A kind of modified chitosan/sulfonated polyethersulfone cation exchange membrane and its preparation method

A technology of cation exchange membrane and sulfonated polyethersulfone, which is applied in the field of modified chitosan/sulfonated polyethersulfone cation exchange membrane and its preparation, can solve the problem of high membrane surface resistance and difficult problems of chitosan and polyethersulfone Direct compounding and other issues to achieve the effect of improving porosity, excellent mechanical strength and stability, and delaying the service life of the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

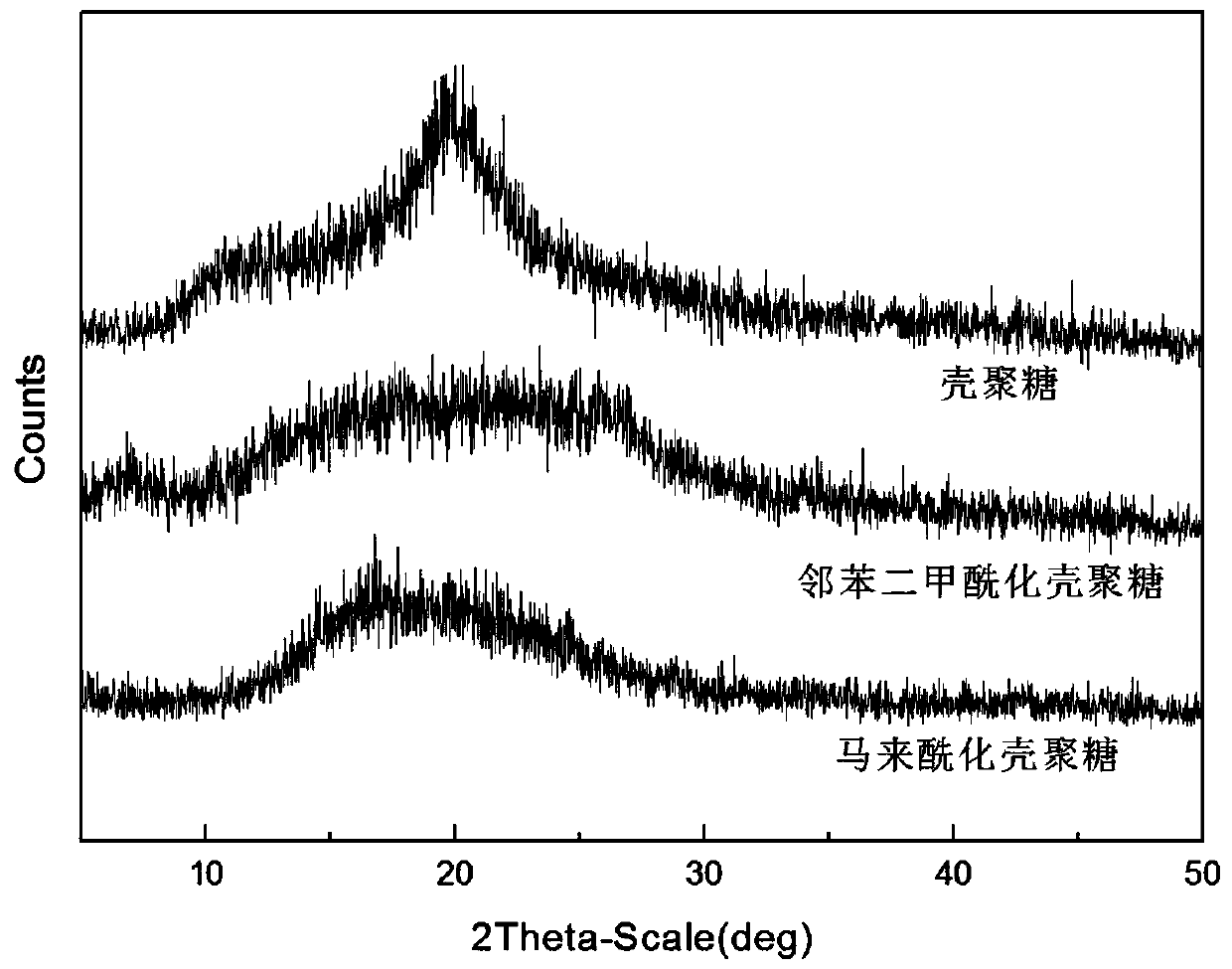

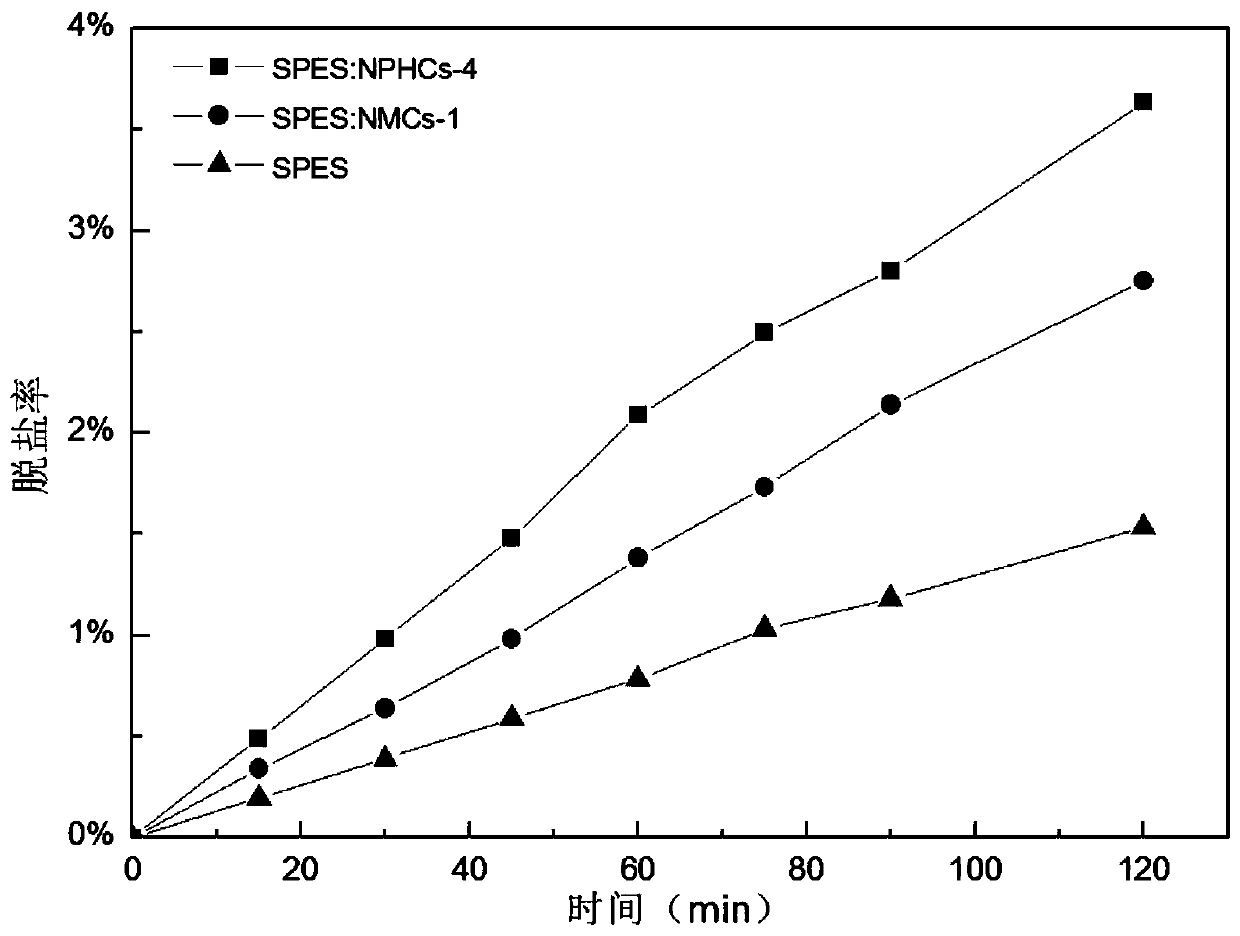

Embodiment 1

[0020] 4g of phthalic anhydride was dissolved in 18g of N,N-dimethylformamide, 1g of chitosan was added, and N 2 Stir and react in the atmosphere, then pour into a large amount of ice water, filter, wash with ethanol, and dry to obtain phthalylated chitosan. 4g polyethersulfone dissolved in 50g methylene chloride, N 2 Under protection, add 8g of chlorosulfonic acid and 2g of concentrated sulfuric acid to react, pour into a large amount of ice water, filter, wash with methanol, and dry to obtain sulfonated polyethersulfone. 0.5g of phthalylated chitosan and 9.5g of sulfonated polyethersulfone were dissolved in 90g of N-methylpyrrolidone, stirred and reacted at 55°C, filtered under reduced pressure, and left to stand for a period of time for defoaming treatment to obtain a casting solution . Pour the casting solution onto a clean glass plate to coat the film, dry it, soak it in deionized water, and remove it. The prepared cation exchange membrane is marked as SPES:NPHCs-1.

...

Embodiment 2

