Fire distribution structure of two-cavity direct injection burner

A burner and fire ring technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as difficulty in meeting first-level energy efficiency requirements, the structure of the inner fire cover has not been optimized, and it is difficult to ensure sufficient combustion, etc. Good fire adjustment effect, good air mixing effect and high combustion power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

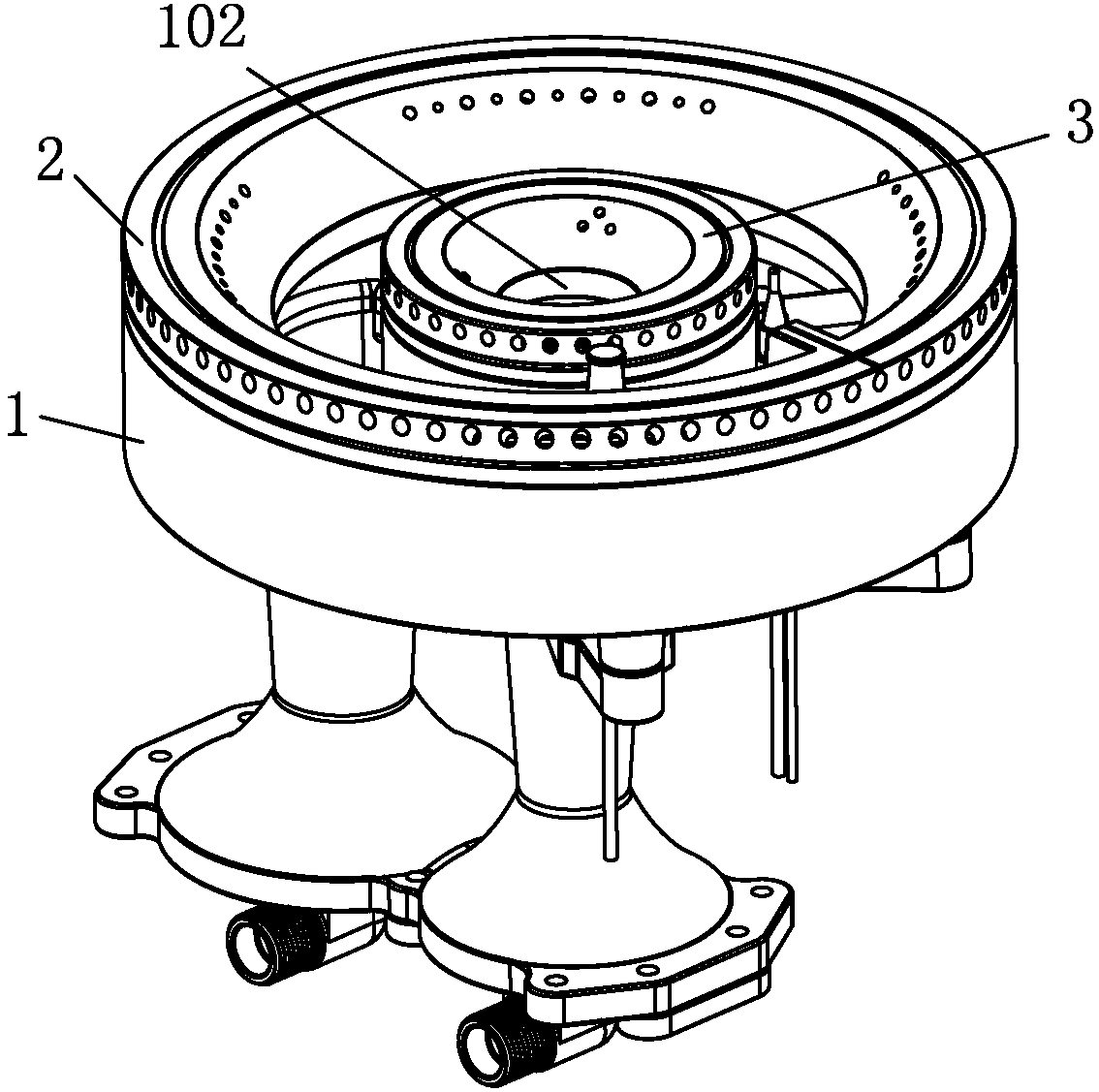

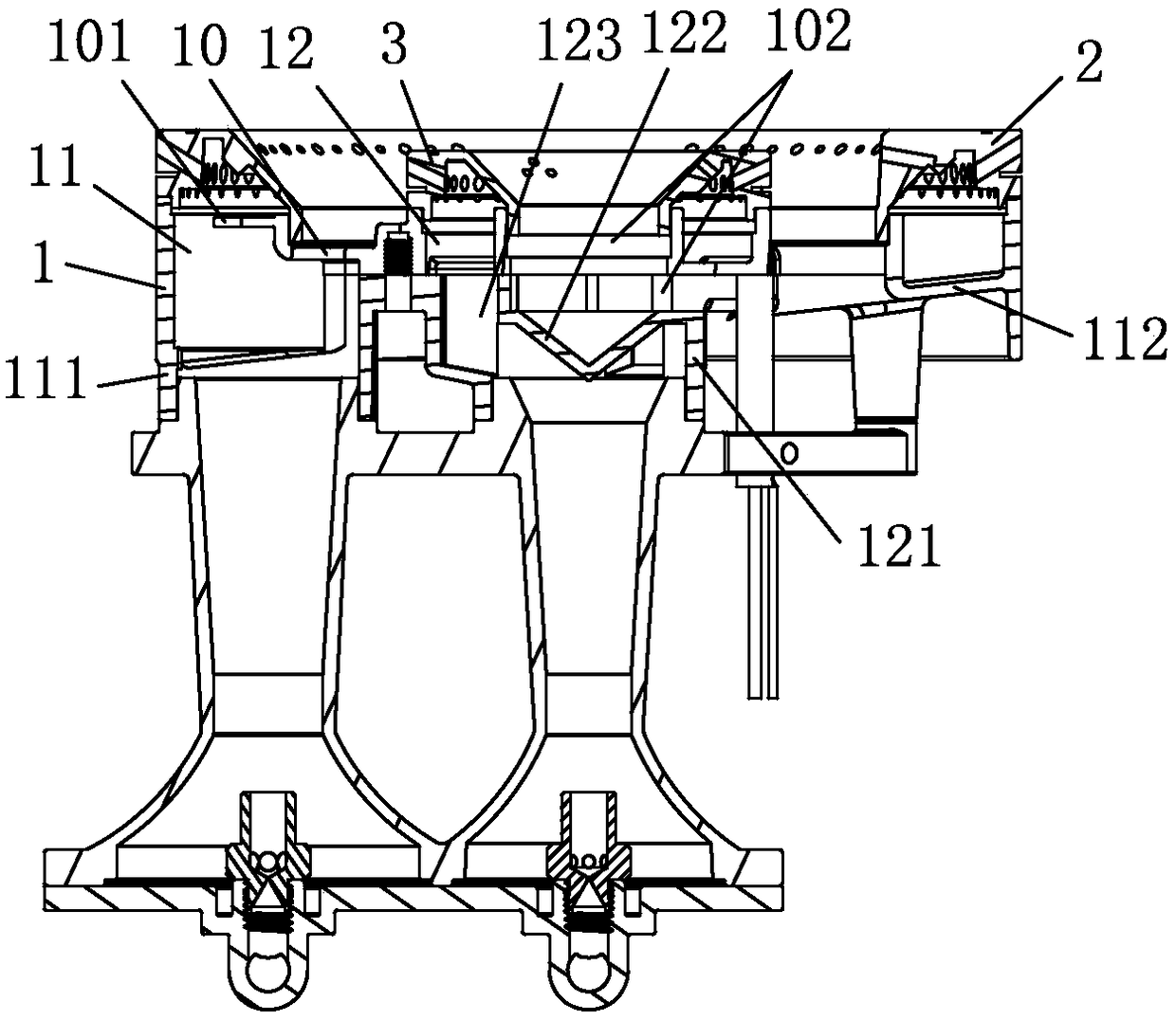

