A kind of tc4 titanium alloy large-scale slab and its preparation method and application

A large-scale, titanium alloy technology, applied in the field of TC4 titanium alloy large-scale slab and its preparation, can solve the problems of long production process, short process and high production cost, and meet the needs of large-scale development, mixing and pressing. The effect of uniform control and accurate weighing of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

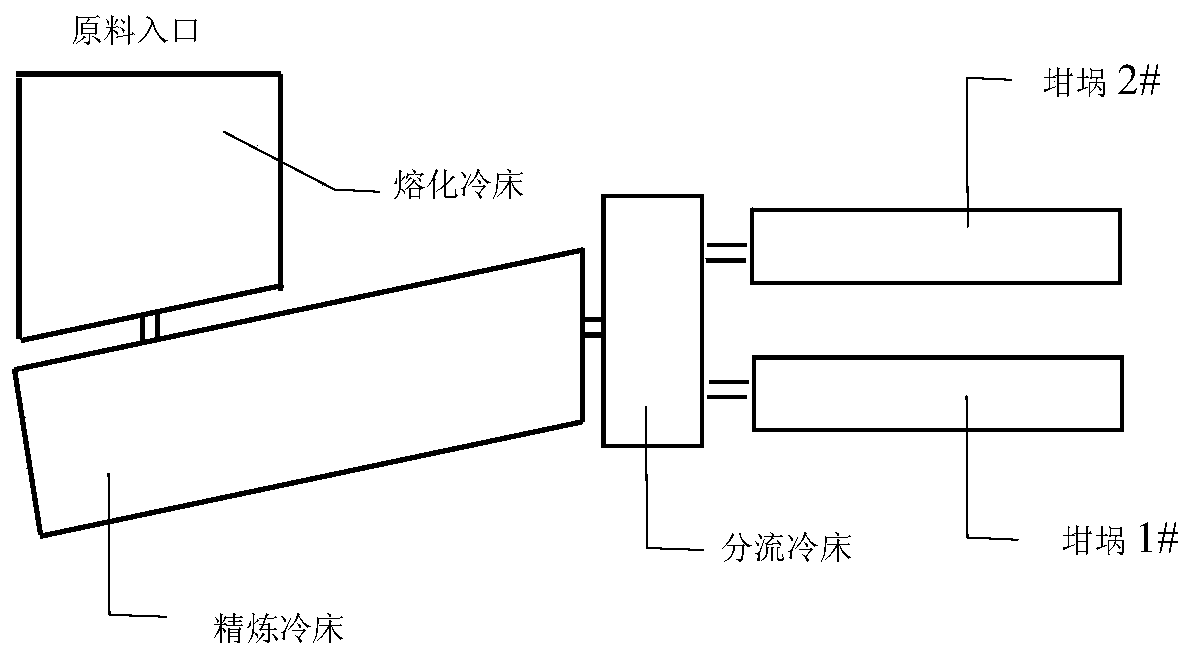

Method used

Image

Examples

Embodiment 15

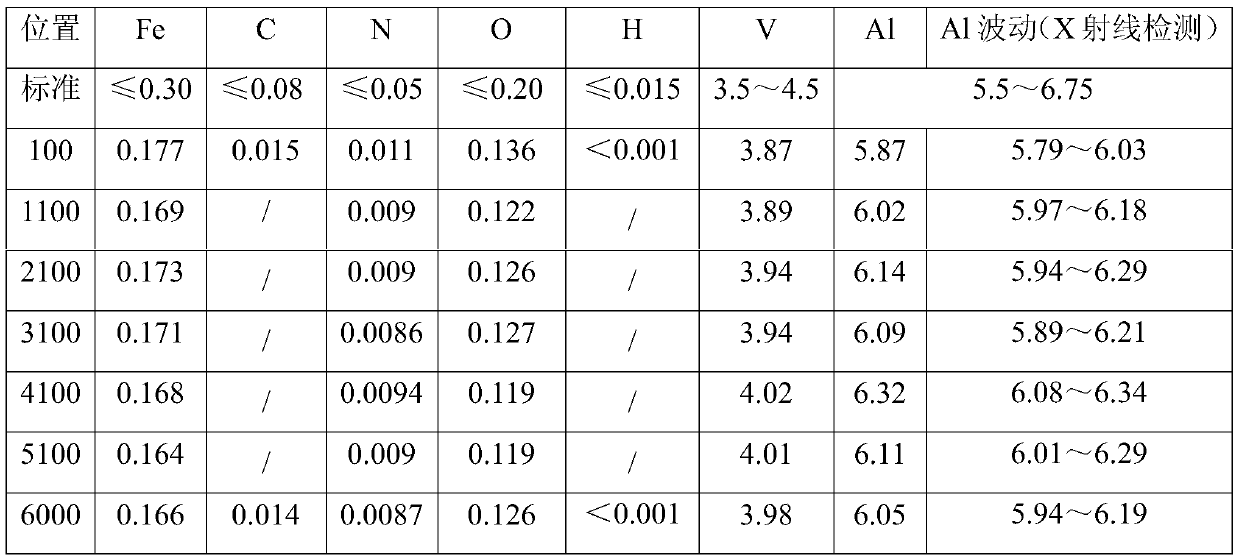

[0052] Example 1 Preparation of 5 tons of TC4 titanium alloy large-scale slabs

[0053] (1) Calculation of ingredients:

[0054] ①Use sponge titanium and intermediate alloy to combine, and the basis of alloying elements is calculated as Al=8.0%, V=3.9%, Fe=0.18%, O=0.12%. According to the empirical value of Al burning loss, the target Al content of the smelted slab is 6.2%.

[0055] ②Calculate the total addition amount of various raw materials and the addition amount of a single electrode according to the basic composition of alloying elements. Among them, grade 0 sponge titanium 5340Kg, AlV55 alloy 414Kg, aluminum bean 318Kg, iron powder 10.9Kg, titanium dioxide 9.0Kg, a total of 6092Kg. Press 140 pieces, the weight of a single piece is 43.5Kg, including 38.14Kg of grade 0 sponge titanium, 2.96Kg of AlV55 alloy, 2.27Kg of aluminum beans, 0.08Kg of iron powder, and 0.06Kg of titanium dioxide.

[0056] (2) Pressing electrode: The sponge titanium is sorted to remove the defec...

