Medical transferring bed

A transfer bed and flexible belt technology, applied in medical transportation, hospital beds, medical science, etc., can solve the problems of patients with large range of body movement, reduced gravity, and increased strength of guide rollers, so as to reduce the risk of secondary injuries , the risk of secondary injury is low, and the effect of reducing the safety distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

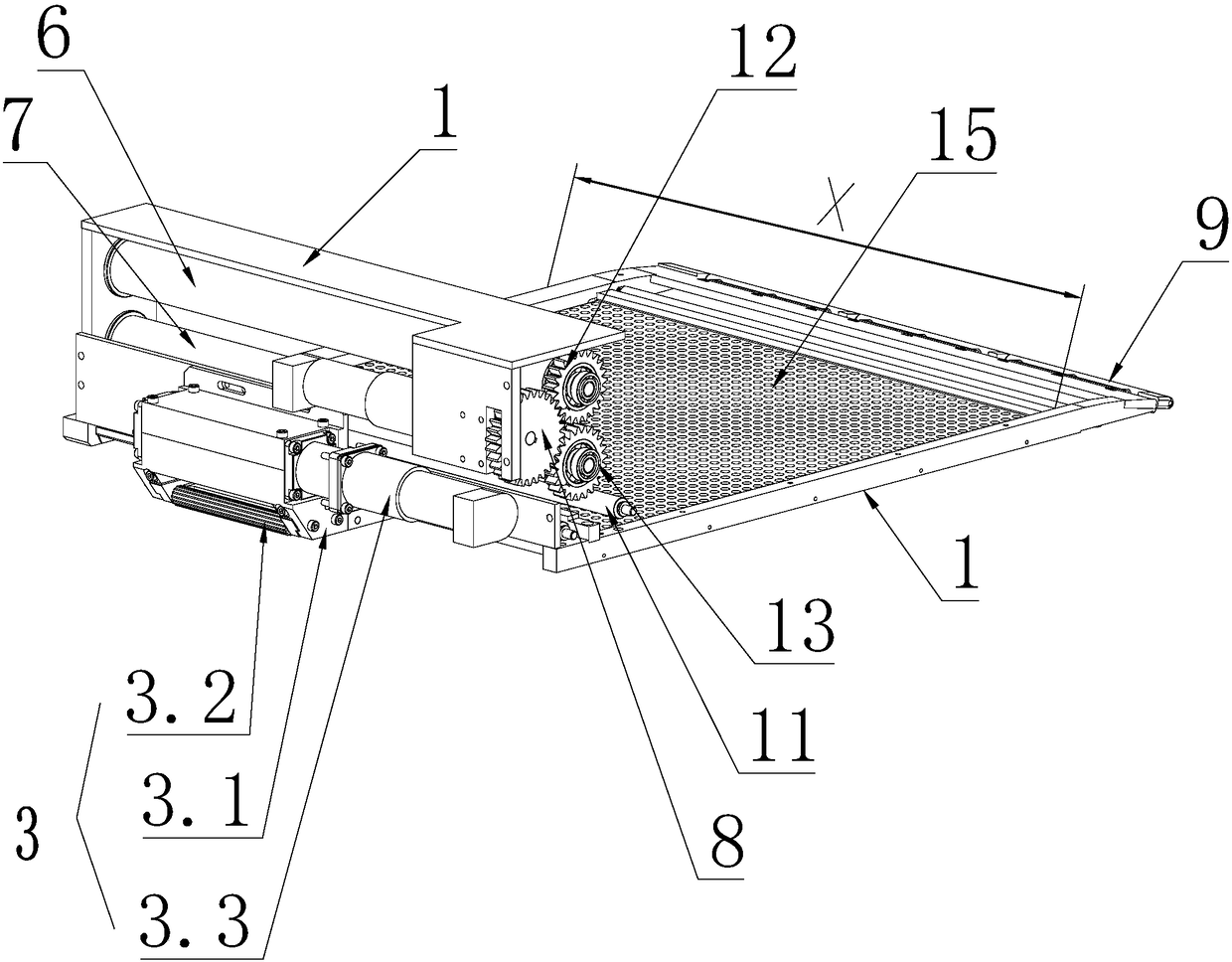

[0063] The invention provides a transfer bed for medical care, which includes such as figure 1 or Figure 7 Shown frame 1 and flexible belt 2, flexible belt 2 is arranged on the frame 1, and the bottom of frame 1 is provided with running gear 3, is used to drive frame 1 to move, and the top of described running gear is provided with for bearing The working area of the patient, the part of the flexible belt located in the working area is tightened to form a supporting surface for lifting the patient, and it is characterized in that it also includes an equipment installation area outside the working area. A drive roller assembly is provided in the equipment installation area, and a guide roller assembly is provided on the side away from the equipment installation area in the working area. The drive roller assembly and the guide roller assembly cooperate with each other to drive the The flexible belt outside the assembly and the guide roller assembly moves along its own length...

