Seismic pendulum type conveying mechanism

A conveying mechanism and conveying trough technology, which is applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve problems such as waste, poor quality of pulp, and disorderly orientation of oranges, so as to achieve convenient operation, realize directional conveying, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

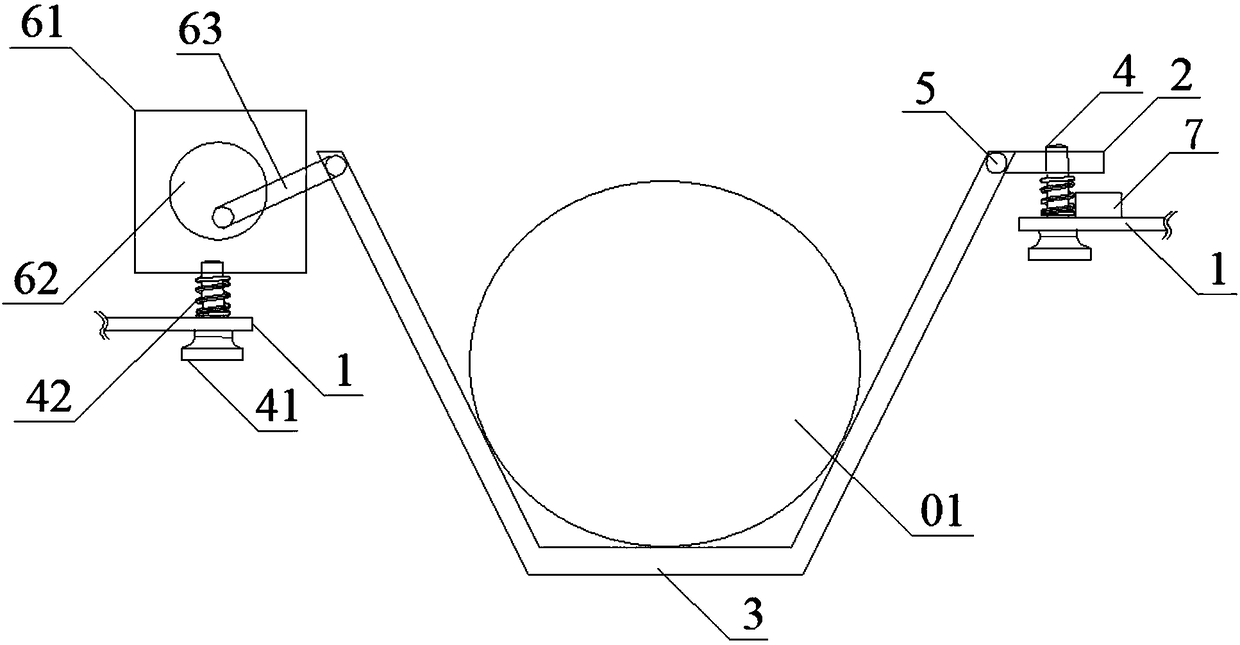

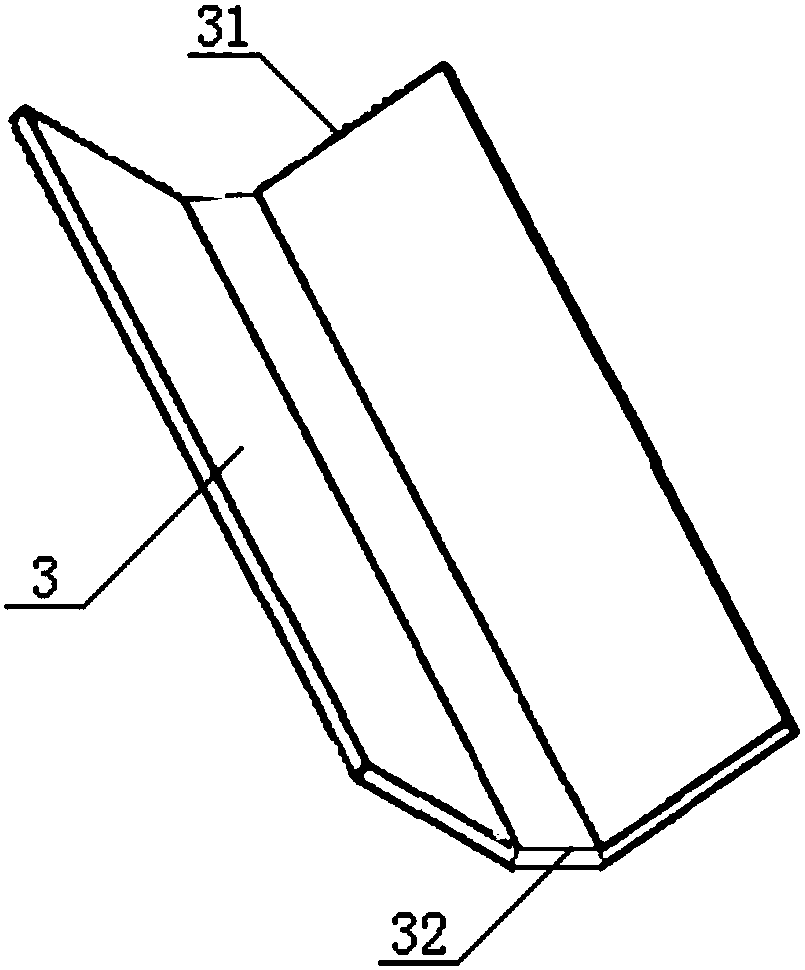

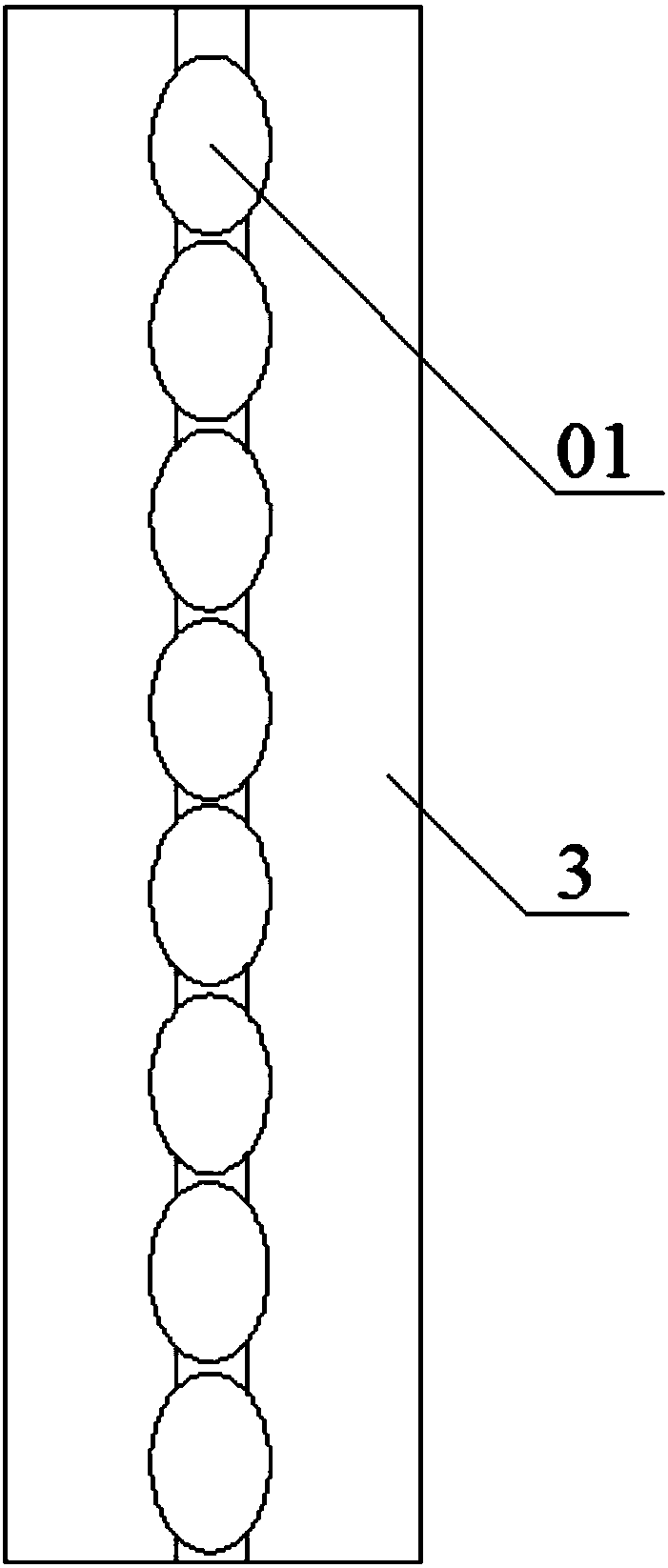

[0026] see Figure 1~4 , a pendulum-type conveying mechanism for conveying oblate or pear-shaped articles 01, the conveying mechanism includes a frame 1, a fixed seat 2, a conveying trough 3, an elastic connection mechanism 4, and is used to drive the conveying trough 3 around The swinging drive mechanism is used to drive the vibrator 7 of the elastic connection mechanism 4 to vibrate. One side of the conveying trough 3 is connected to the fixed base 2 through the rotating shaft 5, and the other side is hinged to the driving mechanism. Both the fixed seat 2 and the driving mechanism are connected with the frame 1 through the elastic connecting mechanism 4 . The delivery tank 3 includes an inlet 31 and an outlet 32 , and is inclined from the inlet 31 to the outlet 32 . The size of the conveyor trough 3 and the item 1 it transports must meet the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com