Damage imaging system based on Lamb waves

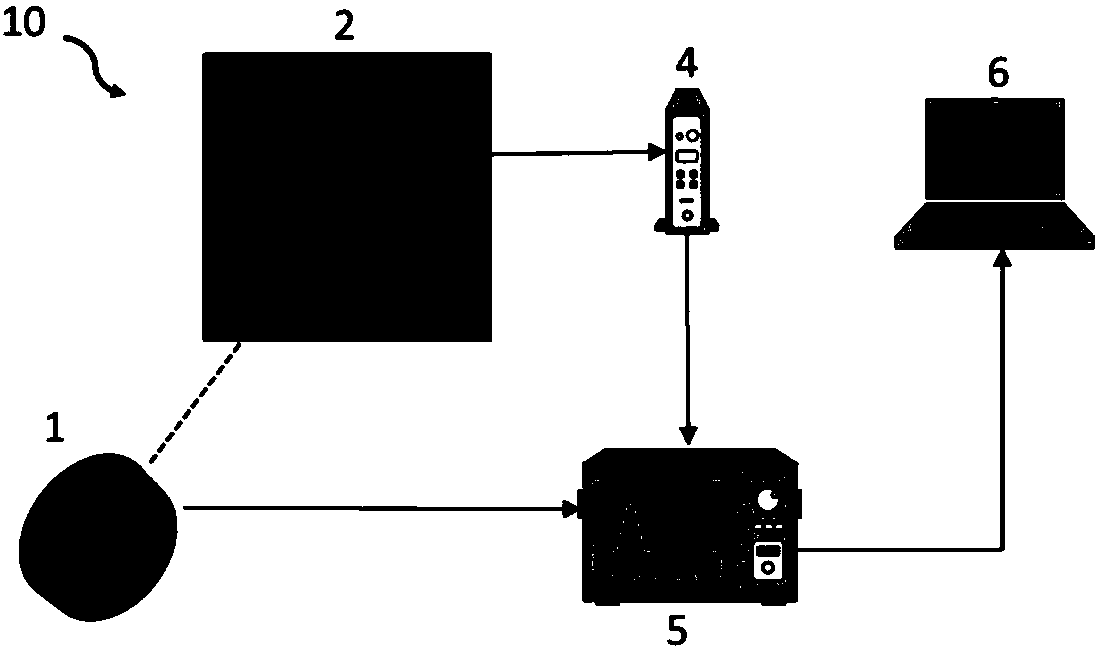

An imaging method, fast technology, applied in processing detection response signals, using acoustic wave emission technology for material analysis, instruments, etc., can solve problems such as inability to detect damage, and achieve the effect of rapid identification and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

