Combine-harvester all-round threshing and separating device

A combine harvester, threshing separation technology, applied in the direction of threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of low efficiency of threshing and separation operations, no threshing operations, etc. Consumption, improve the effect of separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

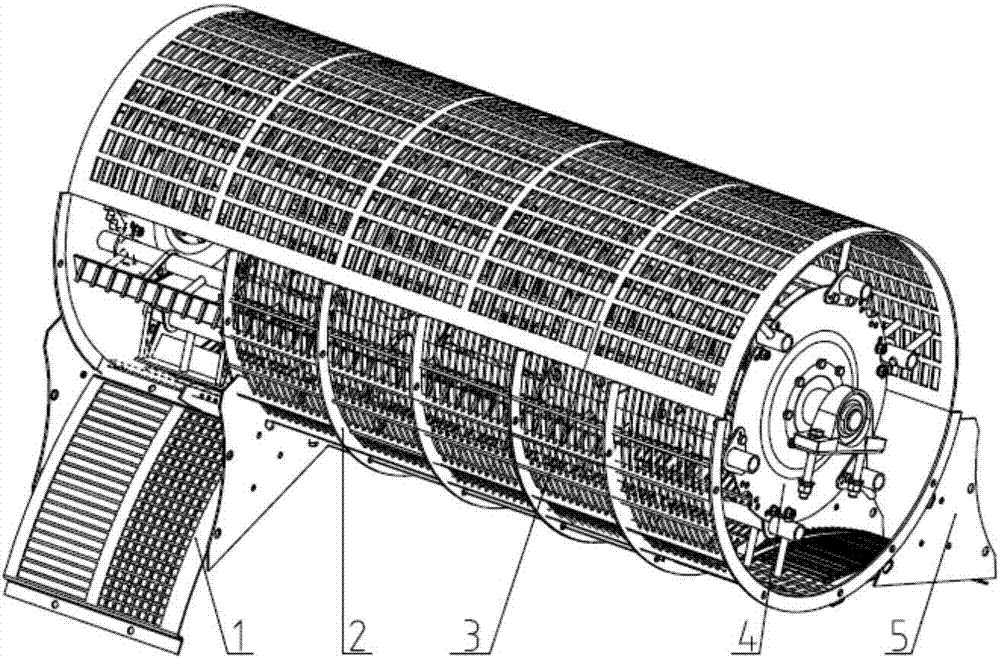

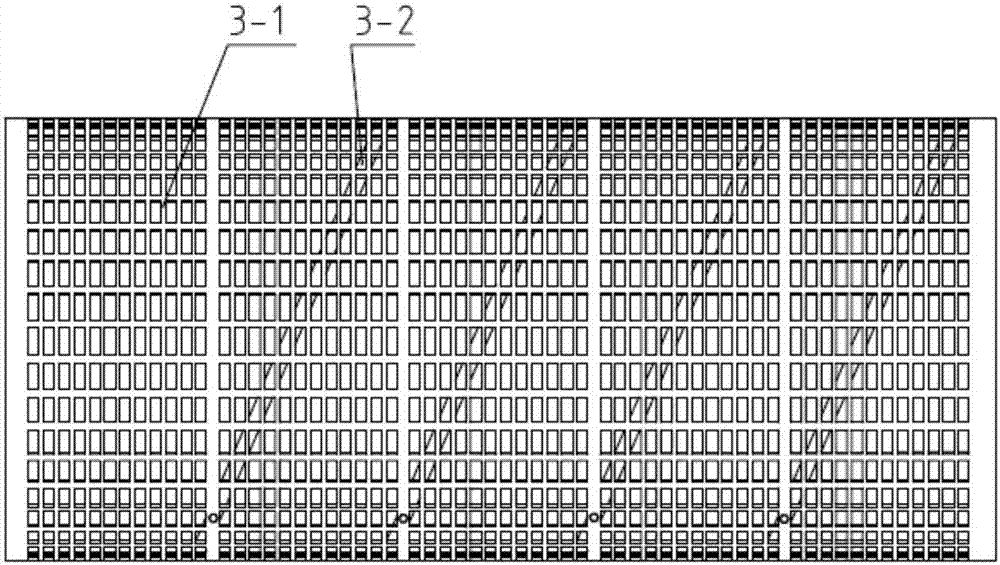

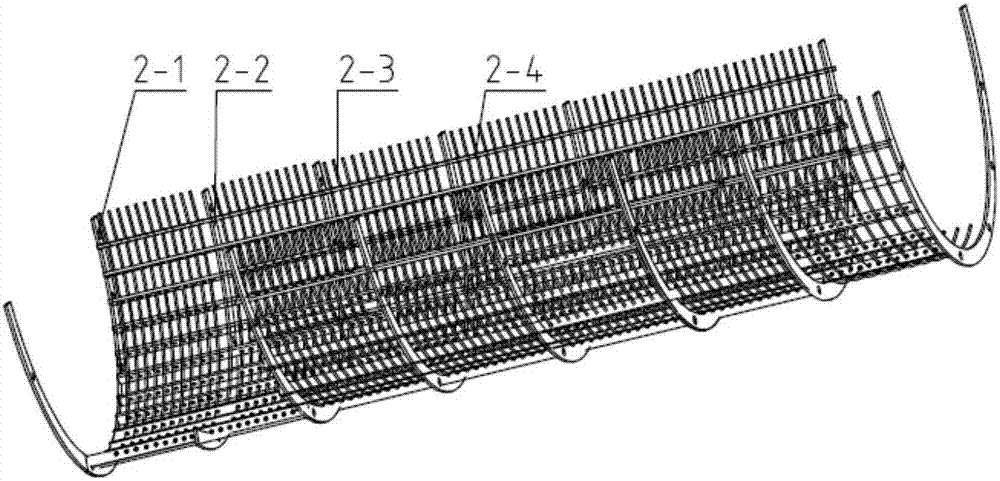

[0021] The basic structure of the combine harvester full-circle threshing and separating device of the present embodiment is as follows: figure 1 As shown, it includes a threshing drum 4 located in the upper concave screen 3 and the lower concave screen 2, and the two ends of the lower concave screen 2 have an inlet 1 and an outlet 2 respectively. The specific structure of the upper concave screen 3 is as follows: figure 2 As shown, it consists of a circular arc sieve plate 3-1 with sieve holes and spiral guide plates 3-2 fixed in the sieve plate 3-1 and distributed at intervals. Lower concave plate sieve 2 such as image 3 As shown, the circular arc plates 2-1 and 2-2 distributed in axial intervals, the circular arc screen bar 2-3 spaced between adjacent circular arc plates, and the circular arc plate and the circular arc screen bar 2- 3 The fixed circumferential intervals are composed of axially extending horizontal plates 2-4 to form sieve holes. The two ends of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com