[0023] 3g of phthalic anhydride was dissolved in 19g of N,N-dimethylacetamide, 0.7g of chitosan was added, and N 2 Stir and react in the atmosphere, then pour into a large amount of ice water, filter, wash with ether, and dry to obtain phthalylated chitosan. 3.5g polyethersulfone dissolved in 50g chloroform, N 2 Under protection, 11 g of chlorosulfonic acid was added for reaction, poured into a large amount of ice water, filtered, washed with methanol, and dried to obtain sulfonated polyethersulfone. 0.8g of phthalylated chitosan and 7.2g of sulfonated polyethersulfone were dissolved in 72g of N,N-dimethylformamide, stirred and reacted at 60°C, filtered under reduced pressure, and left to stand for a period of time for defoaming treatment. Obtain casting solution. Pour the casting liquid onto a clean glass plate to coat the film, dry it, soak it in deionized water, and remove it. The prepared cation exchange membrane is marked as SPES:NPHCs-2.

[0024] The contact angle and...

Embodiment 3

[0026] 4g of phthalic anhydride was dissolved in 15g of N,N-dimethylacetamide, 0.9.g of chitosan was added, and at 130°C, N 2 Stir and react in the atmosphere, then pour into a large amount of ice water, filter, wash with ethanol and ether, and dry to obtain phthalylated chitosan. 4g polyethersulfone dissolved in 55g methylene chloride, N 2 Add 12g of oleum to react under protection, pour into a large amount of ice water, filter, wash with ethanol, and dry to obtain sulfonated polyethersulfone. 1g of phthalylated chitosan and 9g of sulfonated polyethersulfone were dissolved in 90g of N-methylpyrrolidone, stirred and reacted at 70°C, filtered under reduced pressure, left to stand for a period of time for defoaming treatment, and a casting solution was obtained. Pour the casting liquid onto a clean glass plate to coat the film, dry it, soak it in deionized water, and remove it. The prepared cation exchange membrane is marked as SPES:NPHCs-3. The contact angle and ion exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com