esd device structure

An ESD device, P-LDMOS technology, applied in the direction of semiconductor devices, electrical solid state devices, electrical components, etc., can solve problems such as large latchup risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

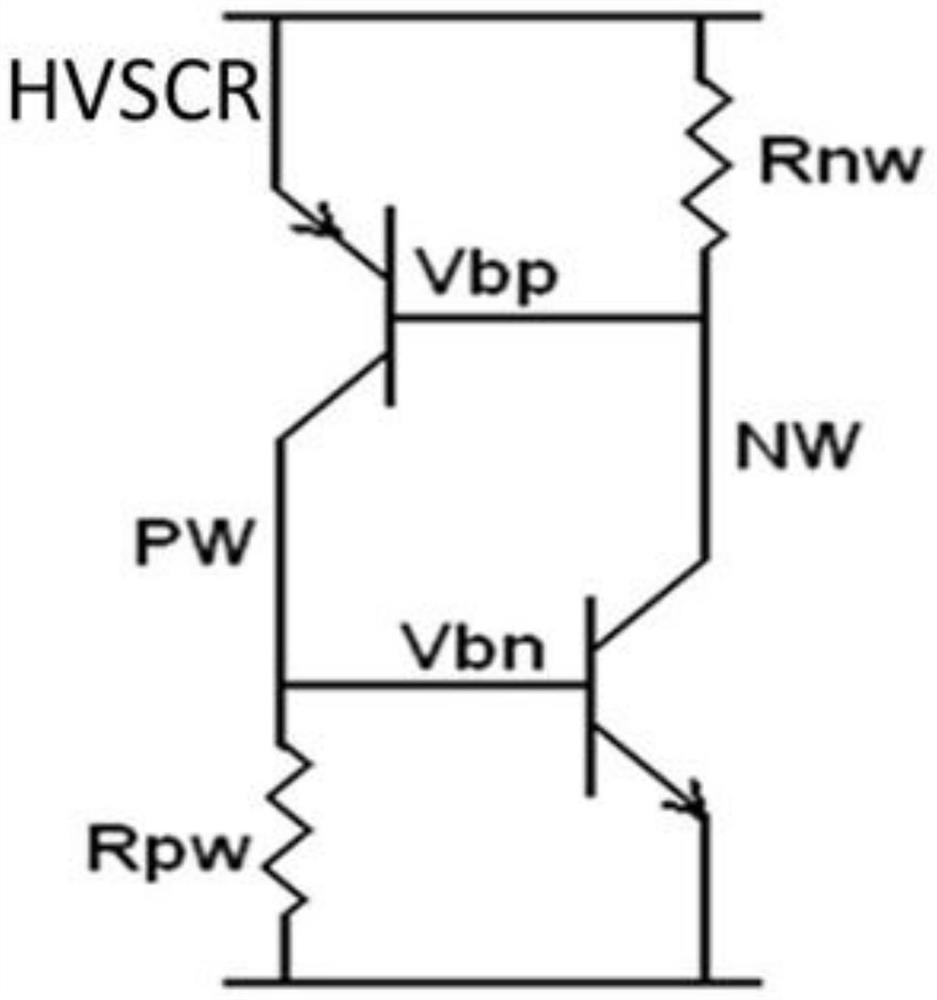

[0043] The ESD device structure of the present invention includes: a first LDMOS, a second LDMOS and a parasitic SCR;

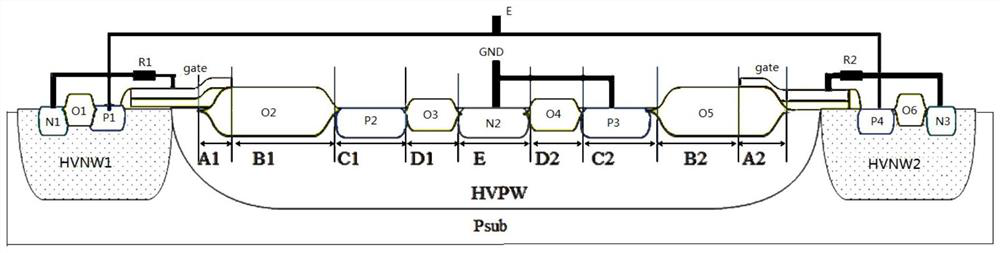

[0044] The first PLDMOS and the second LDMOS are P-LDMOS with the same structure and layout sharing a high-voltage P-well (HVPW), and the high-voltage P-well (HVPW) between the drain of the first P-LDMOS and the drain of the second P-LDMOS The parasitic SCR formed by the N+ region is arranged in the middle, and the first P-LDMOS and the second P-LDMOS form a left-right asymmetric structure centering on the N+ region of the parasitic SCR. The width (A1+B1) of the field oxygen region between the gate and drain of the first LDMOS is greater than the width (A2+B2) of the field oxygen region between the gate and drain of the second LDMOS, so that the structure can be reduced Turn on the voltage.

[0045] Such as image 3 As shown, a specific embodiment of the ESD of the present invention includes: P-type substrate Psub, the first high-voltage N well HVNW1, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com