Embodiment 27

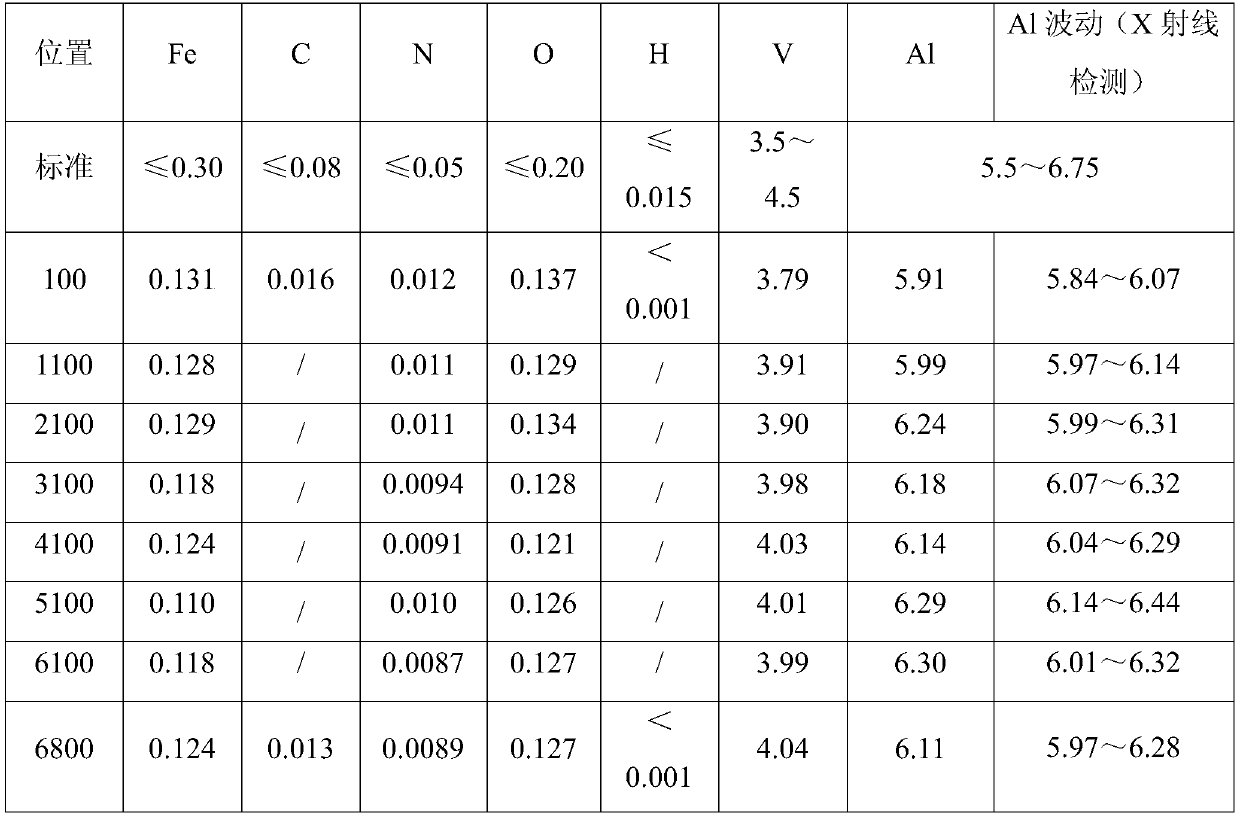

[0081] Example 2 Preparation of 7 tons of TC4 titanium alloy large-scale slabs

[0082] (1) Calculation of ingredients:

[0083] ①Use sponge titanium and intermediate alloy to combine, and the basis of alloying elements is calculated as Al=8.0%, V=4.0%, Fe=0.12%, O=0.12%. According to the empirical value of Al burning loss, the target Al content of the smelted slab is 6.2%.

[0084]②Calculate the total addition amount of various raw materials and the addition amount of a single electrode according to the basic composition of alloying elements. Among them, grade 0 sponge titanium 7160Kg, AlV55 alloy 554Kg, aluminum bean 426Kg, iron powder 9.8Kg, titanium dioxide 12.2Kg, a total of 8160Kg. Press 182 pieces, the weight of a single piece is 45Kg, including 39.3Kg of grade 0 sponge titanium, 3.04Kg of AlV55 alloy, 2.34Kg of aluminum beans, 0.05Kg of iron powder, and 0.07Kg of titanium dioxide.

[0085] (2) Pressing electrode: The sponge titanium is sorted to remove the defective...

Embodiment 3

[0109] Example 3 Preparation of 6 tons of TC4 titanium alloy large-scale slabs

[0110] (1) Calculation of ingredients:

[0111] ①Use sponge titanium and intermediate alloy to combine, and the basis of batching alloy elements is calculated as Al=8.5%, V=4.0%, Fe=0.12%, O=0.12%. According to the empirical value of Al burning loss, the target Al content of the smelted slab is 6.2%.

[0112] ②Calculate the total addition amount of various raw materials and the addition amount of a single electrode according to the basic composition of alloying elements. Among them, grade 0 sponge titanium 12170Kg, AlV55 alloy 943Kg, aluminum bean 725Kg, iron powder 16.2Kg, titanium dioxide 20.8Kg, a total of 13875Kg. Pressing 308 pieces, the weight of a single piece is 45Kg, including 39.55Kg of grade 0 sponge titanium, 3.06Kg of AlV55 alloy, 2.35Kg of aluminum beans, 0.05Kg of iron powder, and 0.07Kg of titanium dioxide.

[0113] (2) Pressing electrode: The sponge titanium is sorted to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com