Hydraulic control system for microwave heating asphalt pavement hot in-place recycling device

A hydraulic control system and asphalt pavement technology, applied in the field of hydraulic control system, can solve the problems of low heating efficiency, difficult heating of complex roads, and inability to control the space position of heating devices, and achieve the effect of reducing labor intensity and simplifying operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings.

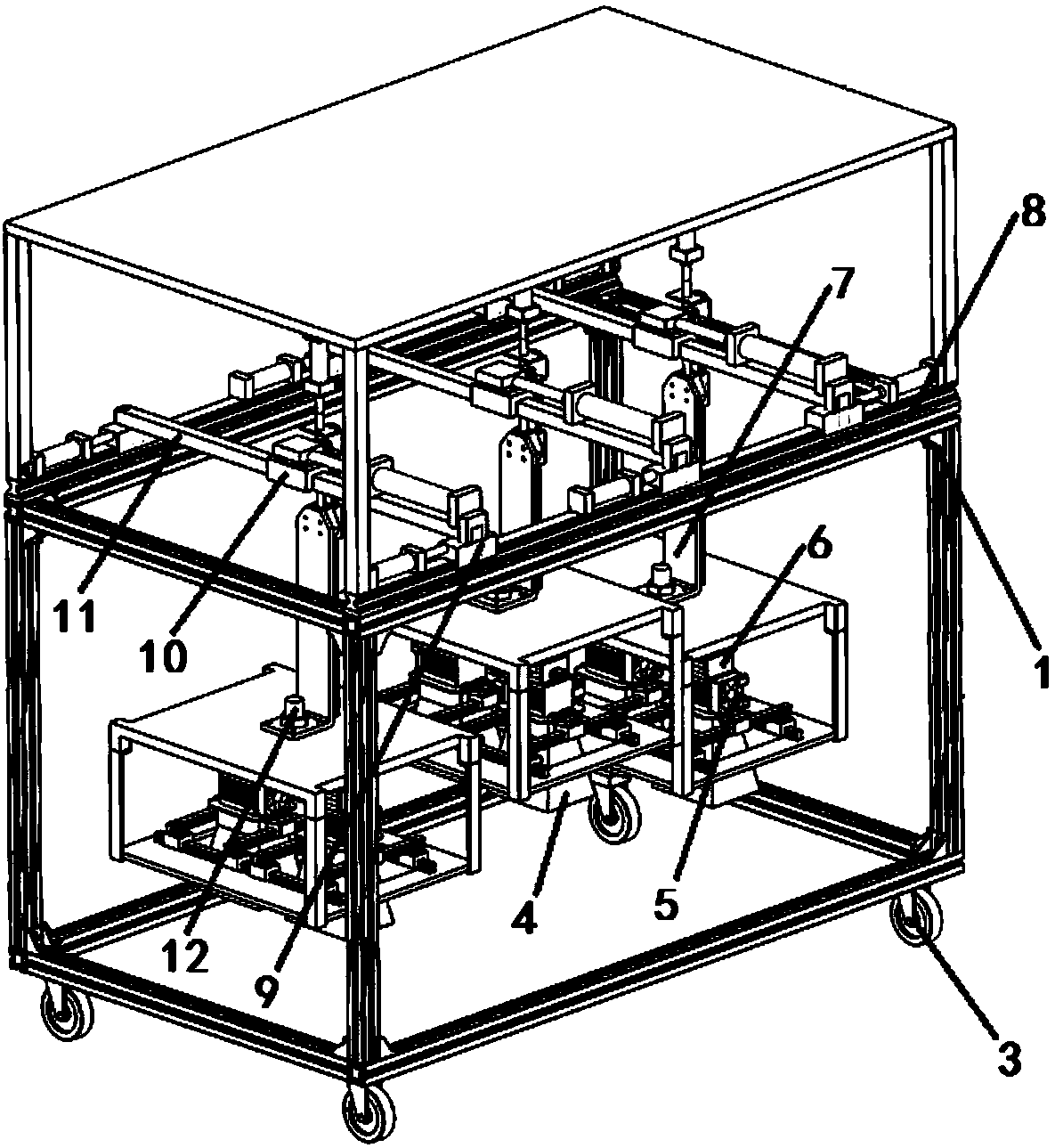

