Robot for removing sausage casing of ham sausage

A ham sausage and robot technology, applied in the field of food processing, can solve the problems of inconvenience, time-consuming, labor-intensive, and laborious, and achieve the effects of convenient installation and use, simple structure, and powerful functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

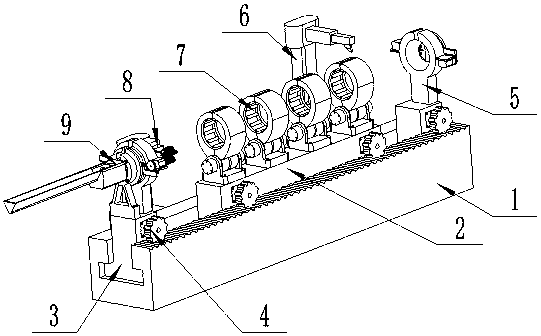

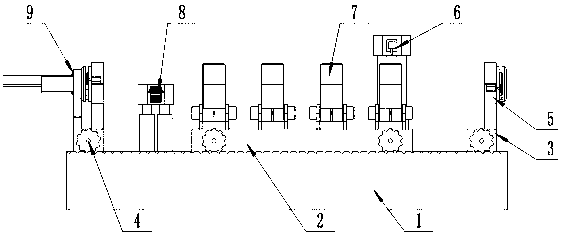

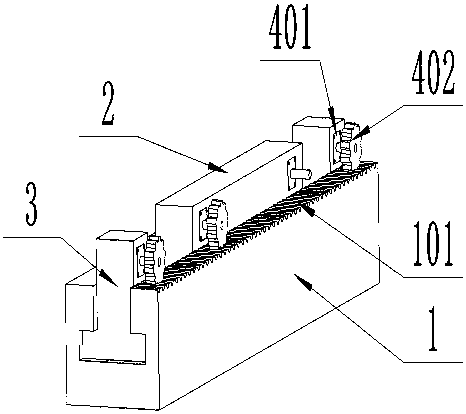

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12As shown, a ham sausage casing removal robot includes a first slide rail part 1, a first slider 2, a second slider 3, a first stepping motor part 4, an end cutting knife part 5, and a casing cutting knife part 6. Sausage rolling clamp part 7, casing reel part 8, bamboo skewer screw-in part 9, in which the first slide rail gear train 101, the first stepping motor 401, the first gear 402, and the end cutter base 501 , side motor mounting ear 502, cutter mounting ring 503, cutter limit post 50301, cutter 504, cutter cover 505, second stepper motor 50601, second gear 50602, casing cutter base 601, first retractable Rod 602, first telescopic rod end fixing member 603, first electric cylinder 604, casing cutting knife 605, sausage roll clamp base 701, first drive motor 702, second drive motor 703, first roll guard cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com