Vertical two-section type blast furnace pulverized coal injection device

A two-stage, pulverized coal technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., to solve the problems of gas flow distribution and column permeability, improve gas utilization, and improve coal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

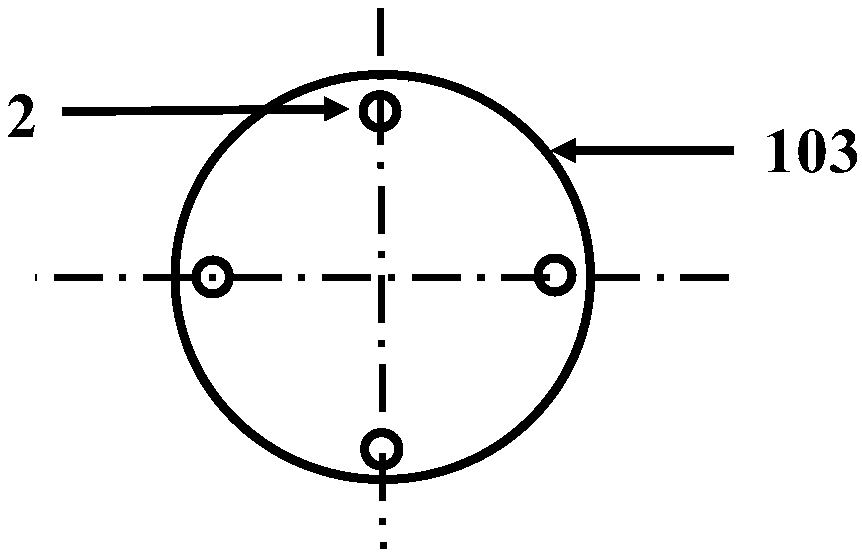

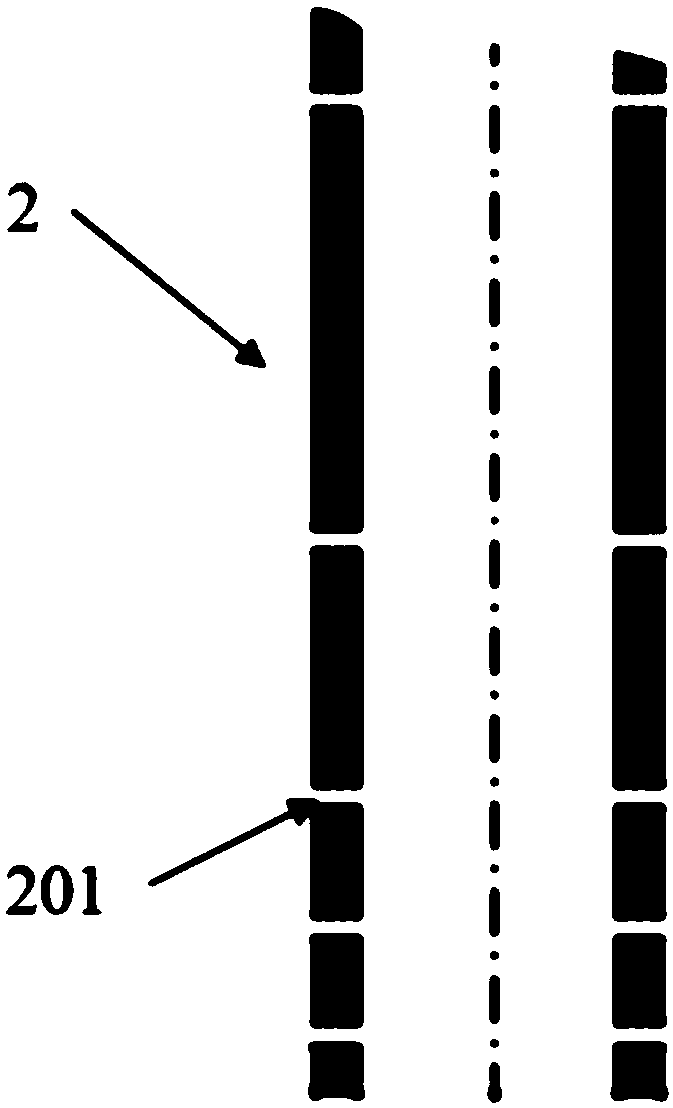

[0045] like Figure 1-2 Shown: This embodiment discloses a vertical two-stage blast furnace pulverized coal injection device, including a blast furnace 1 and a plurality of two-stage pulverized coal spray guns 2 arranged inside the blast furnace 1 .

[0046] The blast furnace 1 described here refers to the ironmaking blast furnace. The improvement in this embodiment is mainly to provide a complete set for the ironmaking blast furnace in the prior art to increase the amount of pulverized coal injection and improve the gas flow distribution in the furnace. A device to improve the production efficiency of ironmaking.

[0047] The device described here is a two-stage pulverized coal spray gun 2 .

[0048] In detail, the plurality of two-stage pulverized coal spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com