Electric peak load regulation gas-fired cogeneration waste heat recycling device and method

A waste heat recovery device and cogeneration technology, which is applied in the field of heat exchange devices, can solve the problems of small space, difficult recovery of waste heat from flue gas, and lack of transformation conditions, so as to increase heating capacity, improve energy utilization efficiency, guarantee The effect of constant heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

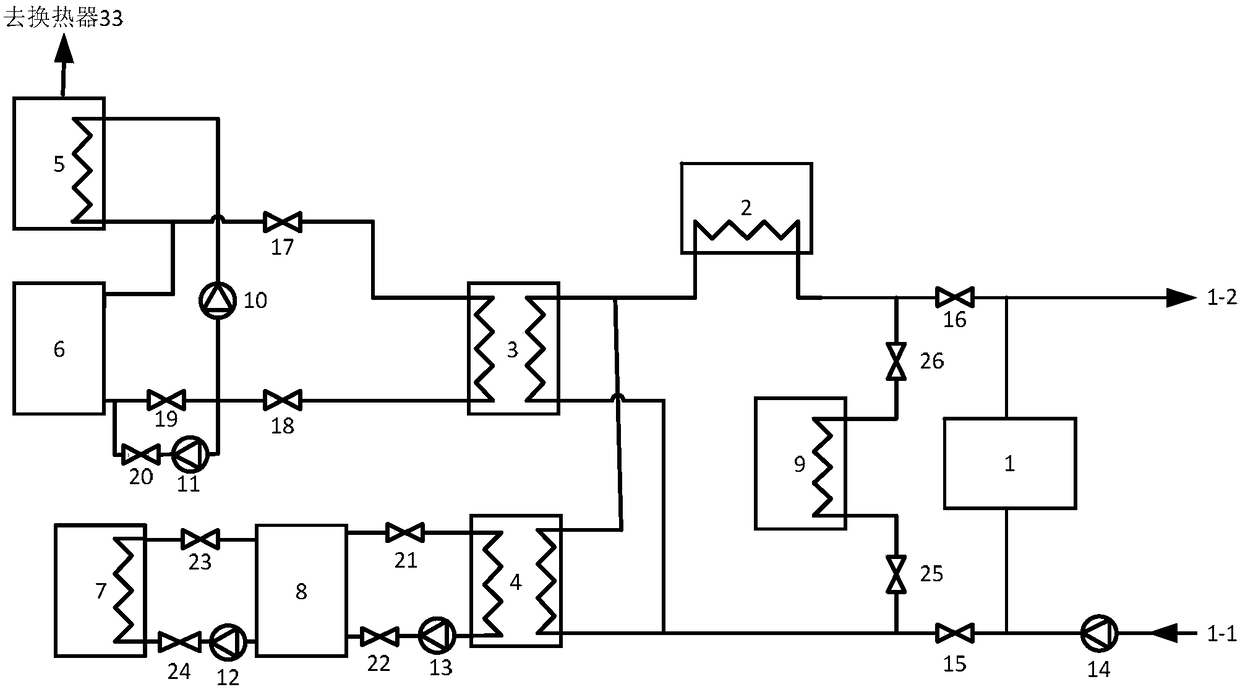

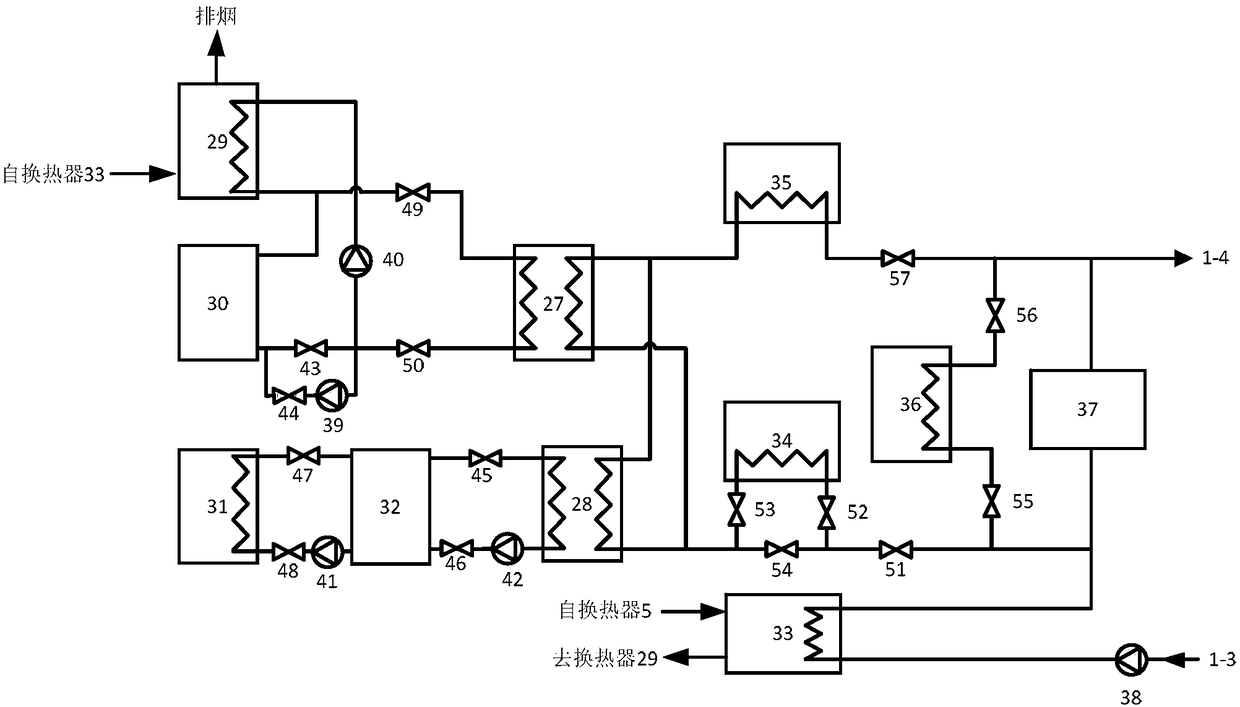

[0024] The power peak-shaving gas cogeneration waste heat recovery device provided by the present invention includes the heating system in the central city area and the heating system in the outgoing area arranged inside the power plant, and its design idea is to ensure that the original heat supply capacity of the heating network in the central city area remains unchanged. Under normal circumstances, the full heat of the flue gas is recovered, and the increased heating capacity is sent to the newly added heating area, and at the same time, the power peak-shaving capacity of the gas-fired power plant in winter is greatly increased.

[0025] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com