OLED array substrate, display device and method for repairing dark spots thereof

An array substrate and repair method technology, applied in the field of organic light-emitting diode array substrates, can solve problems such as dark spots, anode and cathode short circuits, damage to surrounding display areas, etc., to achieve the effect of eliminating bright spots and returning pixels to normal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

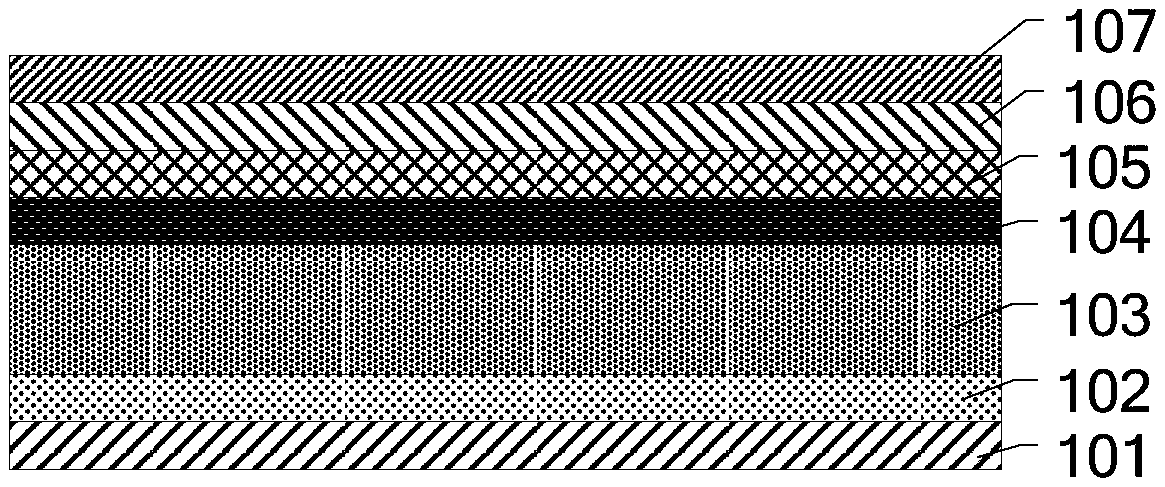

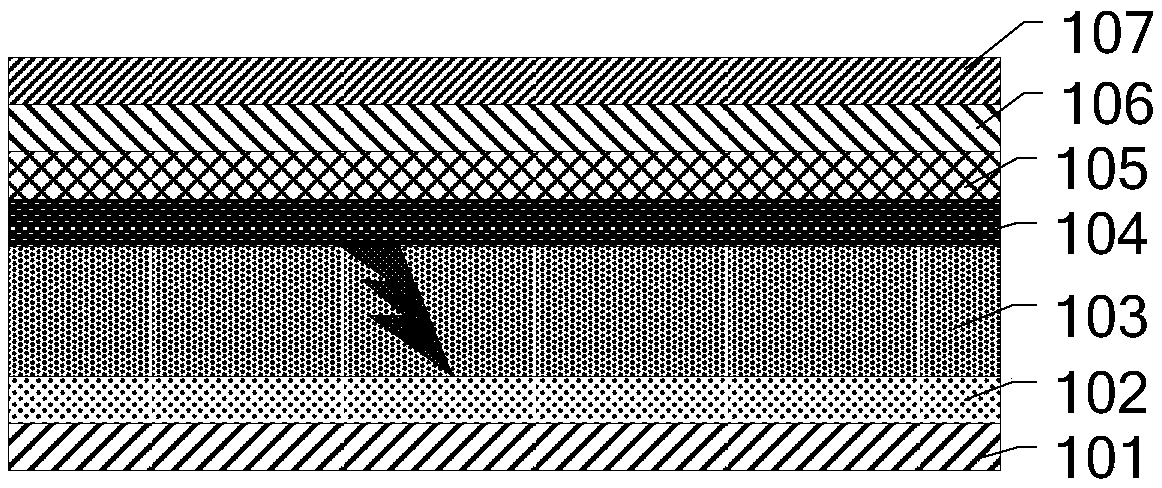

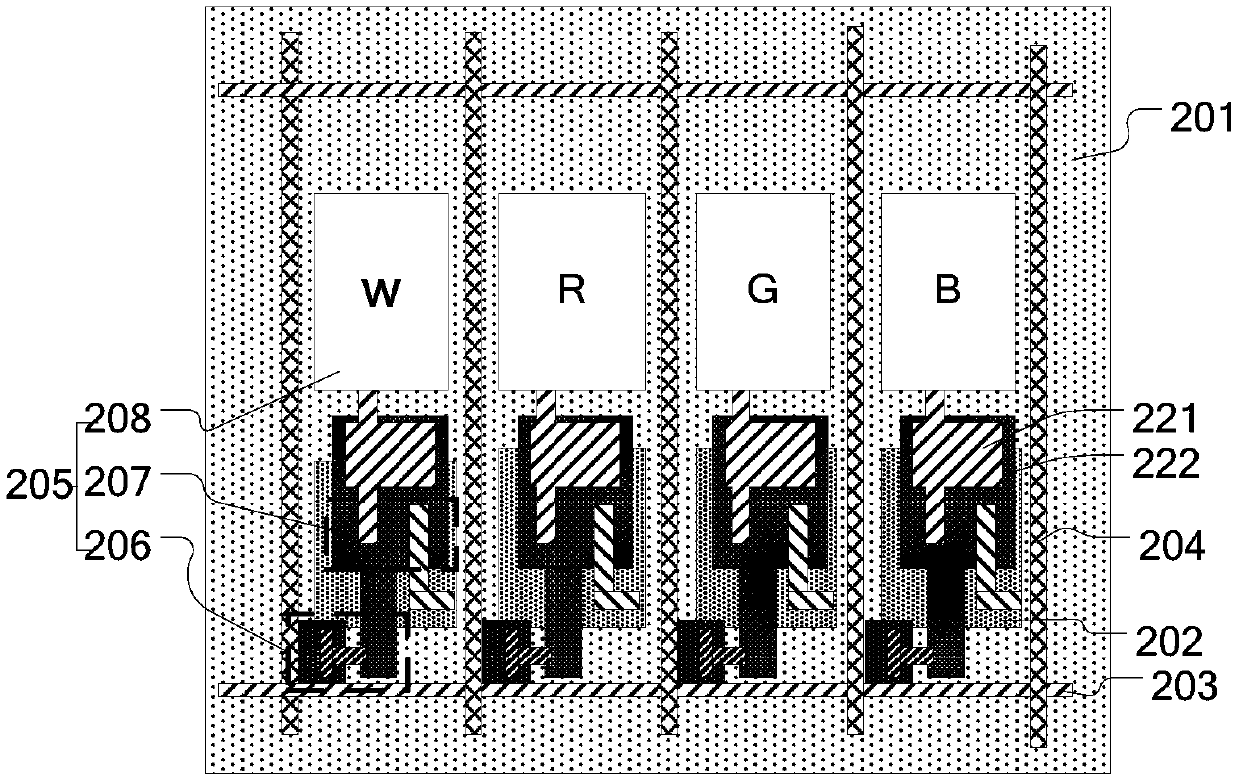

[0050] This embodiment provides an organic light emitting diode (OLED) array substrate, for example, image 3 A schematic plan view of an organic light emitting diode (OLED) array substrate provided in this embodiment, Figure 4a A schematic cross-sectional structure diagram of an organic light emitting diode (OLED) array substrate provided in this embodiment, Figure 4b A schematic cross-sectional structure diagram of another organic light emitting diode (OLED) array substrate provided in this embodiment.

[0051] Such as image 3 with Figure 4a , Figure 4b As shown, the OLED array substrate includes: a base substrate 201, a power line 202 arranged on the base substrate 201, a connecting part ( image 3 , Figure 4a with Figure 4b Not shown in ), gate line 203 and data line 204; pixel structure 205 arranged in the area defined by the intersection of gate line 203 and data line 204, pixel structure 205 includes switching transistor 206, driving transistor 207 and OLED...

Embodiment 2

