Laminated lithium ion battery core and assembly method thereof and laminated lithium ion battery comprising same

A lithium-ion battery and assembly method technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of hidden safety hazards in the use process, complicated preparation methods, and high costs, and achieve prolonging service life, simple operation, and avoiding waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

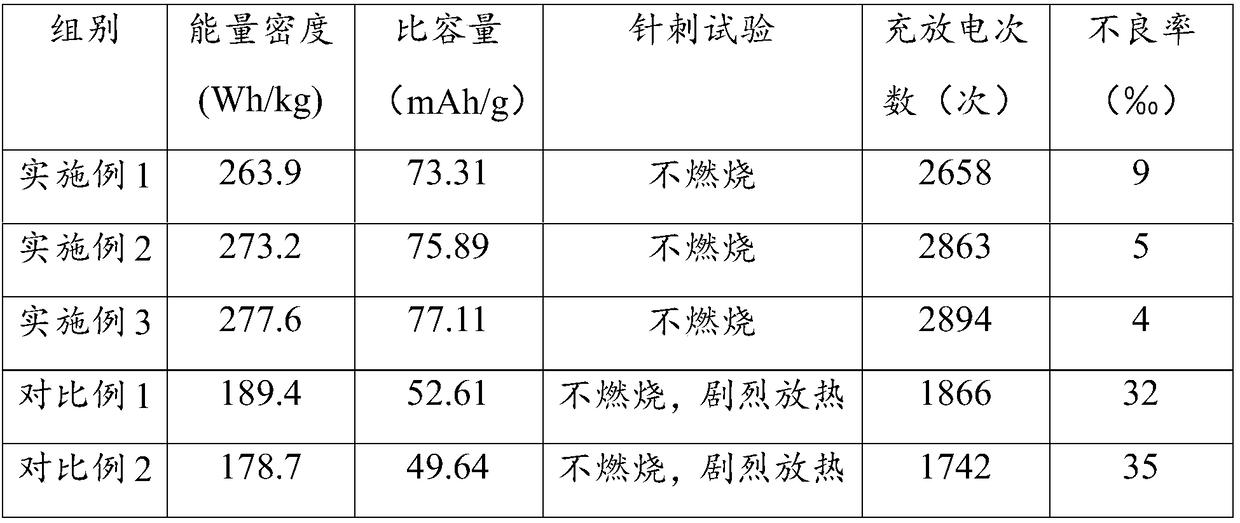

Embodiment 1

[0047] This embodiment provides a laminated lithium-ion battery, and the preparation method of the laminated lithium-ion battery includes the following steps:

[0048] (a), providing 3 gap-coated positive electrode strips and 3 gap-coated negative electrode strips of the same specification, and arranging the positive electrode strips and the negative electrode strips at intervals.

[0049] (b), the separator strip is laid on the gap-coated positive electrode sheet strip and the gap-coated negative electrode sheet strip provided in step (a), so that the separator strip includes positive electrode sheets and negative electrode sheets arranged at intervals .

[0050] (c) Fix the gap-coated positive electrode sheet strip, the gap-coated negative electrode sheet strip, and the separator strip by heating and rolling.

[0051] (d) Cutting along both sides of the separator strip by a cutting device to obtain positive and negative electrode sheet separators.

[0052] (e) Assembling t...

Embodiment 2

[0055] This embodiment provides a laminated lithium-ion battery, and the preparation method of the laminated lithium-ion battery includes the following steps:

[0056] (a), provide 3 gap-coated positive electrode strips and 3 gap-coated negative electrode strips of the same specification, and arrange the positive electrode strips and the negative electrode strips in parallel on the same plane , to ensure that the distance between the positive electrode strip and the negative electrode strip is not less than 1 / 2 of the thickness of the positive electrode and the negative electrode, and that each positive electrode and each negative electrode are aligned on the same vertical line On the top, the positive pole tab and the negative pole tab are respectively located in opposite directions of the separator strip.

[0057] (b), the separator strip is laid on the gap-coated positive electrode sheet strip and the gap-coated negative electrode sheet strip provided in step (a), so that t...

Embodiment 3

[0064] This embodiment provides a laminated lithium-ion battery, and the preparation method of the laminated lithium-ion battery includes the following steps:

[0065] (a), provide 3 gap-coated positive electrode strips and 3 gap-coated negative electrode strips of the same specification, and arrange the positive electrode strips and the negative electrode strips in parallel on the same plane , to ensure that the distance between the positive electrode strip and the negative electrode strip is not less than 1 / 2 of the thickness of the positive electrode and the negative electrode, and that each positive electrode and each negative electrode are aligned on the same vertical line On the top, the positive pole tab and the negative pole tab are respectively located in opposite directions of the separator strip.

[0066] (b), the separator strip is laid on the gap-coated positive electrode sheet strip and the gap-coated negative electrode sheet strip provided in step (a), so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com