Efficient food liquid bag demounting-mounting structure and assembling and demounting-mounting methods

A liquid bag and food technology, which is applied in the direction of article transportation vehicles, transportation and packaging, and vehicles used for freight transportation, etc., and can solve problems such as potential safety hazards and troublesome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

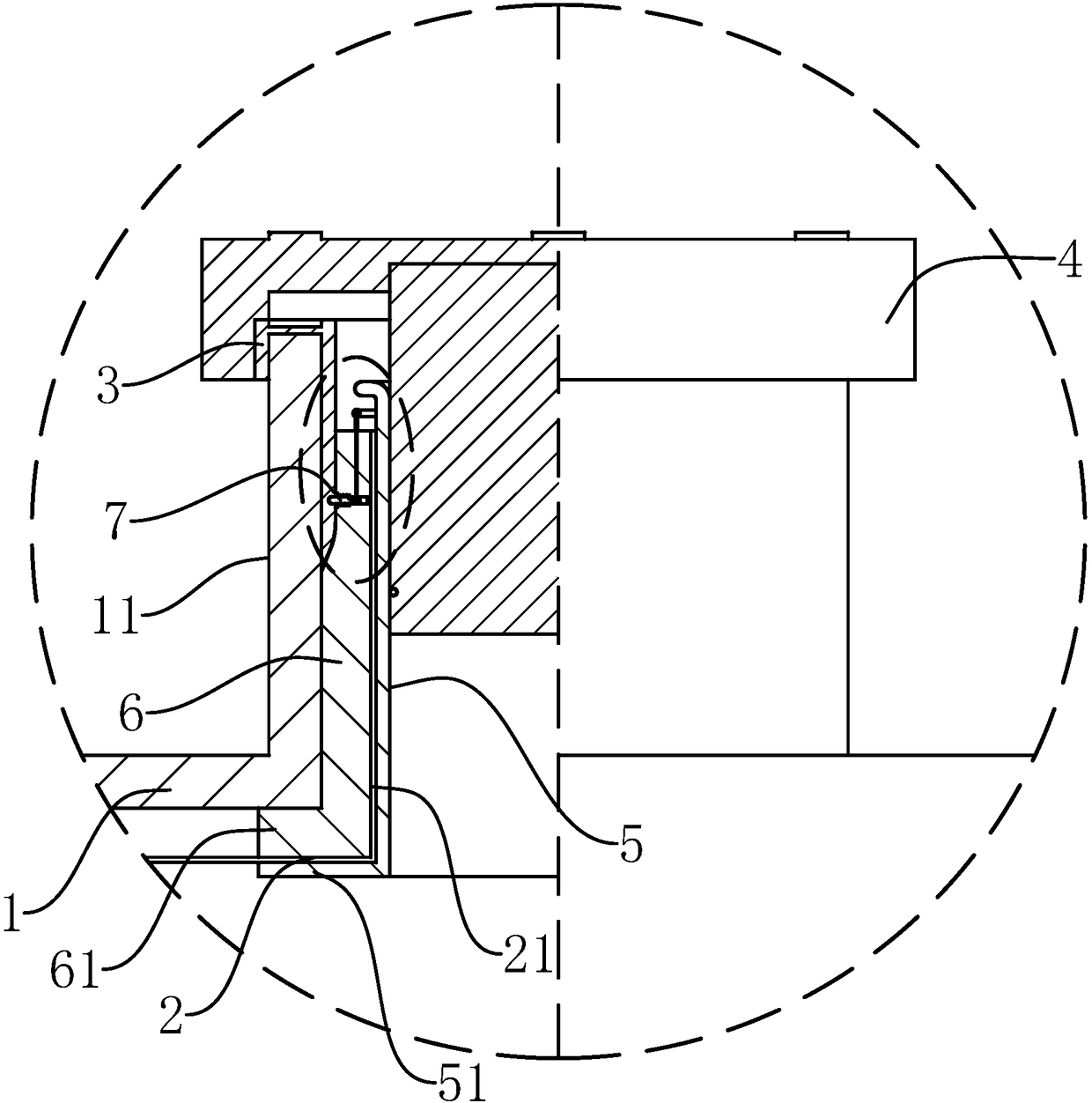