[0086] This embodiment provides a display device, including any organic light emitting diode (OLED) array substrate in Embodiment 1, and may also include a gate drive circuit, a data drive circuit, and a power supply, etc., and the gate line is connected to the gate drive circuit. , the data line is connected to the data driving circuit, and the power wiring is connected to the power supply. The display device can be any product or component with a display function such as an OLED panel, a mobile phone, a tablet computer, a TV set, a monitor, a notebook computer, a digital photo frame, and a navigator.

[0087] The organic light emitting diode (OLED) array substrate included in the display device of this embodiment is the same as the above-mentioned Figure 4a , Figure 4b as well as Figure 4c Any one of the organic light emitting diode (OLED) array substrates shown has the same structure, and its technical effects and implementation principles are the same, and will not be...

Embodiment 3

[0090] This embodiment provides an organic light emitting diode (OLED) array substrate in the first embodiment and a method for repairing dark spots of the display device in the second embodiment, Figure 10 A flow chart of a method for repairing dark spots provided in this embodiment, such as Figure 10 Shown, this preparation method comprises the steps:

[0091] Step 101, electrically connecting the power line and the first electrode;

[0092] Step 102, applying a voltage to the first electrode through the power line so that the first electrode and the second electrode are no longer short-circuited;

[0093] Step 103, electrically isolating the power line and the first electrode.

[0094] For example, the first laser irradiation is performed on the connection part corresponding to the pixel structure to be repaired for laser welding, and the power line and the first electrode are welded by controlling the energy and time of laser irradiation to electrically connect the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com