An optimized construction method for multi-arch tunnels

A construction method and technology of multi-arch tunnels, which are applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of hidden quality of top poured concrete voids, difficulties in installing and dismantling formwork, and slow construction progress, so as to ensure structural stress, The effect of fast speed and reduced process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

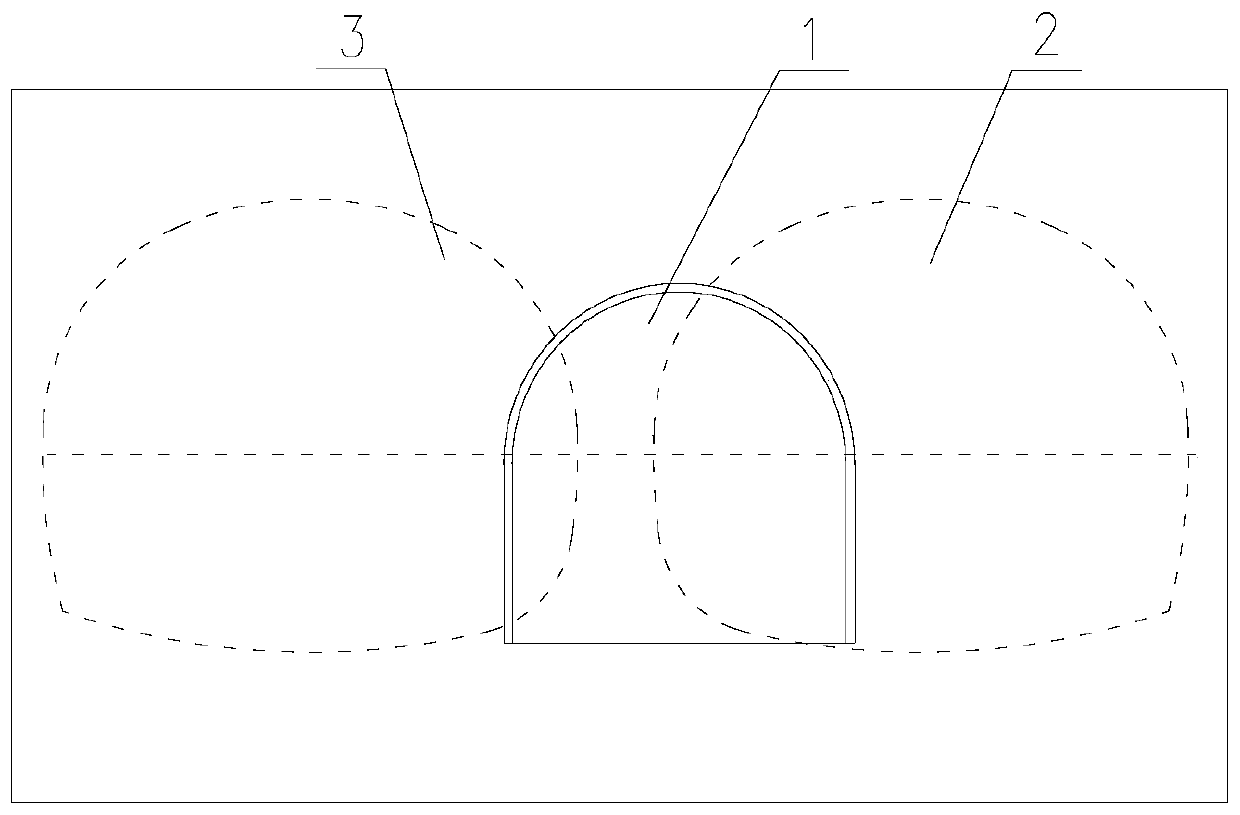

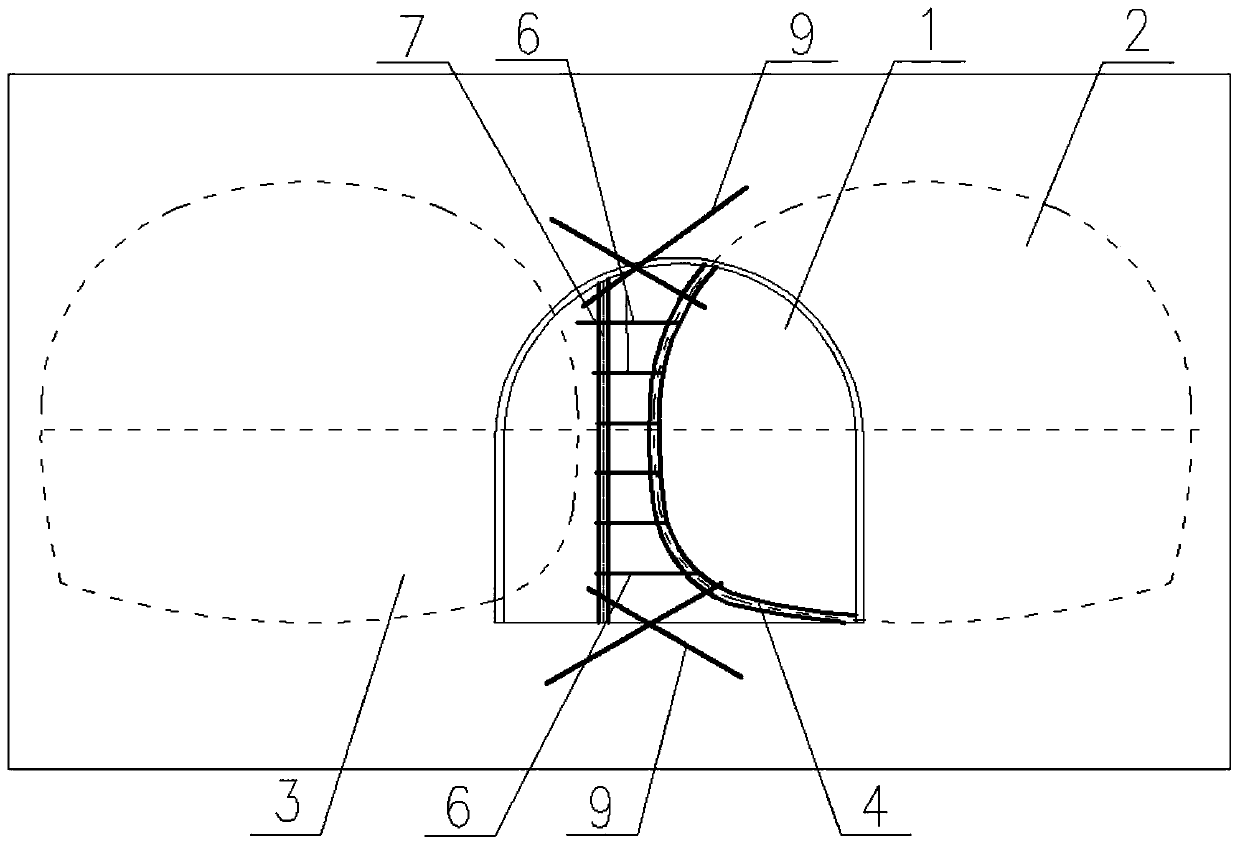

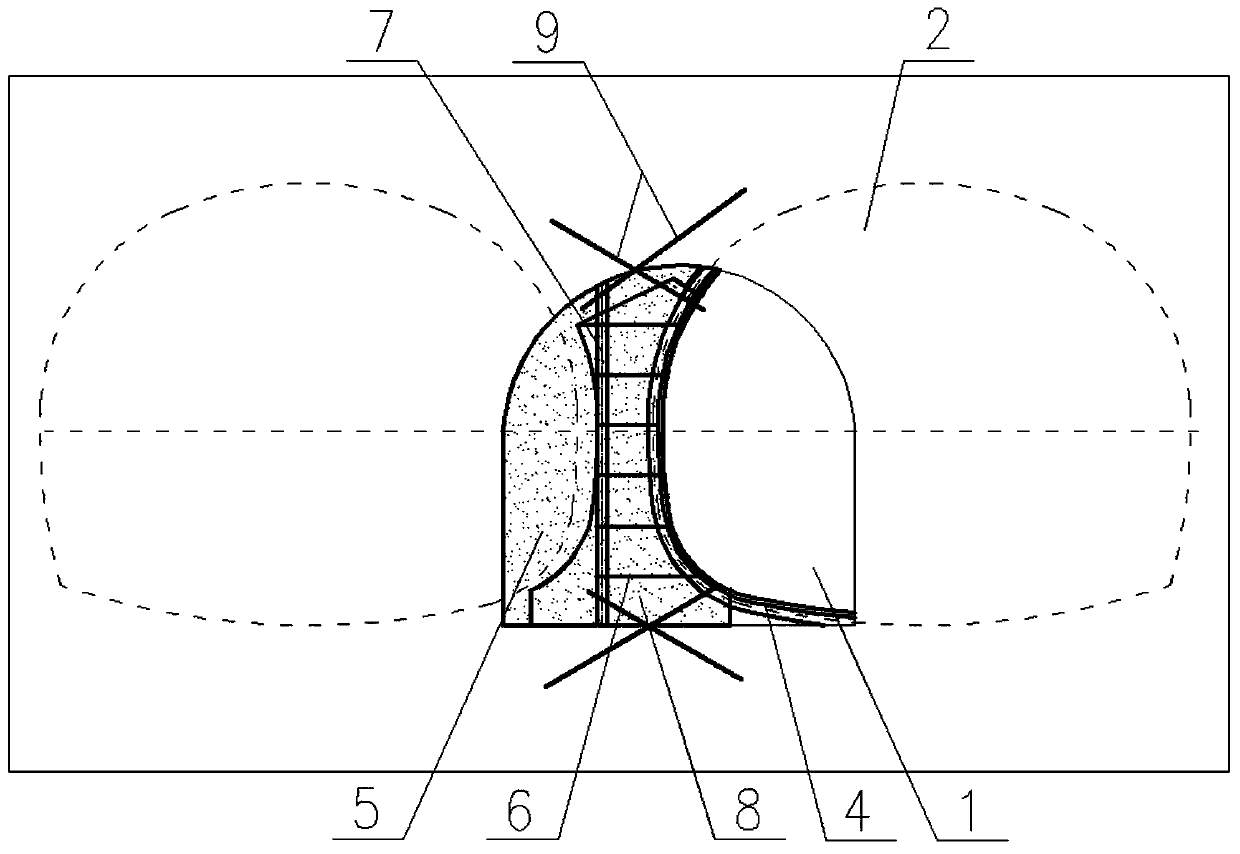

[0058] Such as Figure 1-5 Shown, a kind of multi-arch tunnel optimization construction method of the present invention comprises the following steps:

[0059] (1) Temporary support after the pilot tunnel 1 in mechanical excavation by step method;

