Concentrated salt waste water atomizing concentration cyclic crystallization zero discharge system and process

A zero-discharge, waste water technology, applied in dewatering/drying/concentrating sludge treatment, multi-stage water treatment, water/sewage treatment, etc. Simple, flexible and reliable, with a large range of operation flexibility, and the effect of ensuring operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

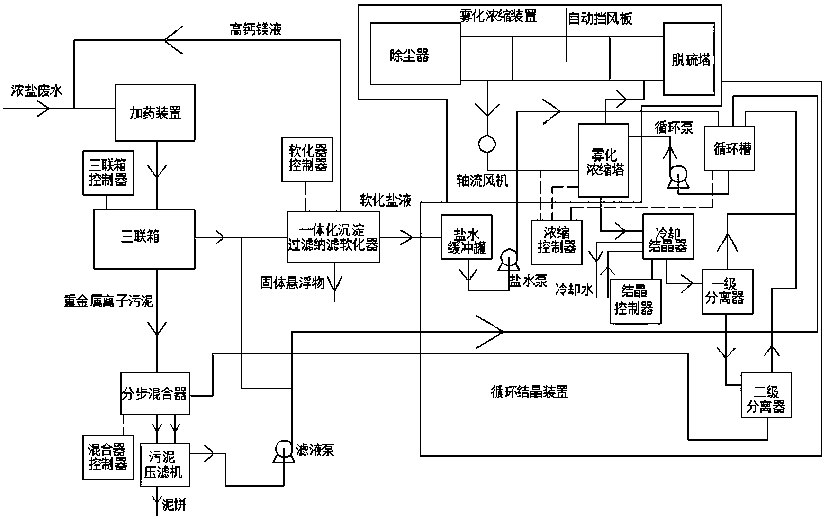

[0032] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises a triple box, the triple box is connected with an integrated precipitation filtration nanofiltration softener, the integrated precipitation filtration nanofiltration softener is connected with the atomization concentration tower of the atomization concentration device through a circulation tank, and the atomization concentration tower is connected with the circulation crystallization The cooling crystallizer of the device is connected, the triple box and the cooling crystallizer are respectively connected with a step mixer, and the step mixer is connected with a sludge filter press. The front end of the triple box is connected with a dosing device, the integrated precipitation filtration nanofiltration softener is connected with the circulation tank through a brine buffer tank and a brine pump, a circulation pump is connected between the circulation tank and the atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com