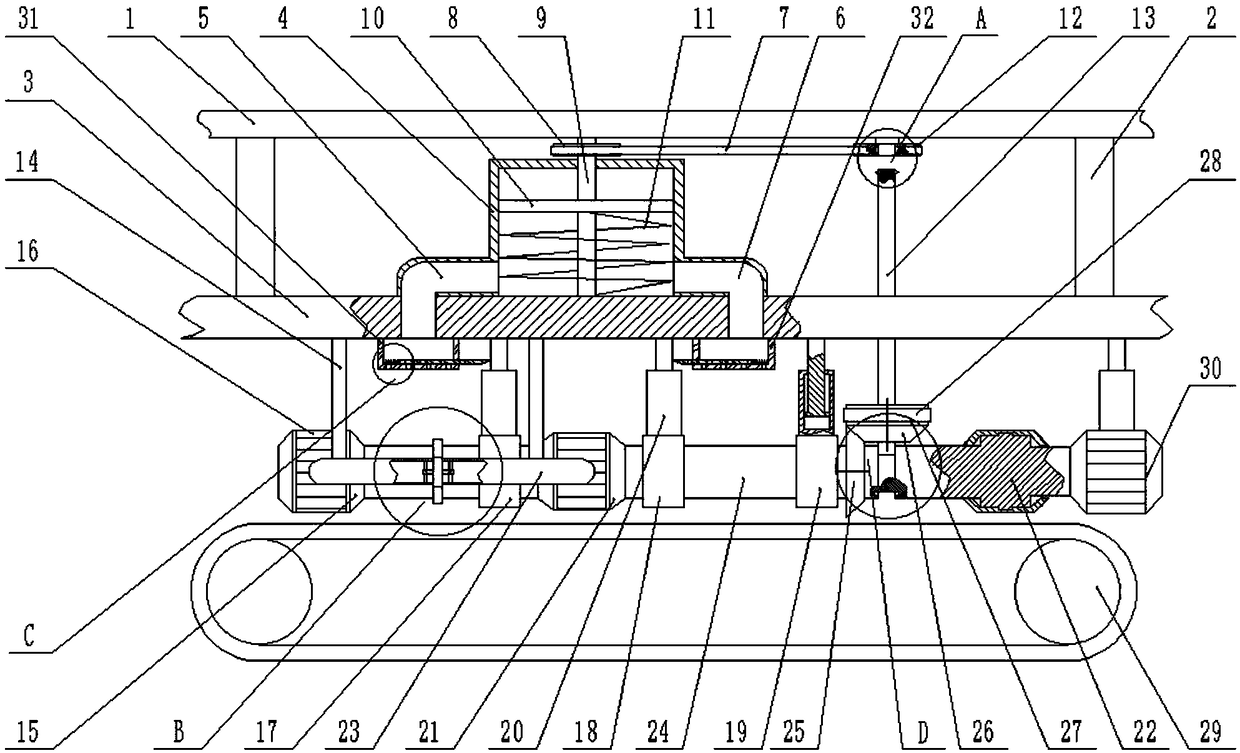

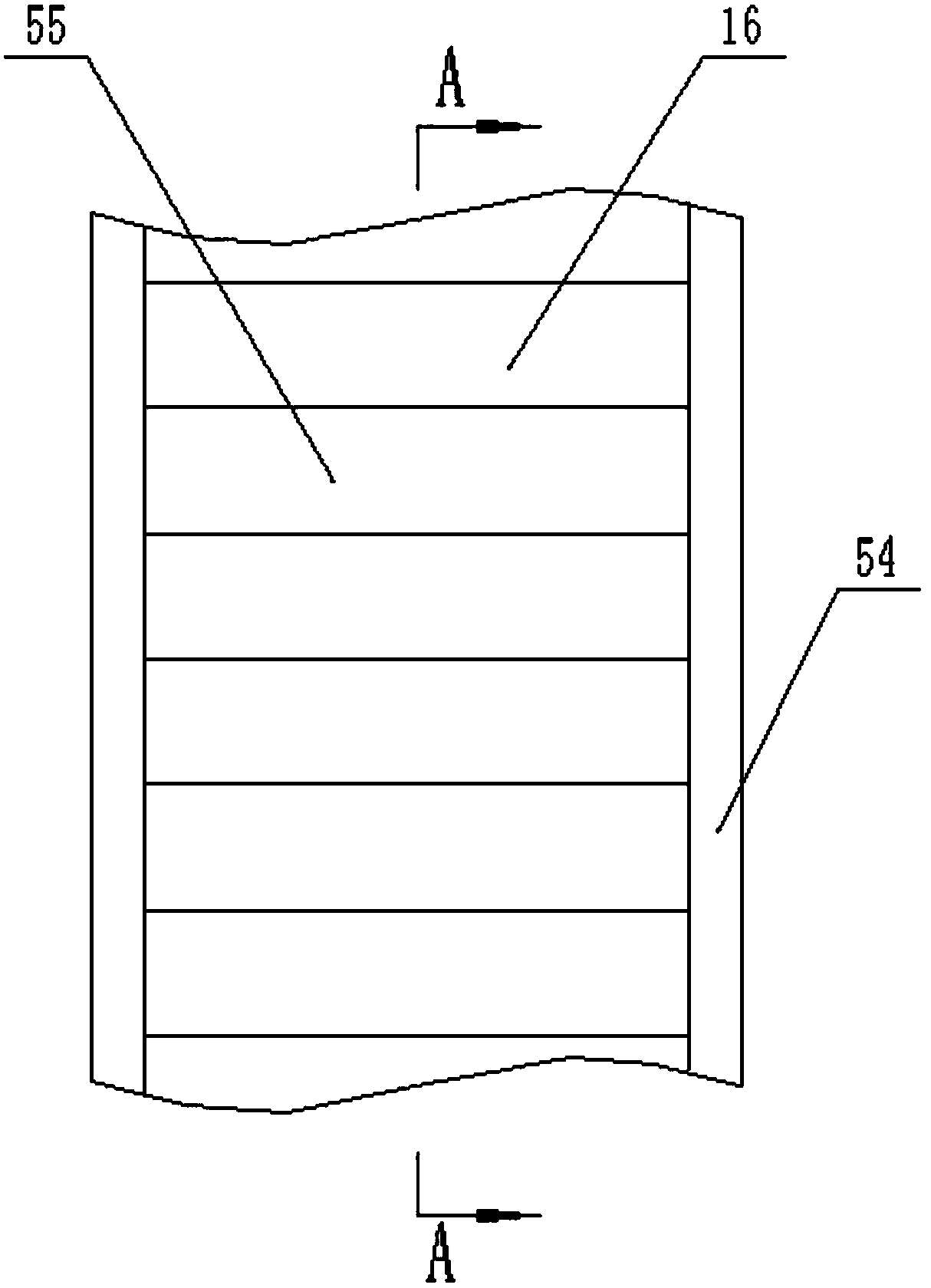

[0027] The reference signs in the drawings of the description include: frame 1, connecting rod 2, partition 3, liquid storage tank 4, first infusion tube 5, second infusion tube 6, belt 7, driven infusion pulley 8, wire Bar 9, piston plate 10, return compression spring 11, active infusion pulley 12, paint spraying drive shaft 13, boom 14, first grinding pulley 15, grinding belt 16, first positioning collar 17, second positioning collar 18. The third positioning collar 19, the telescopic rod 20, the second grinding pulley 21, the polishing pulley 22, the air duct 23, the drive shaft 24, the first bevel gear 25, the second bevel gear 26, and the drive sprocket 27 , roller chain 28, conveyor belt 29, motor 30, the first paint spray box 31, the second paint spray box 32, the first push bar 33, driven sprocket 34, the second rotating shaft 35, paddle 36, telescopic rotating shaft 37, Dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com