[0060] (2) Install a profiled steel arch frame on the side of the middle pilot tunnel 1 near the first hole 2, and then carry out the construction of hanging nets, connecting bars, anchor rods and sprayed concrete, and form the primary support structure by installing profiled steel arch frames, hanging nets and sprayed concrete construction 4;

[0061] (3) Plain concrete 5 is integrally backfilled on the side of the middle pilot tunnel 1 near the rear tunnel 3;

[0062] (4) The first hole 1 is mechanically excavated by the step method, and the initial support is closed to form a ring;

[0063] (5) The rear tunnel 3 is mechanically excavated by the step method, and the initial support is closed to form a ring.

[0064] Wherein, ...

Embodiment 2

[0071] Such as Figure 1-5 Shown, a kind of multi-arch tunnel optimization construction method of the present invention comprises the following steps:

[0072] (1) Temporary support after the pilot tunnel 1 in mechanical excavation by step method;

[0073] (2) Install a profiled steel arch frame on the side of the middle pilot tunnel 1 near the first hole 2, and then carry out the construction of hanging nets, connecting bars, anchor rods and sprayed concrete, and form the primary support structure by installing profiled steel arch frames, hanging nets and sprayed concrete construction 4;

[0074] (3) Plain concrete 5 is integrally backfilled on the side of the middle pilot tunnel 1 near the rear tunnel 3;

[0075] (4) The first hole 1 is mechanically excavated by the step method, and the initial support is closed to form a ring;

[0076] (5) The rear tunnel 3 is mechanically excavated by the step method, and the initial support is closed to form a ring.

[0077] Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com