A combined electrolyte and high specific energy silicon-based lithium ion battery containing the combined electrolyte

A lithium-ion battery, electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as failure to achieve results, and achieve the effects of avoiding negative effects, improving safety, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

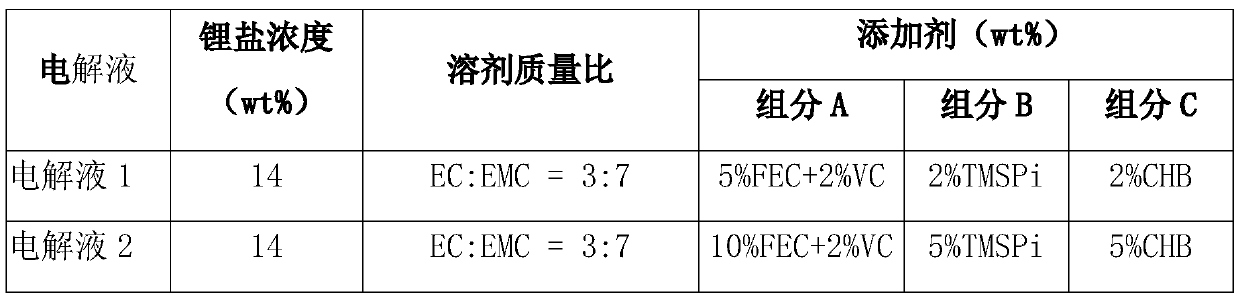

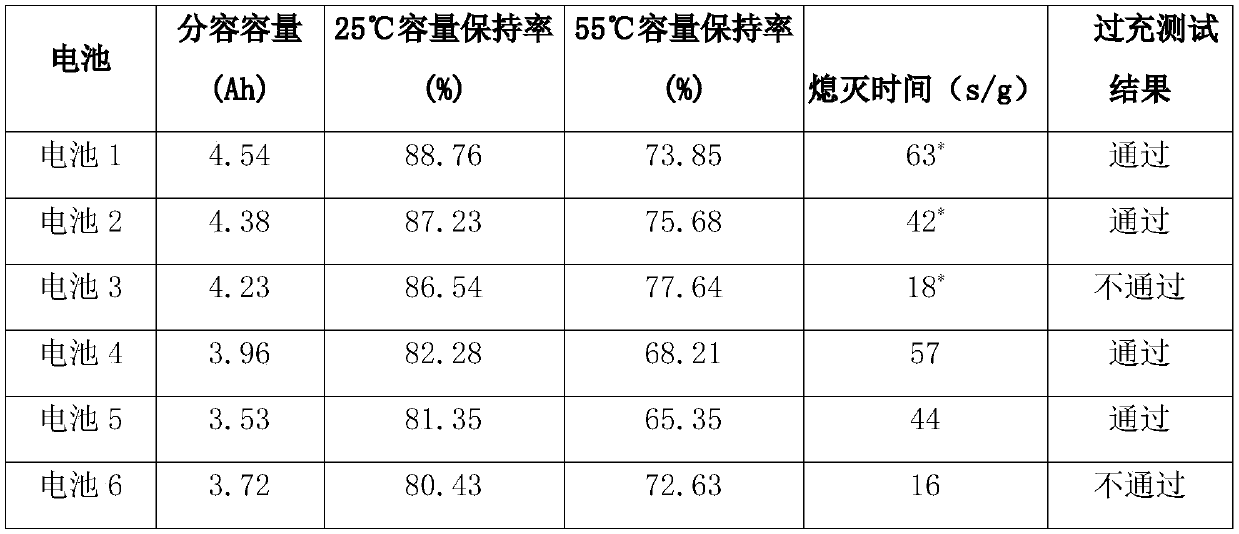

[0025] Preparation of Electrolyte 1 and Experimental Battery 1

[0026] (1) Preparation of positive electrode sheet

[0027] Mix the positive electrode active material NMC811 ternary material, conductive agent acetylene black, and binder polytetrafluoroethylene according to the mass ratio NMC811: acetylene black: polytetrafluoroethylene = 95:2.5:2.5, add N-methylpyrrolidone, fully Stir and mix to form a uniform positive electrode slurry, which is evenly coated on a 15-micron thick aluminum foil, and dried to obtain a positive electrode sheet.

[0028] (2) Negative sheet preparation

[0029] Negative electrode active material silicon oxide-graphite (SiO-C) negative electrode material, conductive agent acetylene black, binder styrene-butadiene rubber, thickener sodium carboxymethyl cellulose according to the mass ratio of silicon-based negative electrode material: acetylene black: butadiene Styrene rubber: thickener = 95:2:2:1 for mixing, add deionized water, stir and mix well...

Embodiment 2

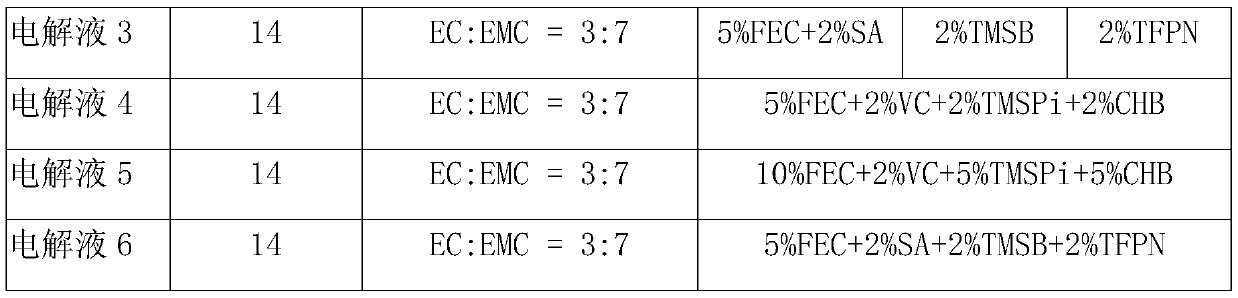

[0037]The preparation of combined electrolyte 2 and experimental battery 2 is basically the same as the preparation process of combined electrolyte 1 and experimental battery 1 in Example 1, the only difference is that in step (3) component A is added to account for the entire combined electrolytic Liquid quality 10% fluoroethylene carbonate (FEC), 2% ethylene carbonate (VC); Component B adds trimethylsilane phosphite (TMSPi) accounting for 5% of the entire combined electrolyte mass; In part C, add cyclohexylbenzene (CHB) accounting for 5% of the mass of the entire electrolyte.

[0038] The final high specific energy silicon-based needle-ion battery is denoted as experimental battery 2.

Embodiment 3

[0040] The preparation of combined electrolyte solution 3 and experimental battery 3 is basically the same as the preparation process of combined electrolyte solution 1 and experimental battery 1 in Example 1, the only difference is that in step (3) component A is added to account for the entire combined electrolytic solution Liquid quality 5% fluoroethylene carbonate (FEC), 2% succinic anhydride (SA); Component B added trimethylsilane borate (TMSPi) accounting for 2% of the entire combined electrolyte mass; In part C, hexafluorocyclotriphosphazene (TFPN) accounting for 2% of the mass of the entire combined electrolyte was added.

[0041] The final high specific energy silicon-based needle-ion battery is denoted as experimental battery 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com