Ultra-high temperature and radiation resistant liquid level control cables

A liquid level control, radiation-resistant technology, used in insulated cables, cables with double-stranded/quad-stranded, thermometer applications, etc., can solve the accelerated aging process, embrittlement cracking, hardness or compression resistance Modulus increases and other problems, to achieve the effect of a large operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the embodiment of the present invention, the preparation of an ultra-high temperature resistant and radiation resistant liquid level control cable is as follows:

[0042] 1. Preparation of inorganic composite insulating materials:

[0043] 0.05wt% of gas-phase precipitated silicon oxide particles with a purity of more than 99.999% and an average particle size of 80nm-50μm; 0.08wt% of silicon nitride particles with a purity of more than 99.999% and an average particle size of 80nm-50μm; More than 99.999% of high-purity fused magnesium oxide particles with an average particle size of 30nm-80μm are used for batching.

[0044] Fully mix vapor-phase precipitated silicon oxide and silicon nitride particles and put them into a container for high-temperature firing (900°C×2.5h). After cooling, add the above-mentioned high-purity fused magnesium oxide powder, stir and mix evenly to obtain an inorganic composite insulating material .

[0045] Inorganic composite in...

Embodiment 2

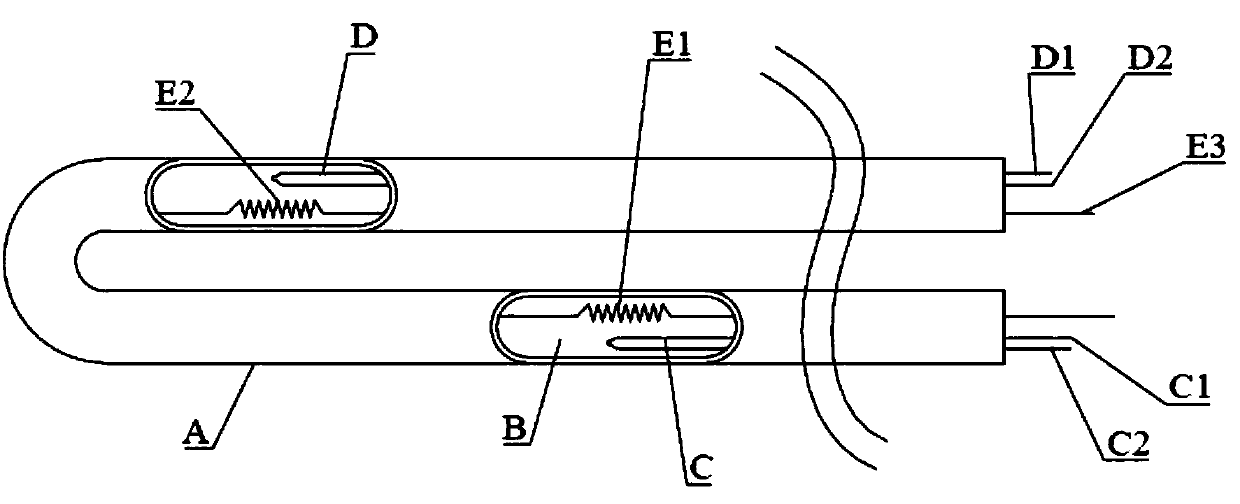

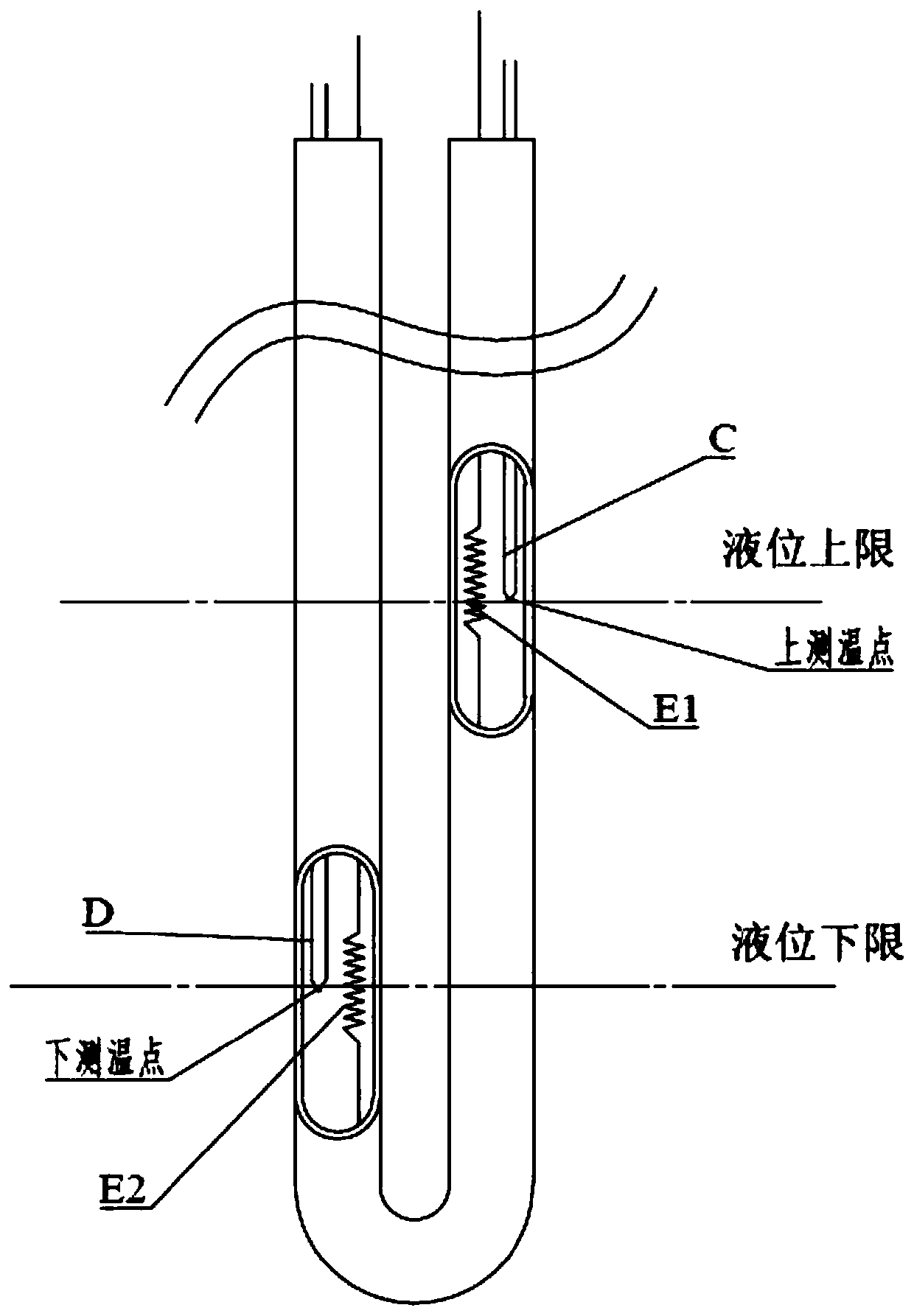

[0058] The ultra-high temperature resistant, radiation-resistant liquid level control cable that adopts embodiment 1 to make is carried out liquid level detection control (referring to figure 2 ), the heating element works at 2.5A, and the heating temperature is about 600°C. When the liquid level in the container is at the upper limit (that is, when the liquid level reaches the upper temperature measuring point), part of the upper limit heating element E1 and the lower limit heating element E1 and the lower limit temperature measuring component D are all immersed in the liquid. Due to the small heat capacity of the heating element, At this time, the temperature at the upper limit temperature measuring point is close to that of the liquid, and the liquid replenishing mechanism is controlled to stop injecting liquid into the container. When the liquid level is lower than the lower limit (that is, when the liquid level is lower than the lower temperature measurement point), the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com