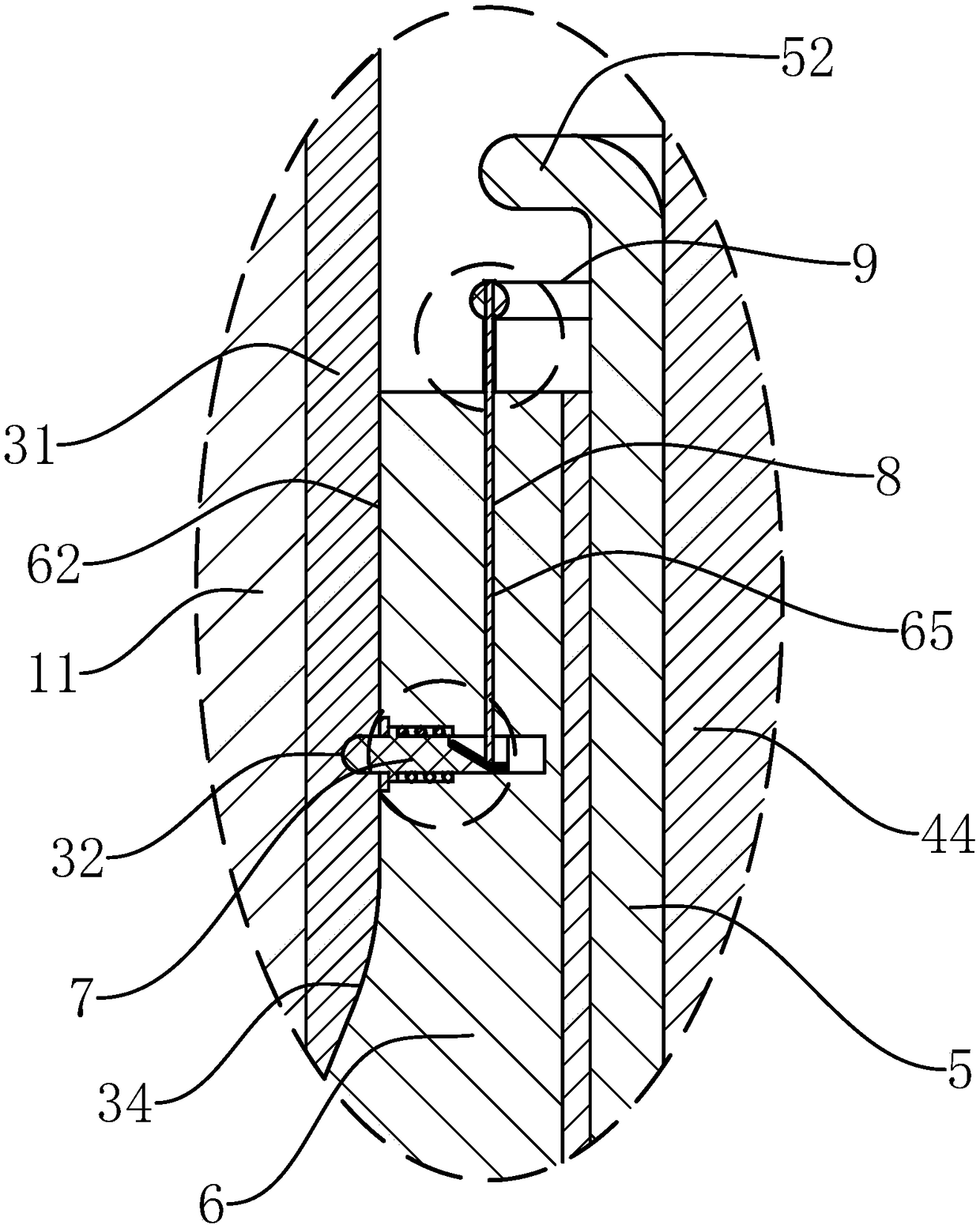

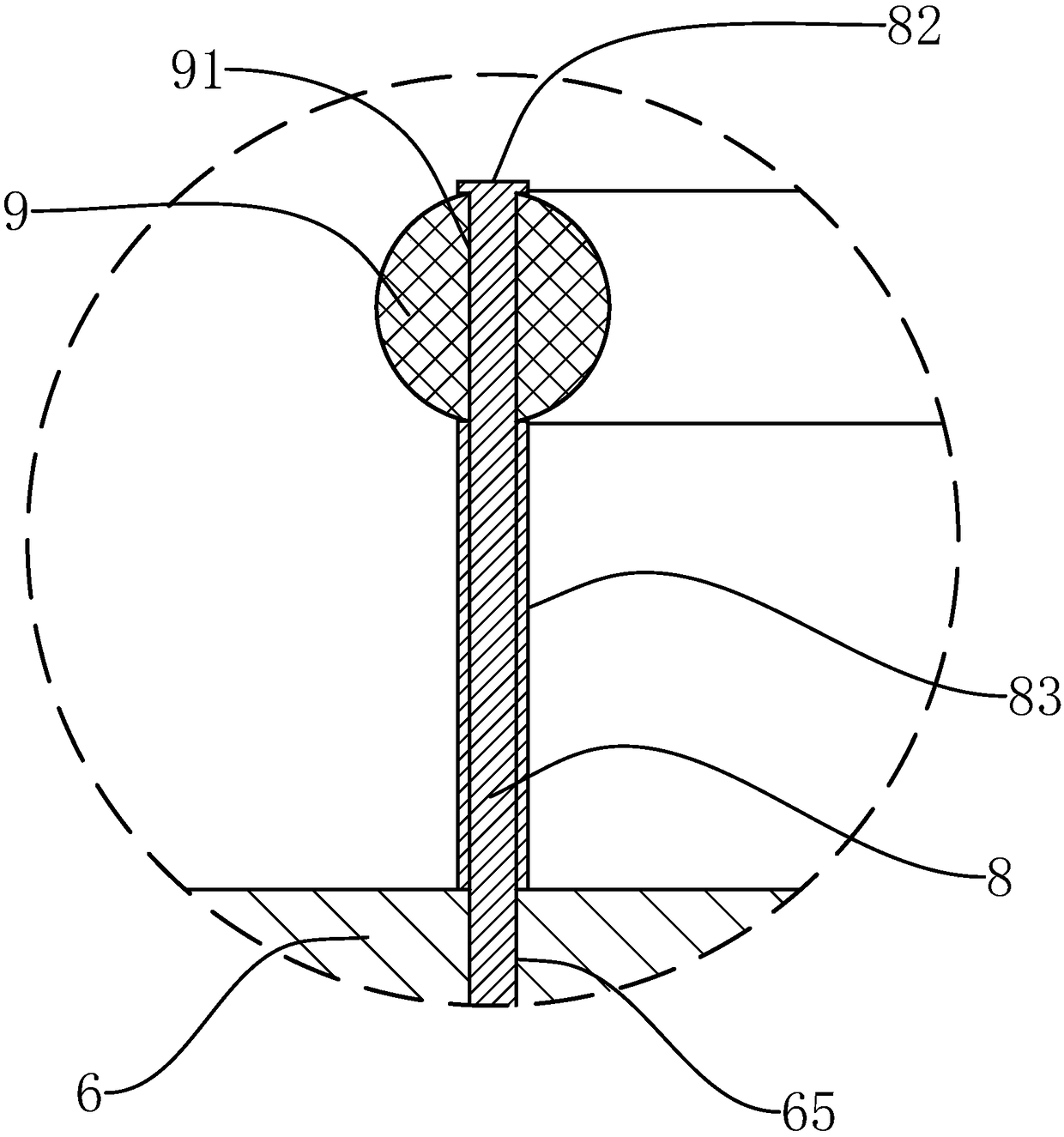

[0053] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0054] Such as Figure 1-8 As shown, a high-efficiency food liquid bag disassembly structure of the present invention includes a compartment 1, the top of the compartment 1 has a bottom end connected with the interior of the compartment 1, and a cylindrical inlet and outlet barrel 11 whose axis is vertically arranged, and also includes a In the compartment 1, there is a sealed flexible liquid bag 2 for placing food. The liquid bag 2 is provided with a circular inlet and outlet, and a cylindrical soft liner 21 is fixed on the inlet and outlet, and also includes a coaxially arranged circular sleeve. The outer connecting sleeve 3 and the inner connecting sleeve 31, and the annular plate-shaped connecting plate 33 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com