Manufacturing and use method of masonry mortar spreading tool

A technology of masonry mortar and tools, applied in the field of masonry mortar paving, can solve the problem of inability to ensure the thickness and fullness of horizontal mortar joints and construction quality, the thickness of horizontal mortar joints does not meet the requirements, and it is difficult to ensure the quality and efficiency of masonry construction, etc. problem, to achieve the effect of low cost, ensuring thickness and fullness, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] see Figure 1 to Figure 6 , the present invention provides a technical solution: a method for making and using a masonry mortar paving tool includes the following steps:

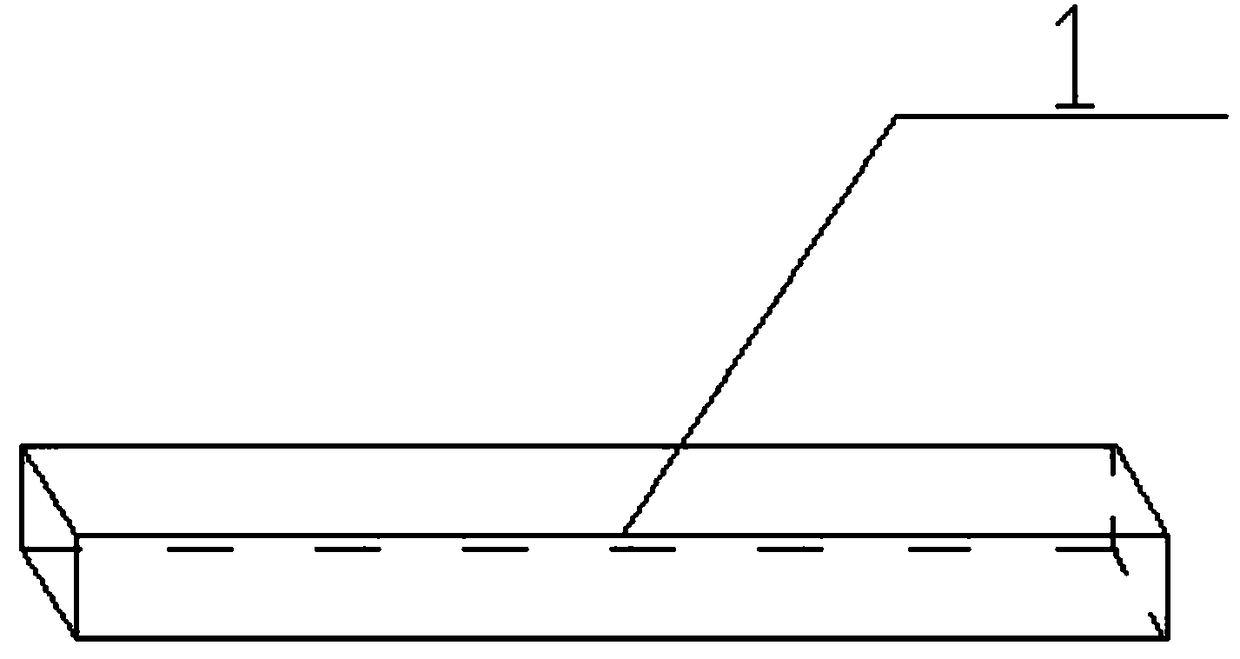

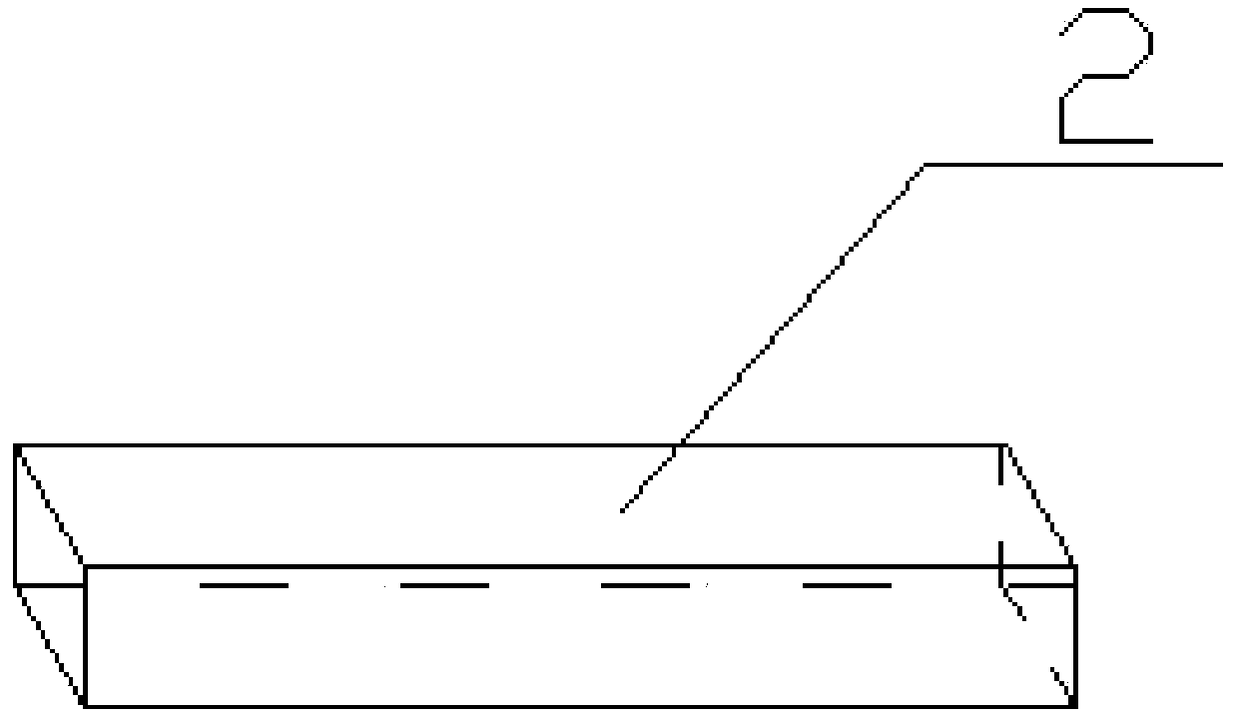

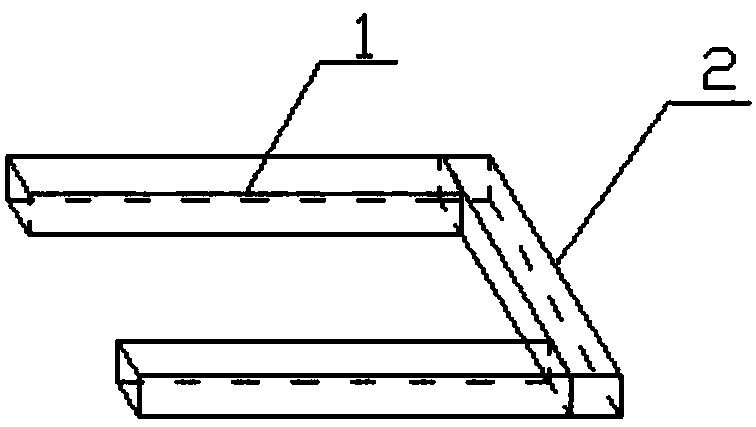

[0023] A. According to the requirements of the width of the horizontal mortar joints in the masonry of the tower wall, select a suitable type of square tube, and then process the square tube into two long and one short three sections according to the width of the wall, that is, two long side square tubes (1) , a short-side square tube (2) at one end, welding the long-side square tube (1) and the short-side square tube (2) into a U-shaped frame according to the size;

[0024] B. According to the size of the inner opening of the U-shaped frame, process the selected steel plate into three rectangular steel sheets (3), the longer steel sheet is welded to the long side of the inner opening of the U-shaped frame, and the other two shorter pieces are welded to the The two short sides of the inner mouth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com