a crusher

A crusher and tertiary crushing technology, used in solid separation, chemical instruments and methods, grain processing, etc., can solve the problems of poor crushing effect, inconvenient operation and high cost, and achieve the effect of improving crushing effect and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

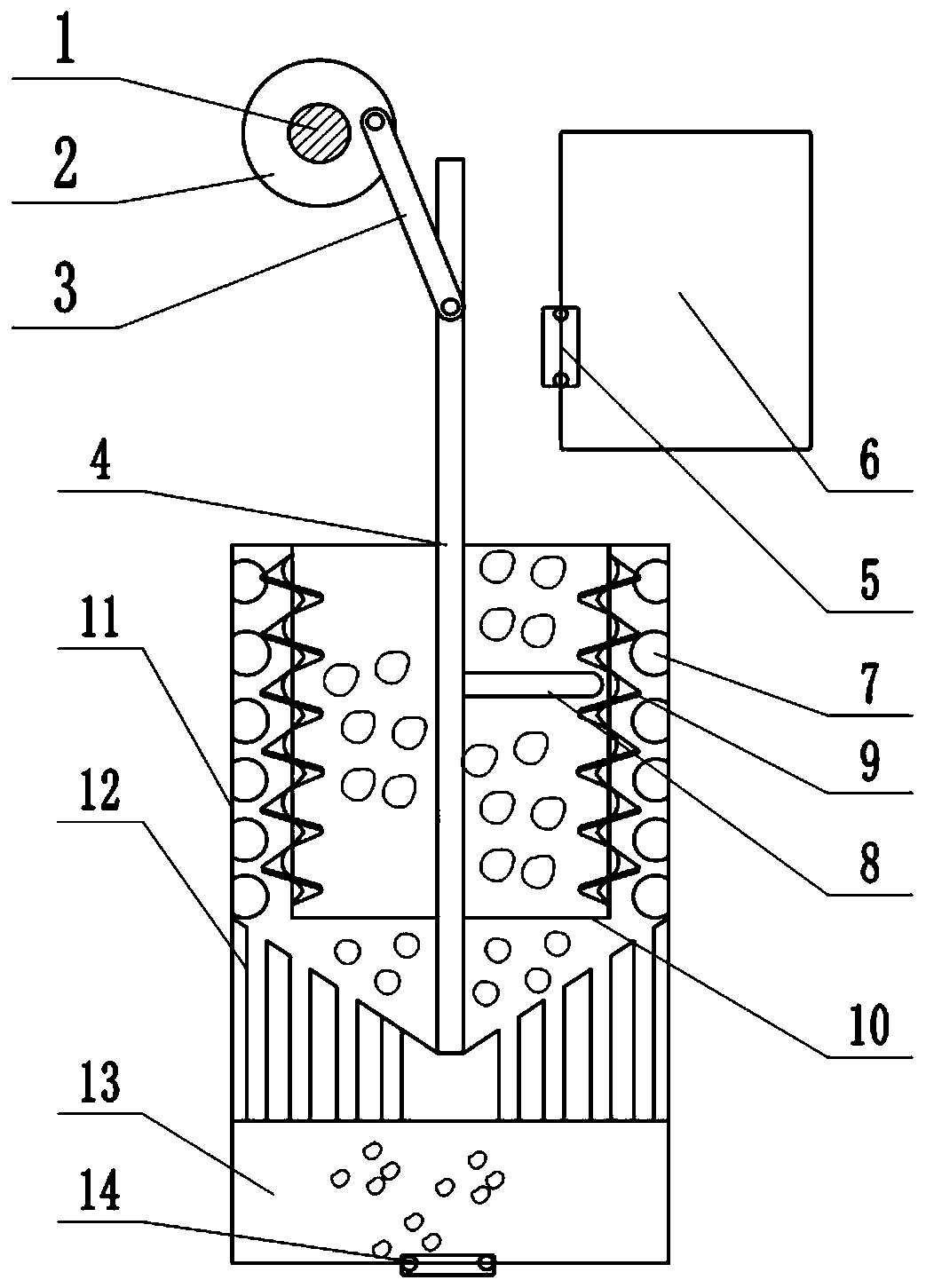

[0020] Such as figure 1 As shown, a crusher includes a drive unit, the drive unit includes a motor 1, the output shaft of the motor 1 is connected to a disc 2, the disc 2 is hinged to a connecting rod 3, and the connecting rod 3 is hinged to a sliding rod 4 that can move up and down. The upper part of the slide bar 4 is fixedly connected with a threaded rod 8, one side of the drive unit is provided with a feed box 6, one side of the feed box 6 is provided with a one-way feed door 5, and the bottom of the feed box 6 is provided with a crushing unit. The unit includes a primary crushing part, a secondary crushing part and a tertiary crushing part. The primary crushing part includes a crushing box. The crushing box includes an outer wall 11 and an inner wall 10 rotatably connected to the outer wall. The inner wall 10 is a hollow structure. There is an opening for the material in the feed box 6 to enter, and the lower end of the inner wall 10 is provided with a port for the slide ...

