Bending optical fiber array and preparation method thereof

An optical fiber array and bending technology, which is applied in the field of optical fiber communication, can solve the problems of easy damage to the optical fiber array, complicated installation, and great difficulty, and achieve the effects of not being easily damaged or broken, easy to install, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

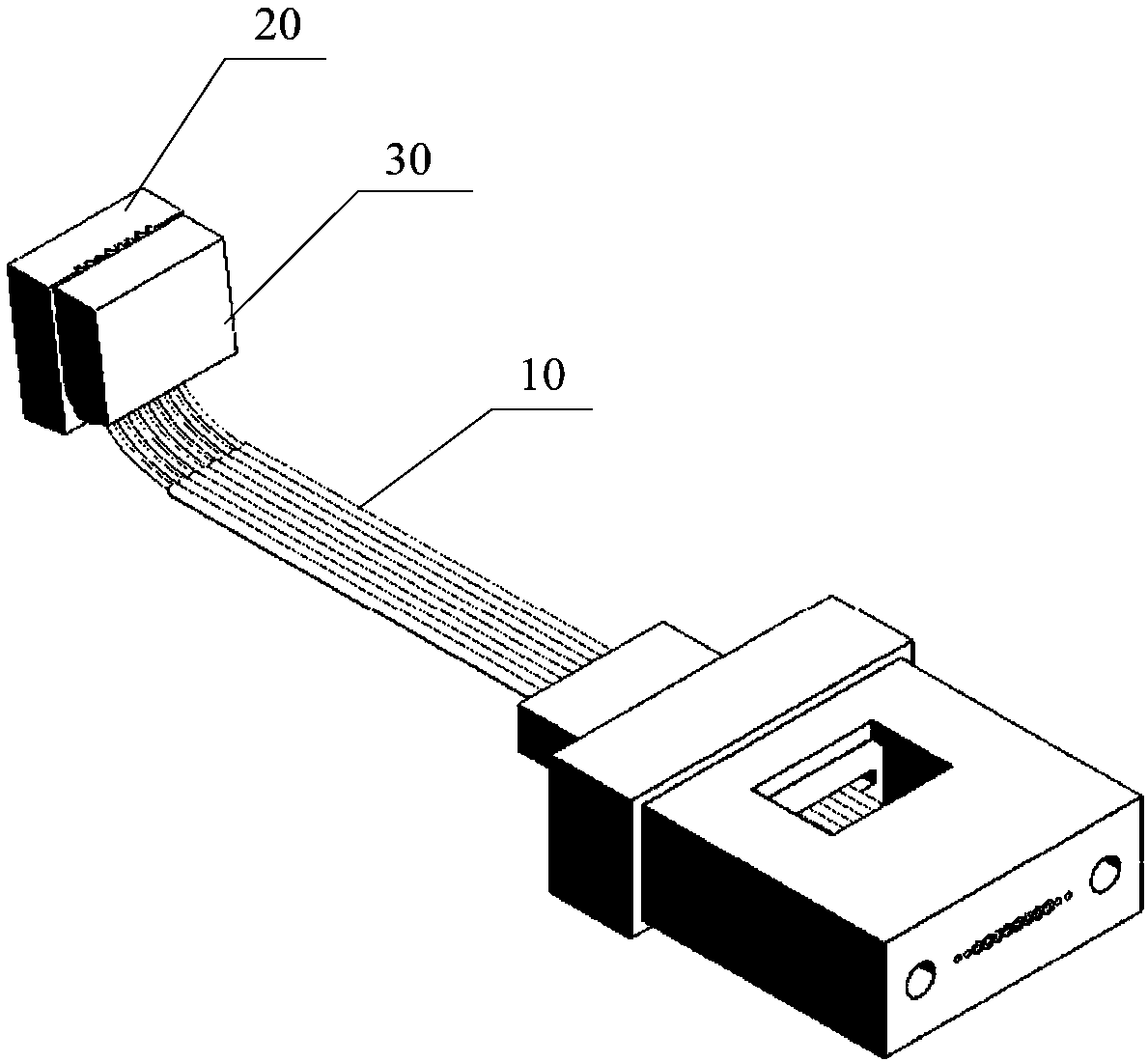

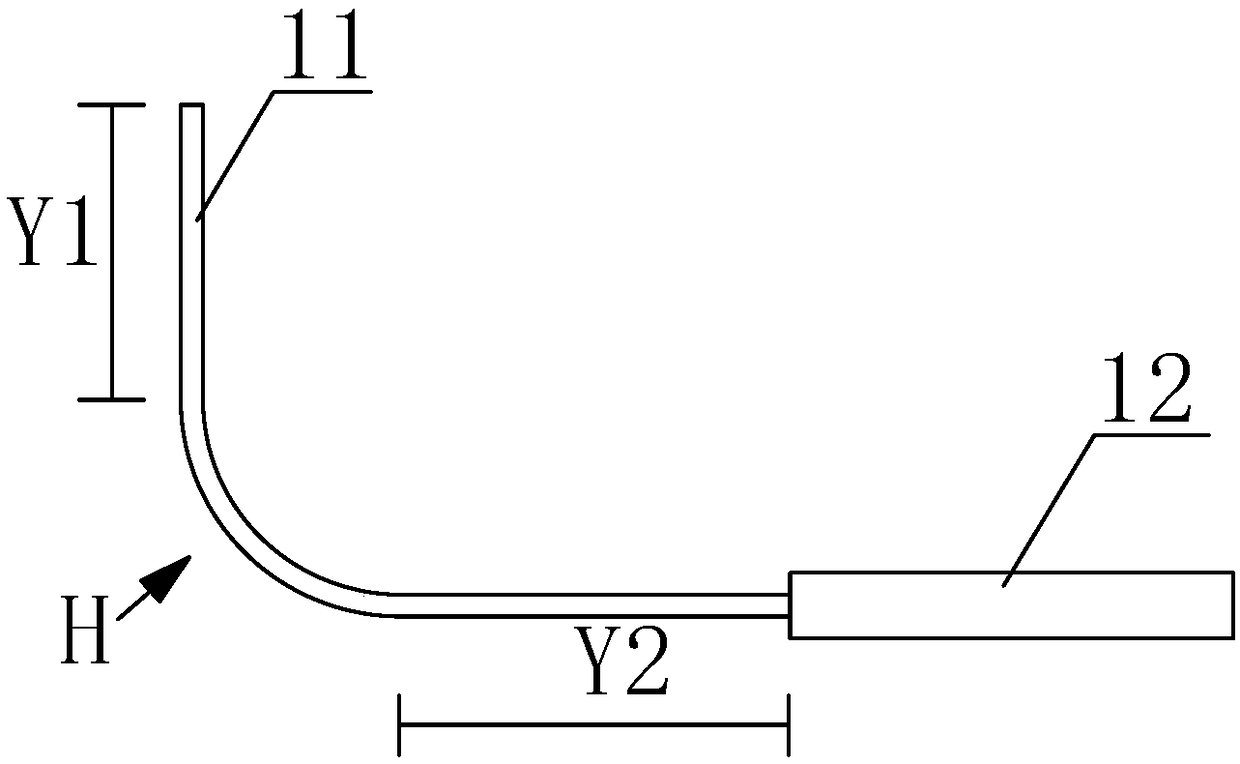

[0027] Such as figure 1 with 2 Shown is a schematic diagram of the structure of the bent optical fiber array of the present invention, the bent optical fiber array includes a cover plate 30, a bottom plate 20 and an optical fiber 10 arranged between the cover plate 30 and the bottom plate 20, wherein the optical fiber 20 is pre-bent Ribbon-shaped multi-channel optical fiber, in the embodiment of the present invention, the number of channels of the ribbon-shaped optical fiber can be selected, and 4 channels, 8 channels, 12 channels, etc. can be selected according to actual needs. The pre-bent ribbon-shaped multi-channel optical fiber includes a ribbon-shaped bare optical fiber portion 11 with the coating layer stripped and a ribbon-shaped optical fiber portion 12 without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com