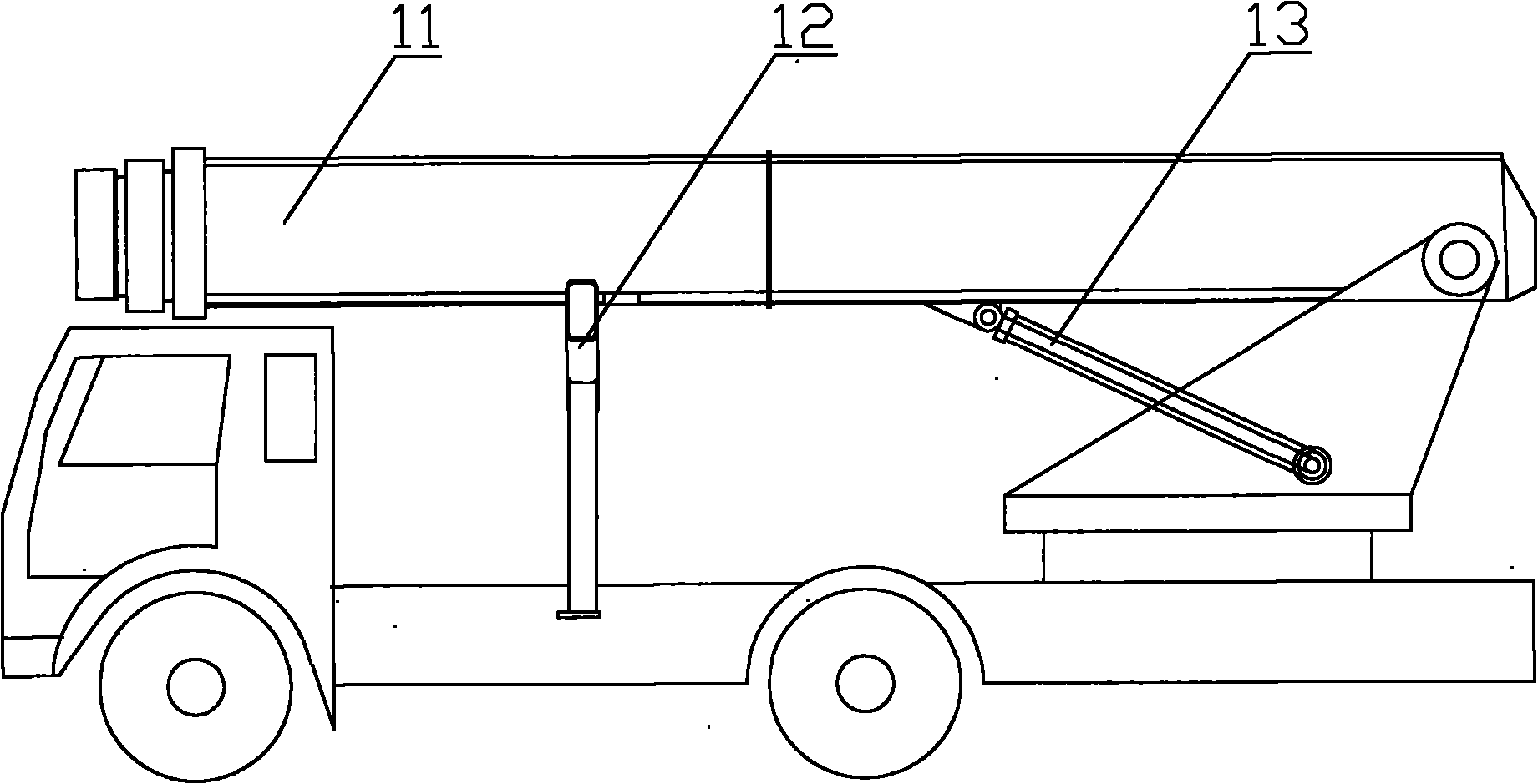

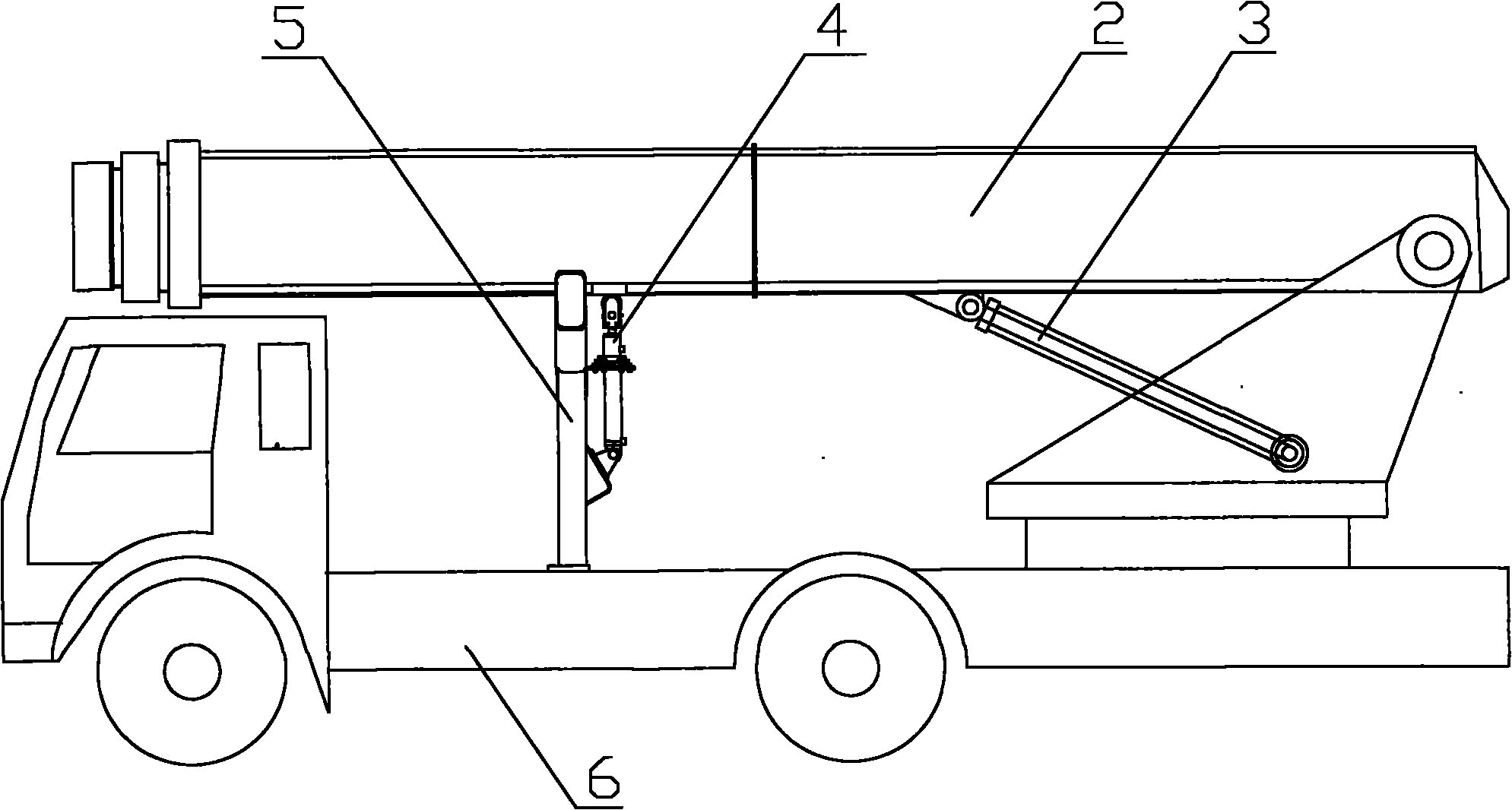

Construction vehicle and arm support supporting device thereof

A technology for supporting devices and engineering vehicles, applied in cranes and other directions, can solve the problems affecting the performance parameters of engineering vehicles, difficult arrangement of luffing mechanisms, and increased overall weight, so as to improve the luffing operation capacity, improve the arrangability, and improve the reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