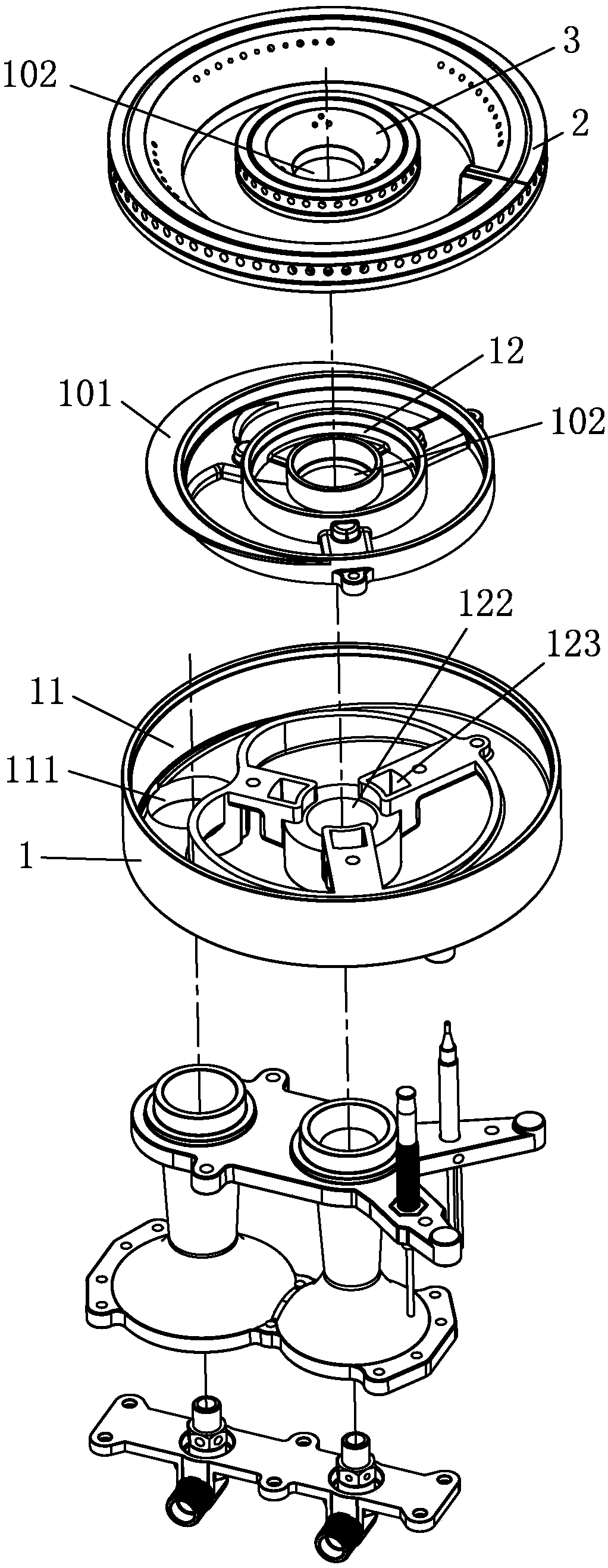

[0021] see Figure 1-4 , the fire distribution structure of the dual-chamber direct injection burner includes a fire cover seat 1 provided with an outer ring fire ring 11 and a central fire ring 12, and the outer ring fire ring 11 and the center fire ring 12 are covered with outer ring fire rings respectively. Cover 2 and center fire cover 3, the bottom of described fire cover seat 1 is provided with outer ring air inlet 111 corresponding to the position of outer ring fire ring 11, and outer ring air inlet 111 communicates with outer ring fire ring 11, and described fire The center of the bottom of the cover seat 1 is provided with a central air inlet 121, and the central air inlet 121 communicates with the central fire ring 12 through several central air inlet passages 123 arranged around it. The bottom of the central air inlet 121 is closed and the inside Corresponding to the junction of the central air inlet 121 and the central air inlet channel 123 on the bottom, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com