Mine safety production monitoring method

A technology for safe production and mines, applied in the direction of comprehensive factory control, comprehensive factory control, program control, etc., can solve the problem of difficult to find mutually compatible systems, and achieve a large number of measuring points, strong anti-interference, and simple interface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

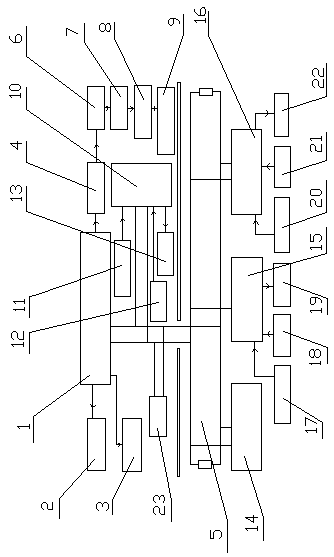

[0014] Mine safety production monitoring method, using CAN bus to form a peer-to-peer inter-layer field bus network. Using priority arbitration technology, when bus access conflicts occur, high-priority information can still be sent, which is more suitable for data processing in mines. For systems with high requirements for transmission and real-time control, the CAN bus communication protocol and interface are simple, the transmission rate is high, it has a variety of error detection methods, and it has strong anti-interference. It encodes communication data blocks and easily realizes point-to-point communication. The length of the data segment is up to 8 bytes, which can meet the general requirements of control commands, working status and test data. For traditional mine reconstruction, only the RS-485 nodes need to be replaced by CAN nodes, and the information in the original system The transmission interface, monitoring system software and workstation are respectively repla...

Embodiment 2

[0016] A mine safety production monitoring method, the monitoring system host is respectively connected to the dispatching panel 2, the camera 3, the video converter 4 and the CAN bus 5, the video converter is connected to the modulator 6, and the modulator is connected to the matching The device 7 is connected, the matching device is connected to the TV network server 8, the TV network server is connected to the industrial TV system 9, the CANL output terminal and the CANH output terminal of the CAN bus are connected to the CAN workstation interface 10 on the well, The CAN workstation interface on the well is respectively connected with the sensor 11 on the well, the power supply box 12 on the well and the power breaker 13 on the well, and the CAN bus is respectively connected to the CAN workstation interface one 14, the CAN workstation interface two 15 and the CAN workstation interface in the well Three 16 connections.

[0017] Example 2:

[0018] According to the mine safe...

Embodiment 3

[0020] According to the mine safety production monitoring method described in embodiment 1 or 2, the CANH output terminal and the CANL output terminal of the CAN bus are connected to the lightning arrester 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com