Liquid vaporizing device and semiconductor processing system using same

A vaporization device, liquid technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve problems such as prolonged vaporization time and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In this specification and the following patent claims, unless the context requires otherwise, the word "comprise" and variants such as "comprising" or "comprising" will be understood as implying that the integer group or step is included, but Any other integer or group of integers is not excluded.

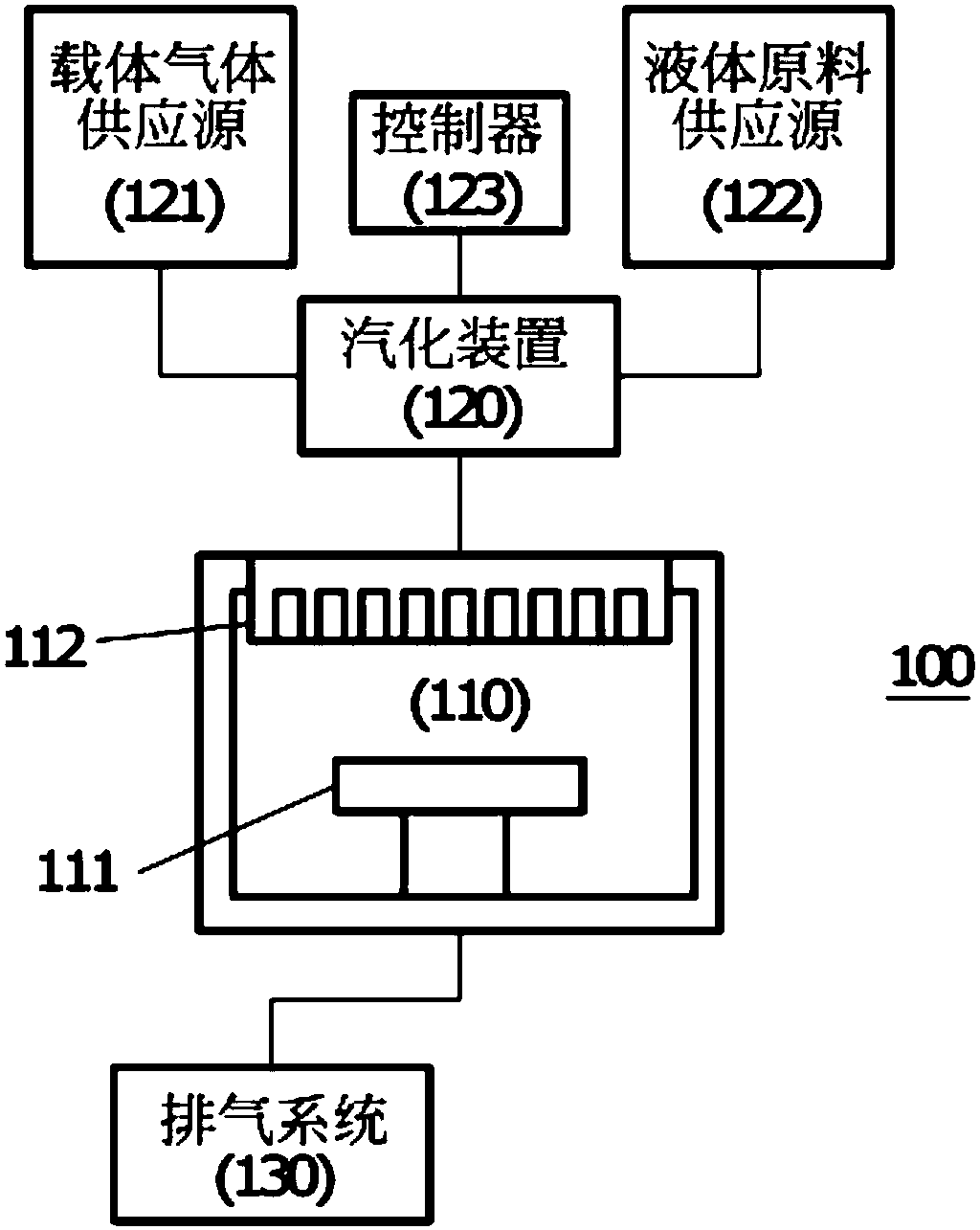

[0030] figure 1 An embodiment 100 of a semiconductor processing system of the present invention is shown. The system 100 includes a reaction chamber 110 , a vaporization device 120 and an exhaust system 130 . In general, a typical reaction chamber 110 mainly has a support structure 111 for supporting wafers, a shower device 112 for supplying reaction gases, and at least one exhaust channel (not shown) for exhausting process exhaust gases. . The reaction chamber 110 is substantially cylindrical, and the support structure 111 has a base for horizontally supporting the wafer and a support member for supporting the base. The susceptor may embed a heater for heating the susce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com