Elastic fire hose

A technology for fire hoses and hoses, applied in fire rescue, etc., can solve the problems of cumbersome and time-consuming operations, wear and damage of the hose body, and poor elastic effect of materials, etc., to achieve good wear resistance, not easy to leak, and good The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

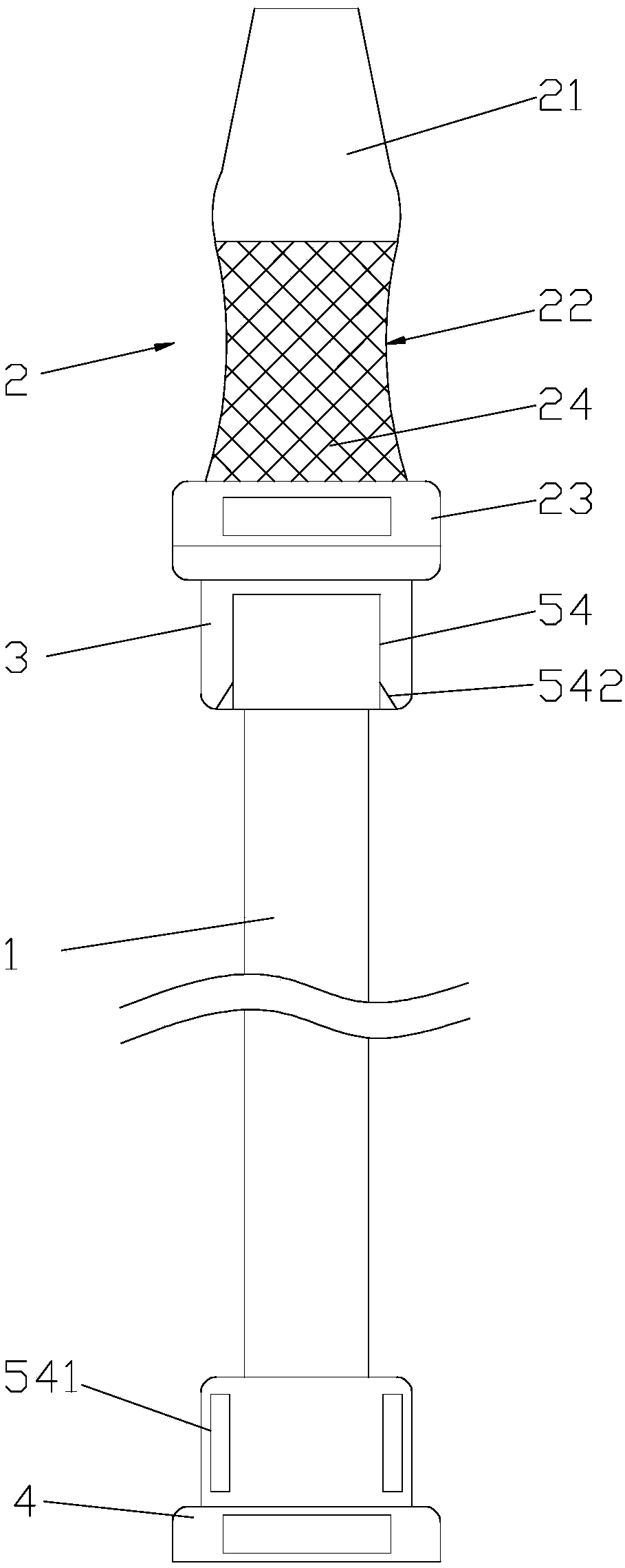

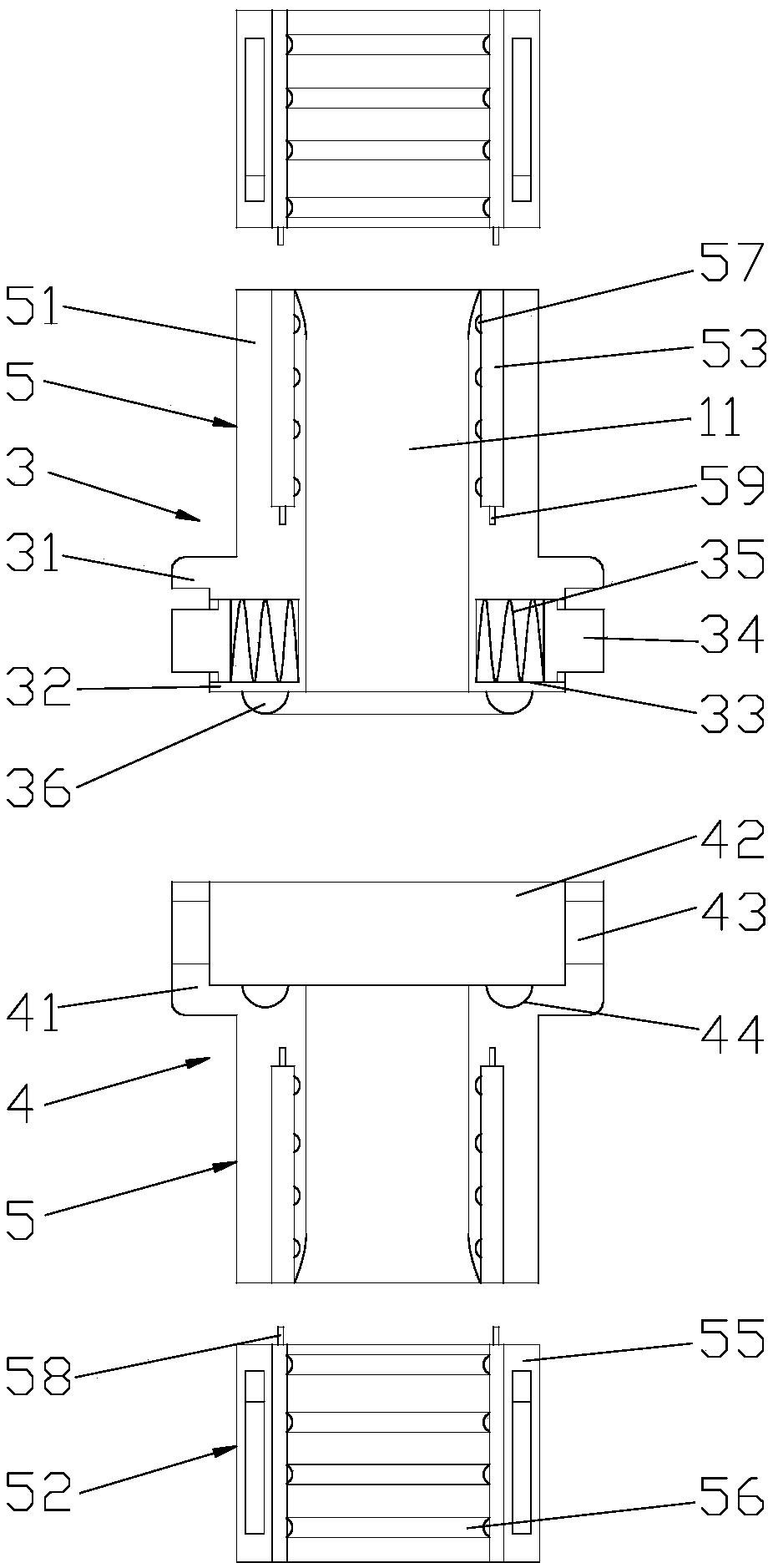

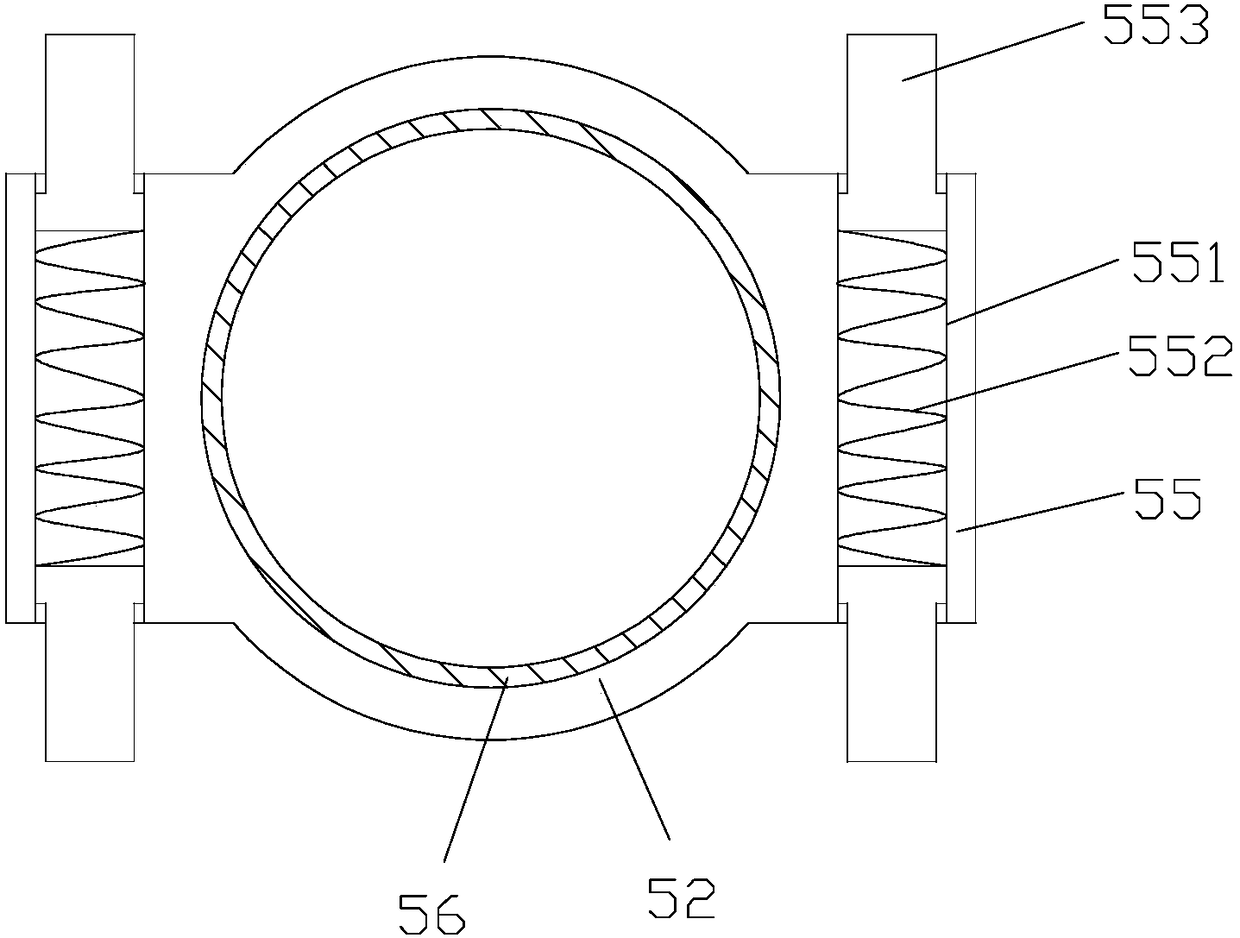

[0019] Such as Figure 1 to Figure 4 As shown, a flexible fire hose includes a hose body 1 and a water gun body 2, the two ends of the hose body 1 are respectively equipped with a first joint 3 and a second joint 4, and the water gun body 2 and the water gun body 2 are connected to each other. The first joint 3 is assembled and connected, the first joint 3 and the second joint 4 are provided with a channel 11, the first joint 3 is provided with an assembly part 31, and the second joint 4 is provided with a first installation part 41, The water gun body 2 includes a spray head 21, a handle portion 22 and a second mounting portion 23, the first mounting portion 41 is the same as the second mounting portion 23, the outer wall of the handle portion 22 is concave, and the outer wall of the handle portion 22 is Anti-slip lines 24 are distributed, and the nozzle 21 gradually shrinks from bottom to top, which can increase the friction between the palm and the palm, making it difficult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com