Ventilation and heat dissipation method for temperature controllers

A technology for ventilation and heat dissipation, temperature controller, applied in the direction of thermal switch parts, electrical components, electric switches, etc., can solve the problems of difficult to replace, difficult to dissipate, damage to the temperature controller, etc., to improve efficiency, avoid easy damage, Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

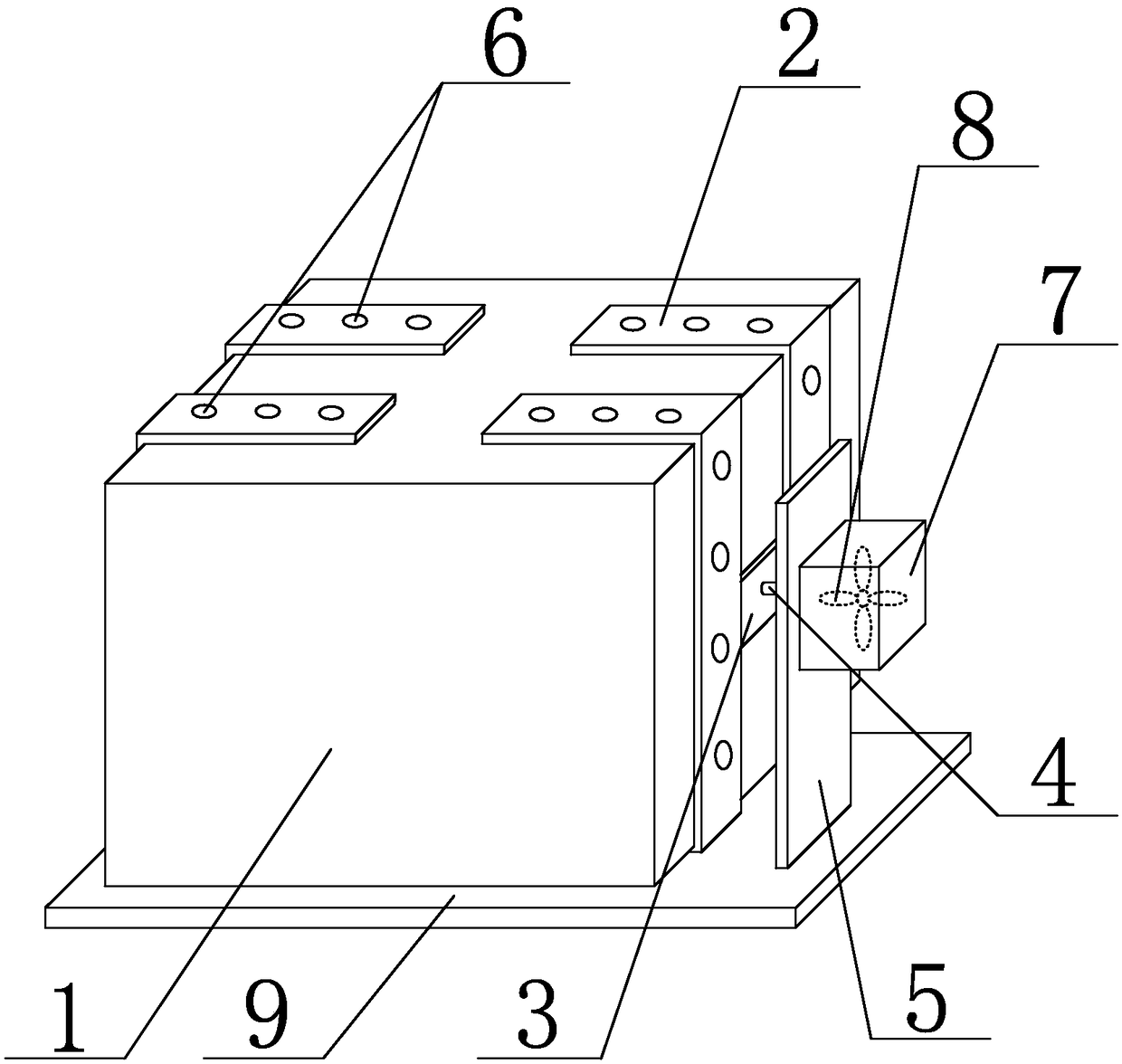

[0021] Such as figure 1 As shown, a method for ventilation and heat dissipation of a temperature controller in the present invention includes the following steps: 1) installing the temperature controller inside the electrical appliance, the temperature controller includes a temperature controller body 1, the left and right sides of the temperature controller body 1 There are two fixed groove plates 2 arranged in parallel at each end, the end of the temperature controller body 1 is embedded in the groove of the fixed groove plate 2, the inner wall of the fixed groove plate 2 and the upper surface of the temperature controller body 1 Slidingly connected with the lower surface, two fixed groove plates 2 arranged in parallel can move relatively along the surface of the temperature controller body 1 and the distance between them can be adjusted; the two fixed groove plates 2 are stretched The plate 3 is connected, the telescopic plate 3 is vertically connected with a connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com