Embodiment 2

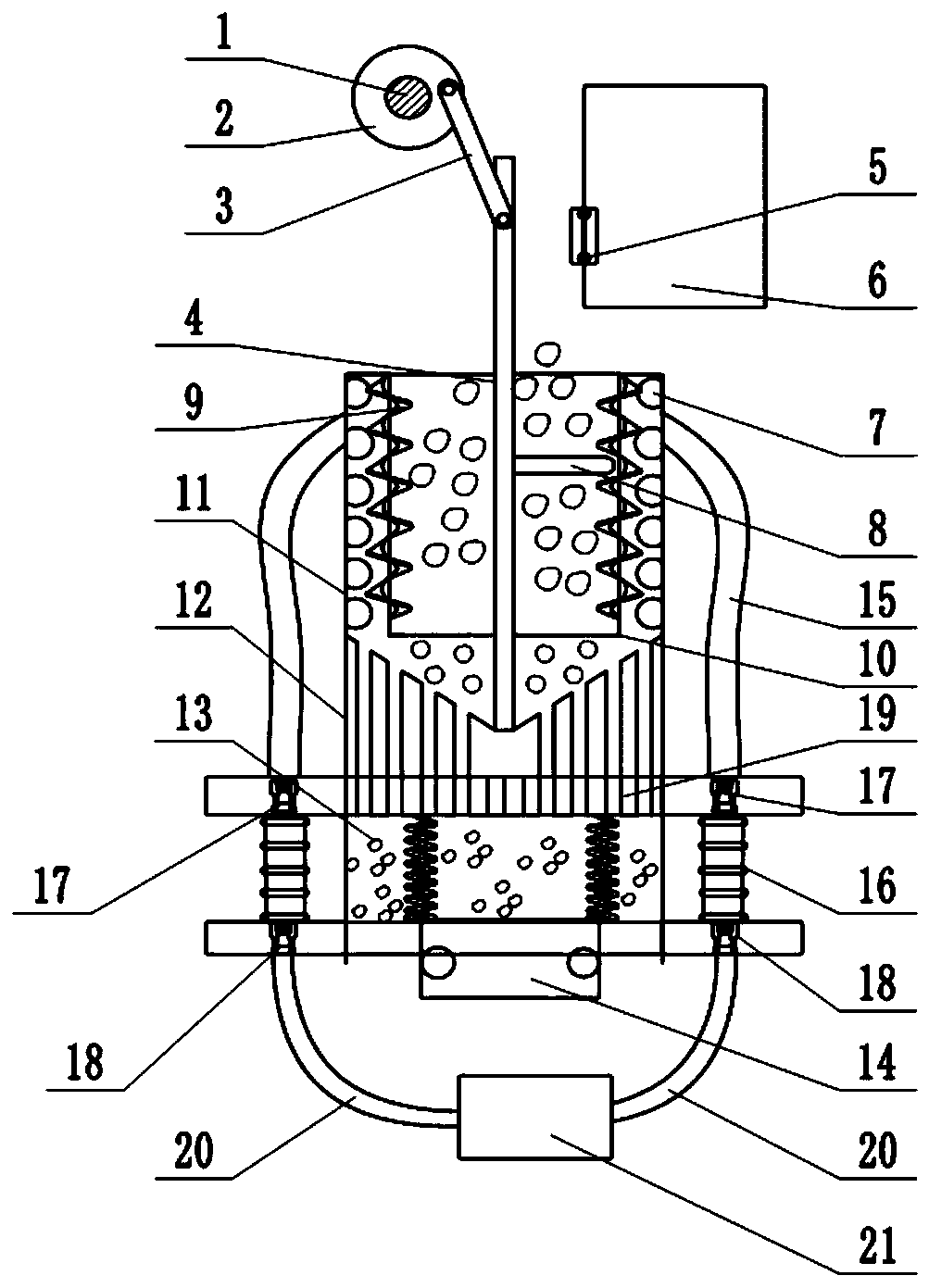

[0023] The difference between this embodiment and Embodiment 1 is that: figure 2 As shown, the upper end of the third-stage crushing part is provided with a rigid sieve plate that is opposite to the loophole of the leakage screen 12 and is slidably connected with the outer wall 11. The two ends of the rigid sieve plate protrude from the outer wall 11 of the crushing box. One end of the spring is connected to the lower end of the third-stage crushing part. Both ends of the rigid sieve plate are provided with bellows 16 connected to the lower end of the third-stage crushing part. The upper end of the bellows 16 is provided with a negative pressure check valve 17 facing the lower end of the third-stage crushing part. The negative pressure one-way valve 17 is connected with the first pipeline 15 extending into the outer wall 11, the lower end of the bellows 16 is provided with a positive pressure one-way valve 18 towards the outside of the lower end of the third-stage crushing par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com