Robot for cutting wood plate

A robot and wood board technology, applied in the field of robots, can solve the problems of hanging hands, cutting irregular cutting positions, and reducing work efficiency, and achieves the effect of preventing random flying, ensuring safety, and ensuring cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

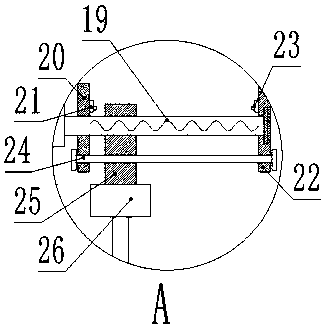

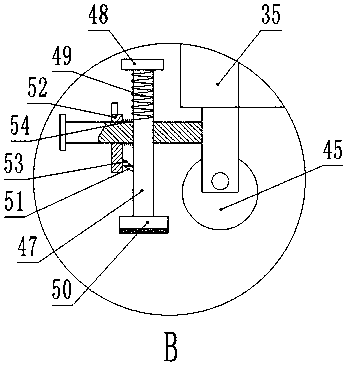

[0017] Embodiment 1: as Figure 1-5As shown, a robot for cutting wooden boards includes a workbench 1, on which a cutting hole 2 is arranged, and positioning rods 3 are fixed at the four corners of the top edge of the workbench 1, and the top of the positioning rod 3 A support bar A4 is fixedly provided, and a fixed vertical bar A5 is fixedly provided on the top surface of the support bar A4, and a support bar B6 is fixedly arranged between the two fixed vertical bars A5, and the center of the bottom surface of the support bar B6 A swing rod 8 is fixedly provided, and a sliding rod A9 and a connecting rod 14 are respectively hinged at the edge of the top surface and the bottom surface of the swing rod 8, and the top end of the sliding rod A9 is fixedly connected to the limit plate 10 through the support cross bar B6 A hydraulic telescopic rod 11 and a sleeve B28 are hinged at the edge of the top and bottom surfaces on the other side of the swing rod 8, the hydraulic telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com