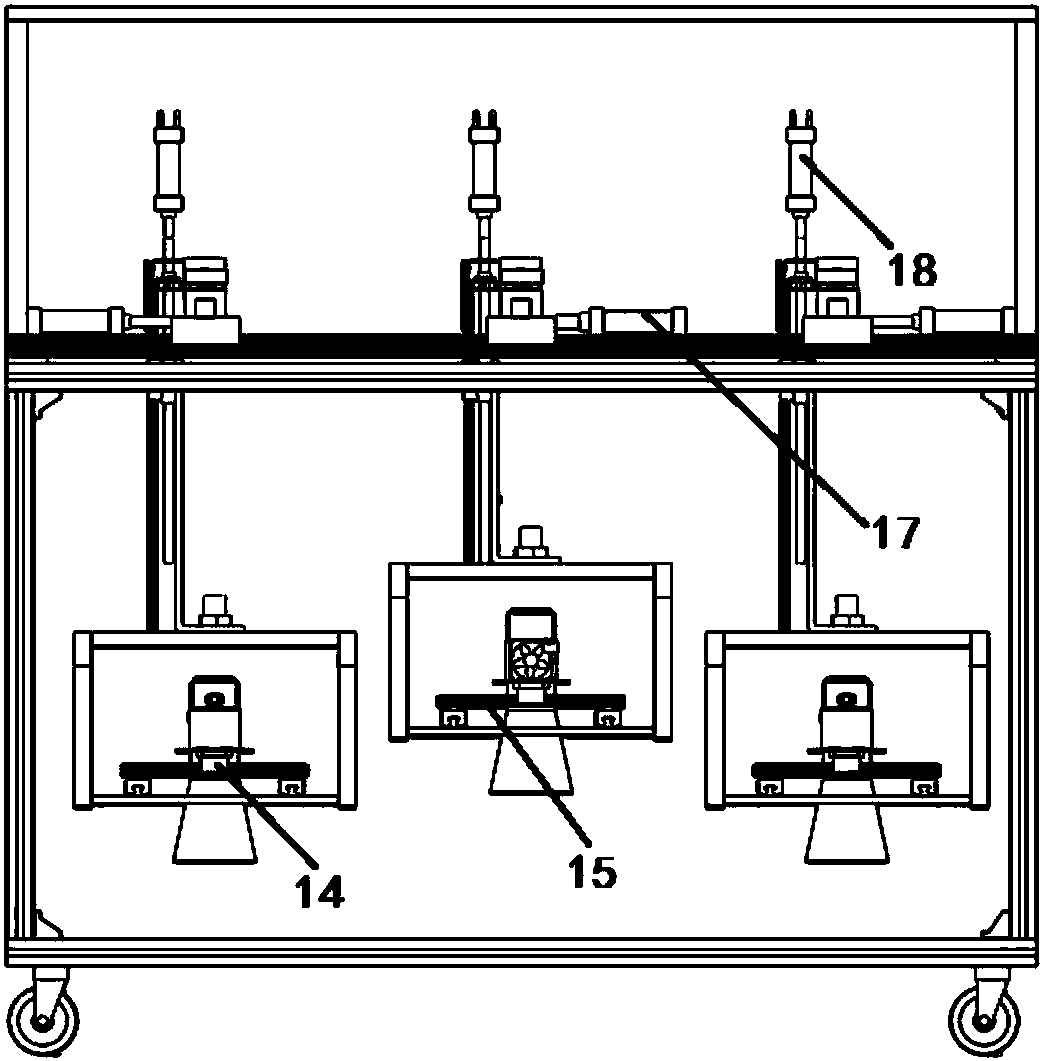

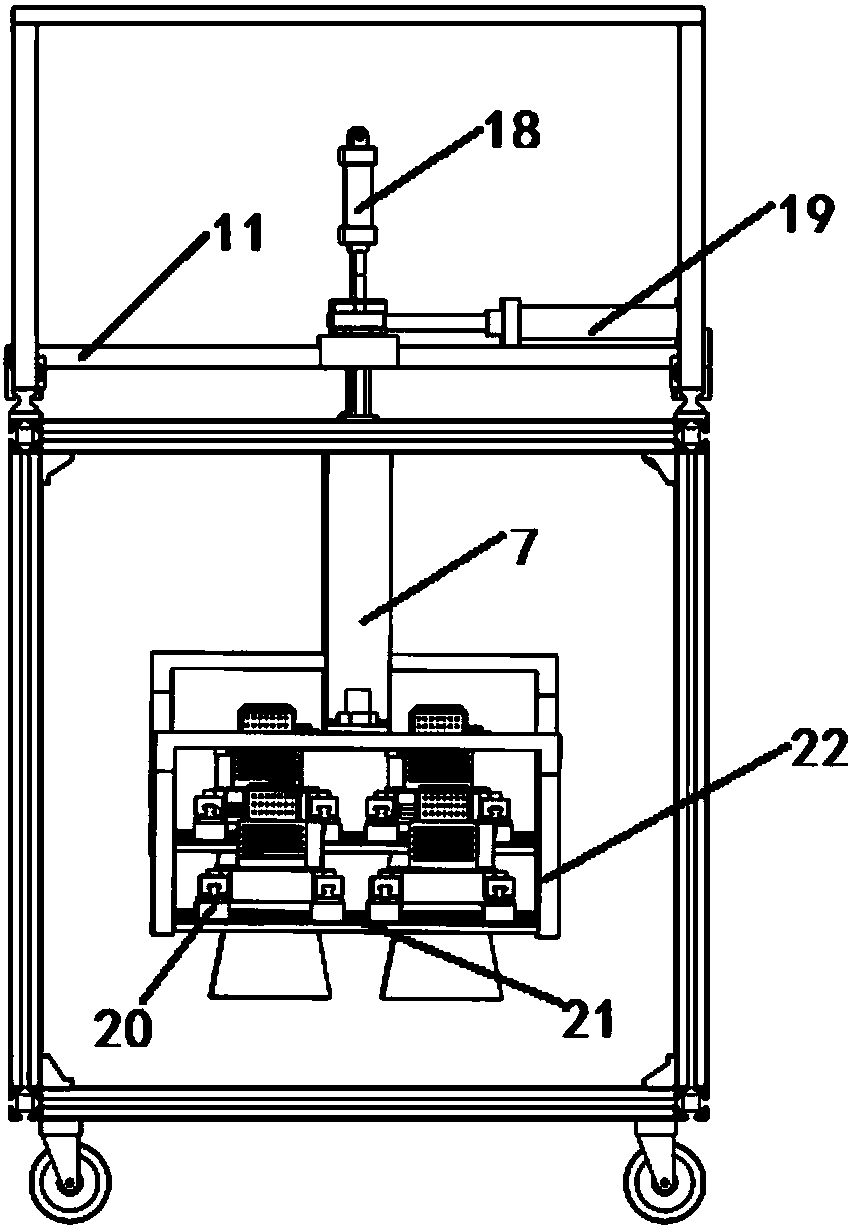

[0027] A hydraulic control system for a microwave-heated asphalt pavement hot-in-place regeneration device, such as Figure 1-3 As shown, the in-situ heat regeneration device for microwave heating asphalt pavement includes a main frame, a space adjustment device and a heating device. The main frame 1 is used to carry all heating devices and space adjustment devices, and bears most of the weight. Therefore, the steel plate is used as the manufacturing material, and the main frame with steel as the casting material has sufficient load-bearing rigidity and load-bearing strength, so no compression will occur Deformation situation. The whole outside of the main frame is provided with a metal shielding net, and the bottom of the main frame is equipped with a universal wheel 3 with locks. The top of the main frame includes two first sliding guide rails 8 that are parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com