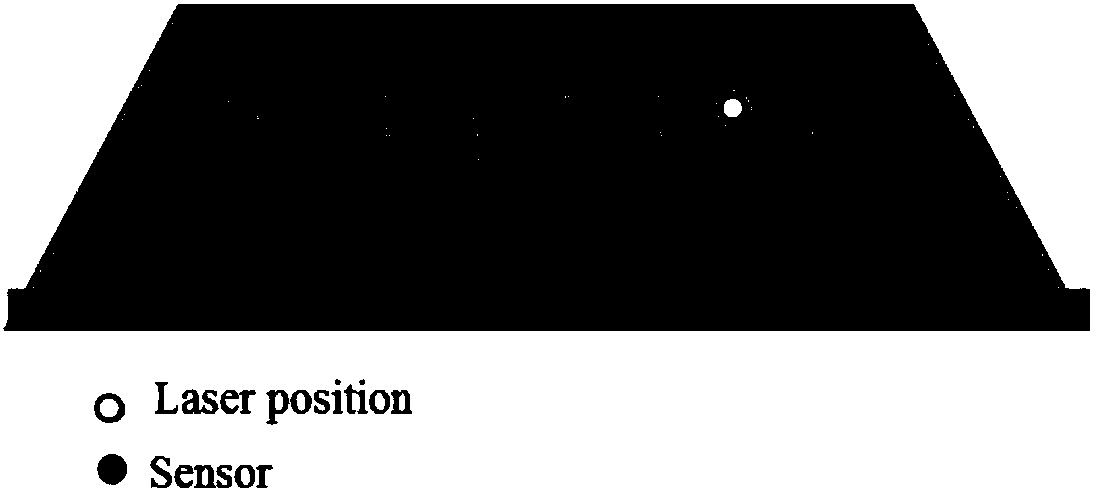

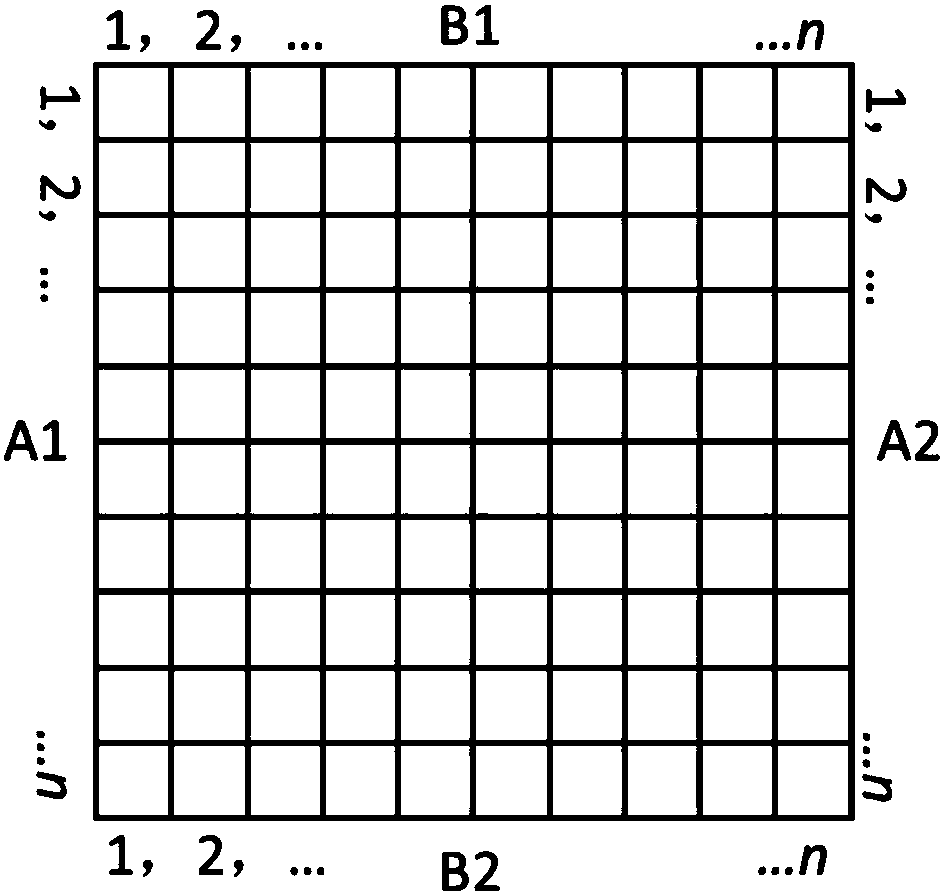

[0052] The goal of this embodiment is to detect aluminum plates with elliptical through holes (such as Figure 8 ). Aluminum plate model such as Picture 9 As shown, the major axis of the elliptical through hole is 15mm, the minor axis is 12mm, and the thickness of the aluminum plate is 5mm. In order to simplify the experiment, the elliptical through hole is regarded as damage, although in actual situations the elliptical through hole is visible to the naked eye, it does not Damage category. Irradiating the aluminum plate with a laser pulse (8.5 ns) produces a Lamb wave, the main components of which are S0 mode and A0 mode, and the energy of the wave is mainly concentrated between 100kHz and 200kHz. In this frequency domain, the wavelength of the A0 mode is about 10mm; the wave speeds of the S0 mode and A0 mode are about 5000m / s and 3000m / s.

[0053] Use the method of the invention to detect:

[0054] Step 1. Detect the attenuation rate of Lamb wave in the aluminum plate. In an ...

Embodiment 2

[0061] The goal of this embodiment is to detect aluminum plates with unpierced cracks. Aluminum plate model such as Picture 12 As shown: the length of the crack is 20mm, the width is 2mm, and the depth is 2.5mm; the thickness of the aluminum plate is 5mm. In order to simplify the experiment, the non-penetrating crack is regarded as damage here. Select the surface where the crack is located as the laser scanning plane.

[0062] The detection steps and setting parameters are the same as in Example 1. Figure 13 Schematic diagram of the detection area.

[0063] The diagnosis result of this embodiment is as Figure 14 As shown: the red and green areas in the figure are the damage results diagnosed by the present invention, and the white ellipse represents the real damage. It can be seen that the crack damage can be accurately located, but its shape and size are about 50% different from the actual situation.

Embodiment 3

[0065] The goal of this embodiment is to detect delamination-containing carbon fiber reinforced composite laminates (such as Figure 15 Shown). The composite laminate structure used in the experiment is ((45° / 0° / -45° / 90°) 4 ] s , The plate thickness is 4.8mm. There is delamination in the middle of the composite laminate. The delamination is obtained by a low-speed impact of a 4.6kg weight by a hammer impact tester (Dynatup 9250HD). Figure 16 For the ultrasonic C-scan detection to obtain the delamination damage map: the scan surface is the impact surface and the result is Figure 16 a; the result of scanning the surface as the non-impact surface (the plane on the other side of the impact surface) is Figure 16 b.

[0066] Irradiating the carbon fiber reinforced composite material laminate with a laser pulse (8.5 ns) generates a Lamb wave, the main components of which are S0 mode and A0 mode, and the energy of the wave is mainly concentrated between 50kHz and 300kHz. In this frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com