Embodiment 2

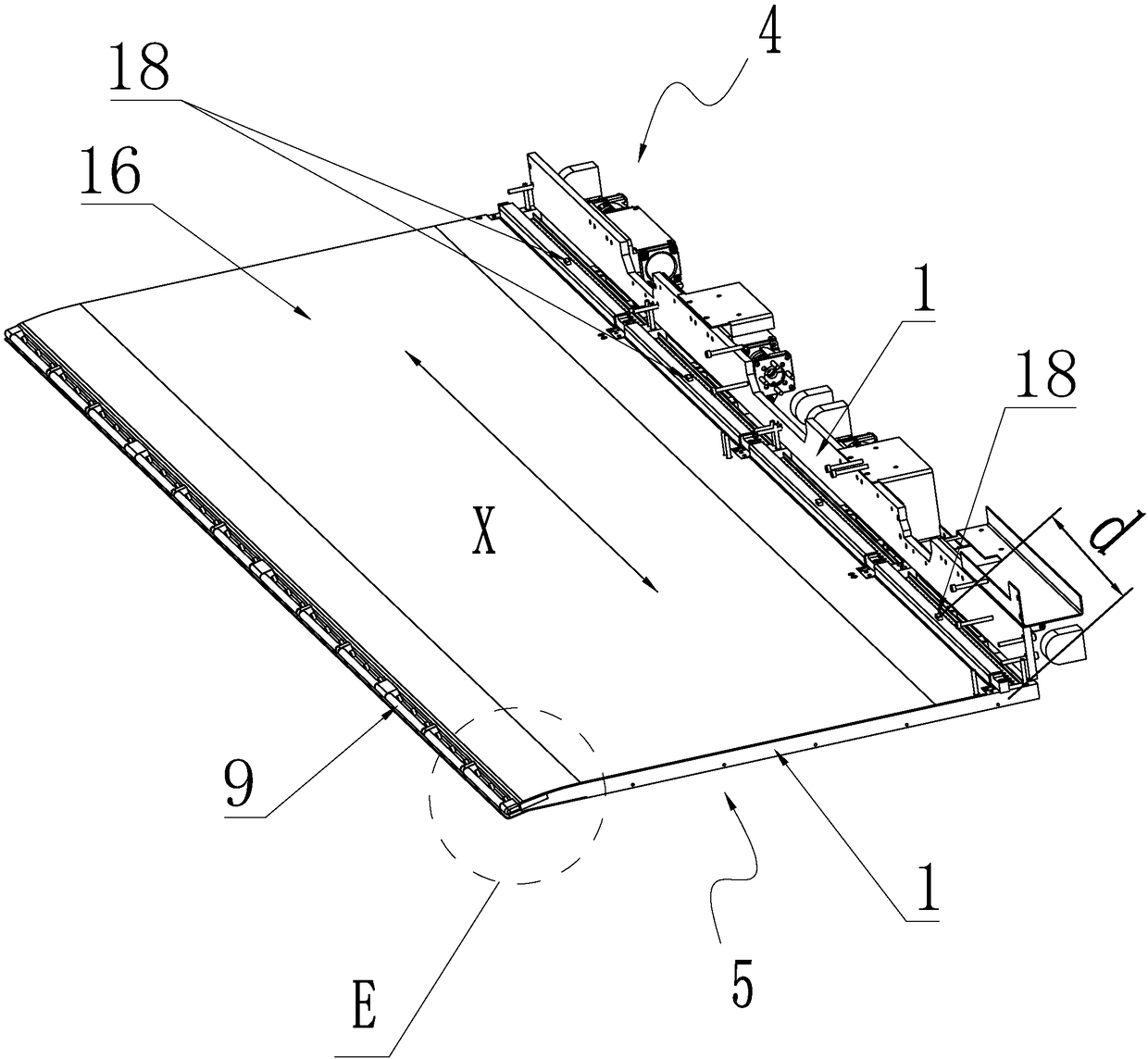

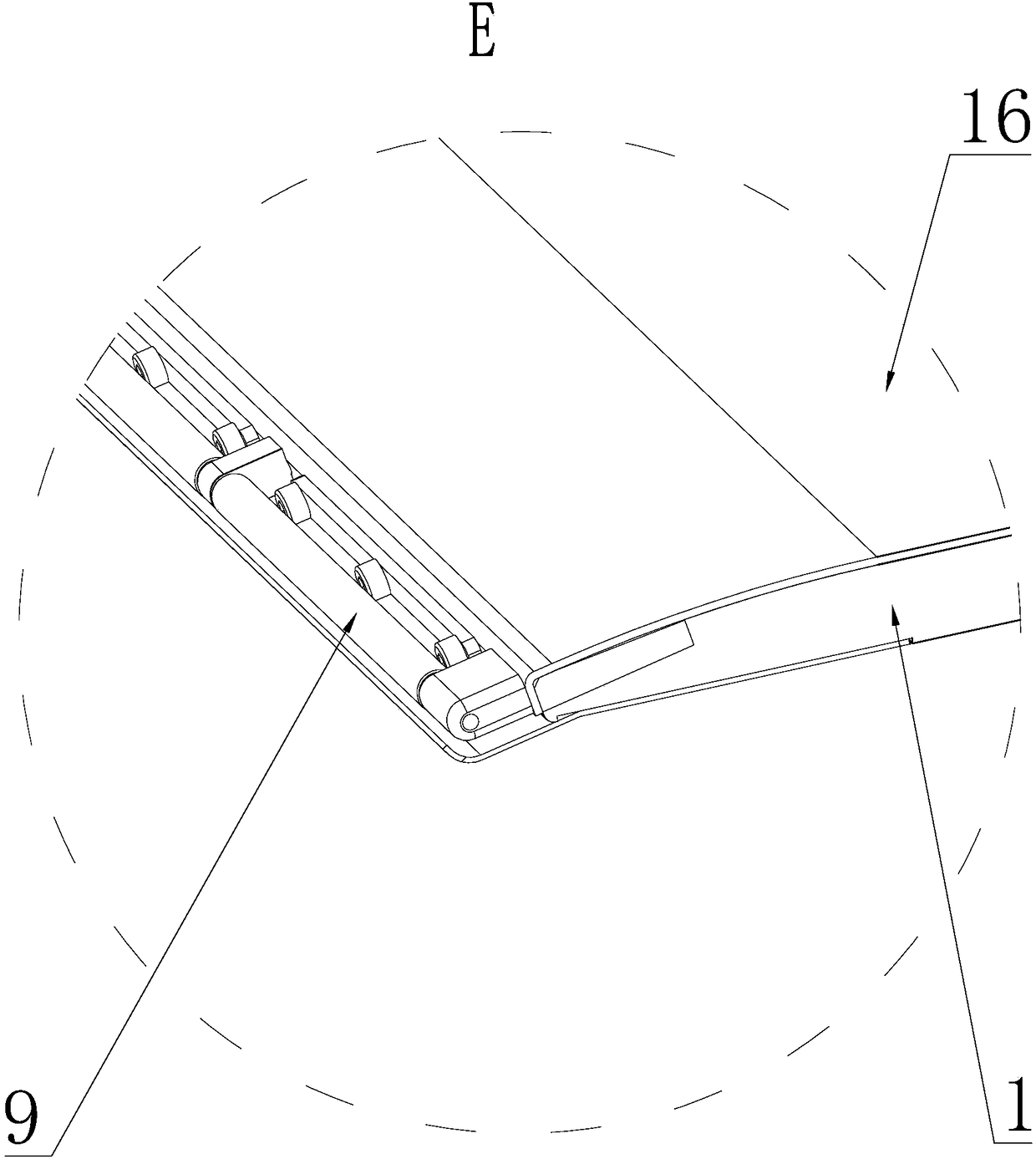

[0067] The driving roller assembly includes a driving shaft, and the driving shaft rotates with the frame 1 along the circumference of its own axis, and the guide roller assembly includes a front roller 9, and the above-mentioned flexible belt 2 is wound around the outside of the driving roller assembly Winding the flexible belt 2 around the outside of the guide roller assembly means that the inner side walls of the flexible belt 2 are respectively placed outside the drive shaft and the front roller 9, and the flexible belt is in a tight state, and the flexible belt 2 is located in the working area 5 The part of the flexible belt 2 is tightened to form a platform 2.1 for carrying the patient. The structure of the flexible belt 2 located on the part of the platform 2.1 is a double-layer flexible belt structure. The upper area of the upper flexible belt 2.2 forms a transfer space 10 for accommodating the patient. The equipment installation area is provided with a drive transfer...

Embodiment 3

[0079] The walking unit includes a walking support 3.1, which is fixed on the bottom of the frame 1, and a plurality of mutually parallel rolling shafts are arranged at intervals along the horizontal direction on the walking support 3.1, and the described frame 1 or walking The support 3.1 is provided with a travel driver 3.3 for driving the rotation of the rolling shaft.

[0080] Such as Figure 16 to Figure 23 As shown in any view in , there are multiple flexible belts 2, and the multiple flexible belts 2 are sequentially arranged at intervals along the width direction X of the rack 1, and the equipment installation area 4 is located in the corresponding flexible belt 2 The corresponding upper rollers 6, lower rollers 7 and transfer drivers 8 are provided at the corresponding positions, and the corresponding front rollers 9 are provided at the corresponding positions of the flexible belts 2 in the working area 5.

[0081] Embodiment 1 as the transport driver 8:

[0082] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com