Material moisture limit-exceeding early warning and control system of roller cut-tobacco drier

A technology of drum silk drying machine and control system, which is applied in the fields of tobacco preparation, food science, application, etc., and can solve problems such as macular smoke, inconvenience, and increased labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

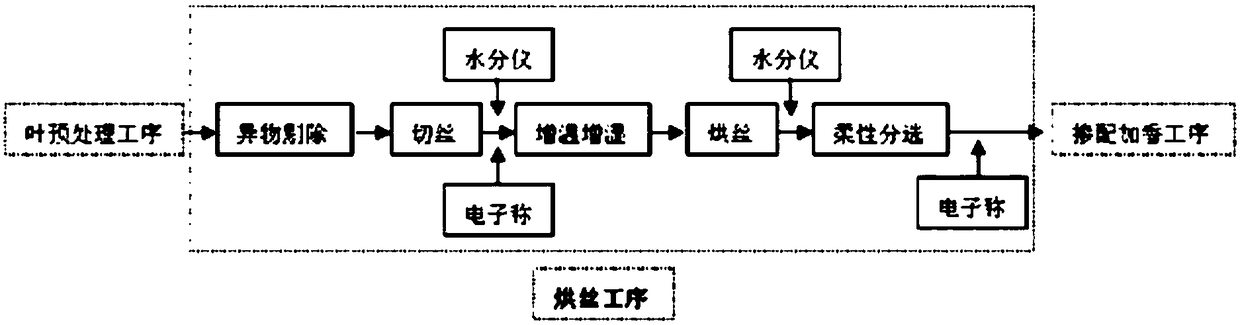

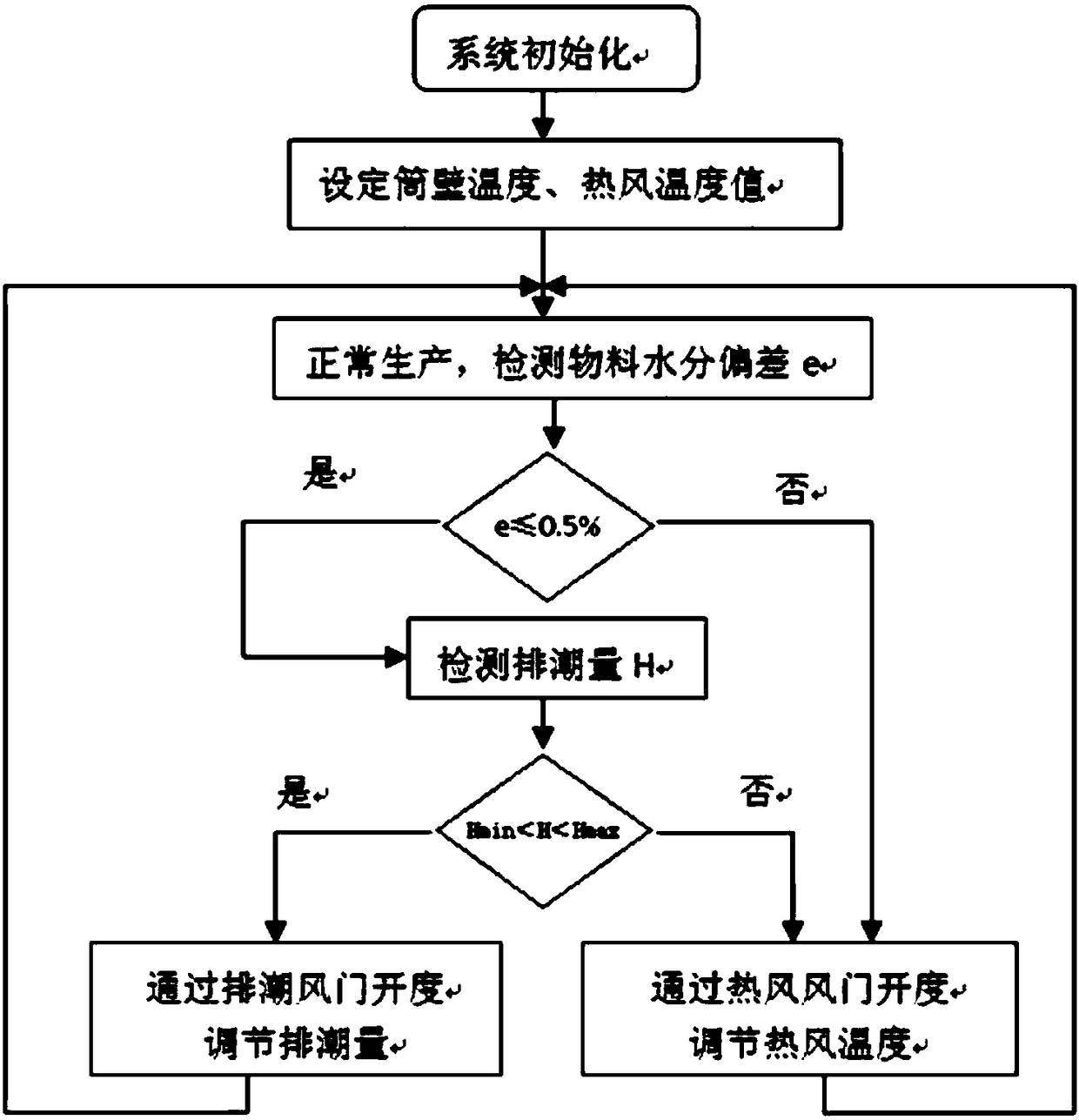

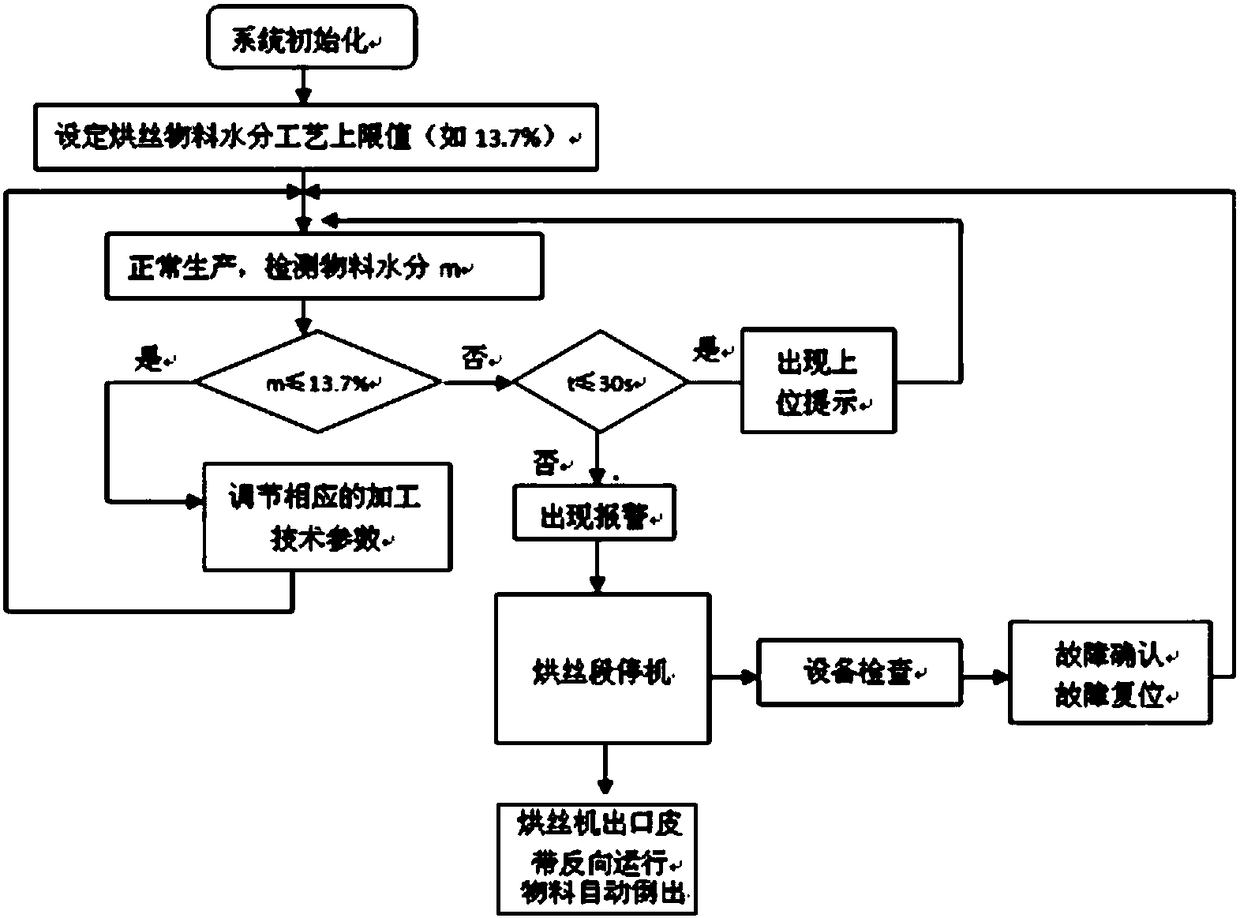

[0031] figure 1 The schematic diagram of the silk drying process is only used to illustrate the shutdown range of this invention and requires a moisture meter after the silk drying machine; figure 2 The silk drying control block diagram is only used to illustrate that the control mode of the drum silk drying machine adopted in this invention is the first control mode; image 3 The material moisture early warning control system of the drum silk drying machine described in the present invention is described as follows:

[0032] In a specific embodiment, the process requirements are: the drum silk drying machine adopts the first control mode in the background technology, the material whose moisture exceeds the upper limit of the process does not exceed 50kg, and the moisture of the output material is 13.4±0.3%.

[0033] Set the excess moisture to the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com