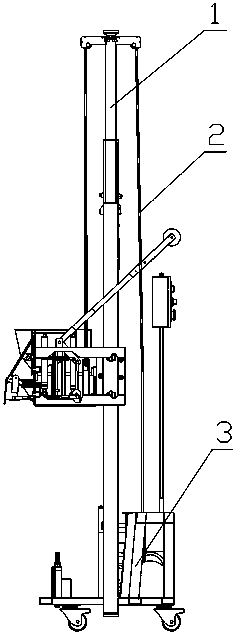

Device for passing of lifting steel wire rope of ash hopper of wall plastering machine

A technology of powder wall machine and wire rope, which is applied in hoisting devices, safety devices of hoisting equipment, construction, etc. It can solve problems such as affecting the operation of hoisting wire ropes, wire rope deviation stuck, and wire rope running poorly, etc., to achieve good promotion and use value , prevent overweight conditions, and ensure smooth and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

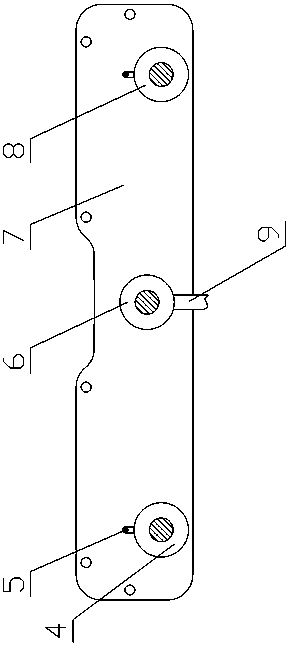

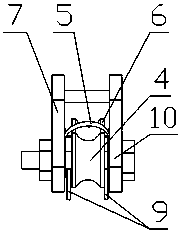

[0012] see figure 2 , image 3 and Figure 4 , the present invention is a device for lifting the steel wire rope of the powder wall machine ash hopper, which has a mounting seat connected to the top of the powder wall machine column 1, the mounting seat is composed of a mounting plate A7 and a mounting plate B10, the mounting plate A and the mounting plate The plates B are connected by welding round rods. The fixed pulley A4 and the fixed pulley B8 are symmetrically arranged on the left and right sides of the installation seat. There is also a fixed pulley C6 inside the installation seat located in the middle of the fixed pulley A and the fixed pulley B. The pulley C is connected with the mounting plate A and the mounting plate B through the wheel shaft, the installation height of the fixed pulley C is higher than the installation height of the fixed pulley A and the fixed pulley B, and the two ends of the wheel shaft of the fixed pulley C are equipped with pressure sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com