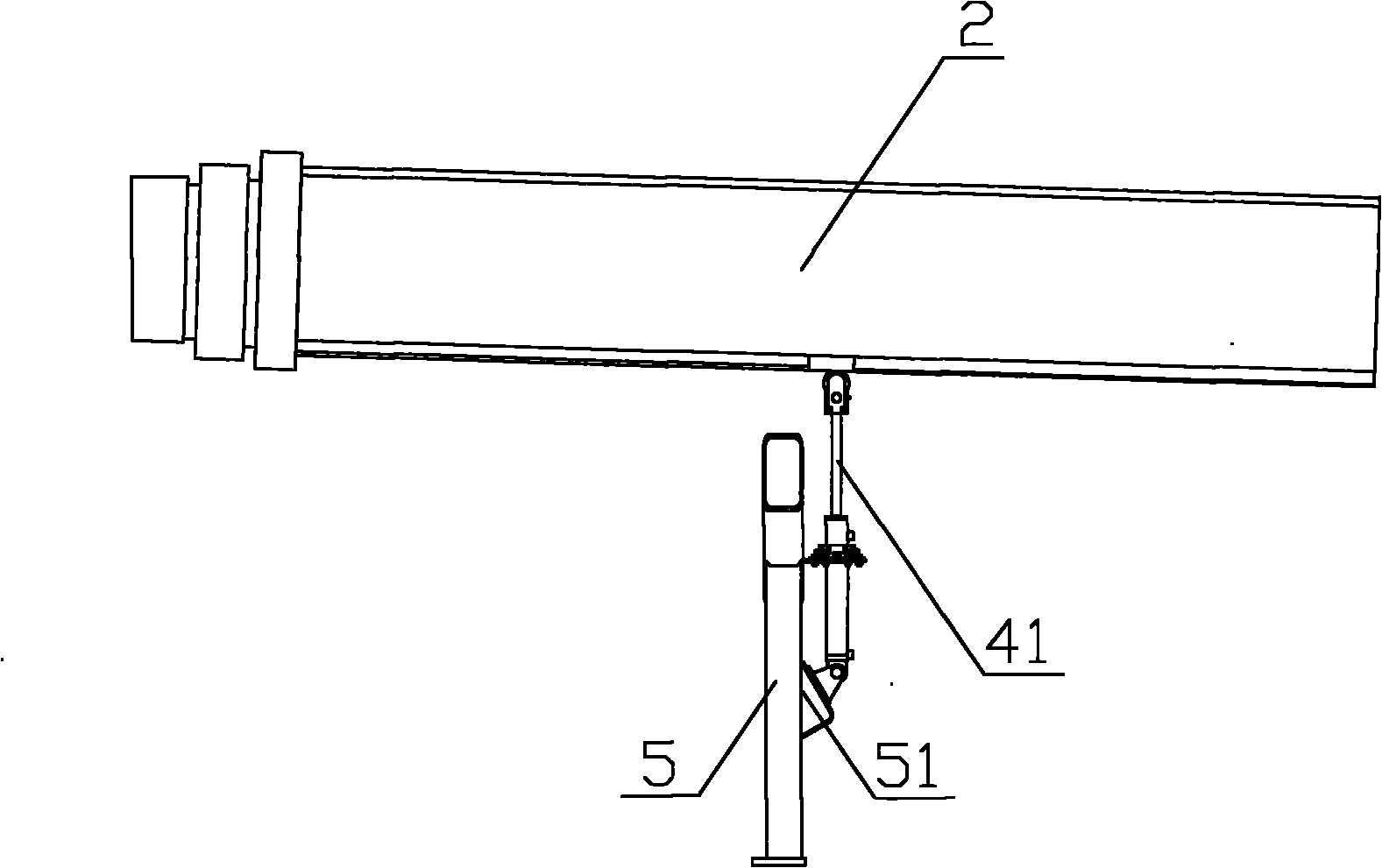

[0032] The core of the present invention is to provide a jib support device for engineering vehicles. The jib support device increases the luffing force of the luffing mechanism without increasing the size of the luffing oil cylinder, and satisfies the needs of engineering vehicles. Luffing job requirements. Another core of the present invention is to provide an engineering vehicle comprising the above-mentioned jib support device, and the reliability of the engineering vehicle is improved.

[0033] The orientation words involved in this article, such as upper, front, rear, left, and right, are defined based on the direction of the construction vehicle and the position of the operator of the engineering vehicle. It should be understood that the orientation words used in this article The scope of protection of this patent should not be limited.

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com