Swirling afterburner chamber based on outer concave cavity

A technology of afterburner and concave cavity, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of difficult flame propagation and low combustion efficiency, reduce the difficulty of cooling, reduce severe requirements, widen The effect of the flameout limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

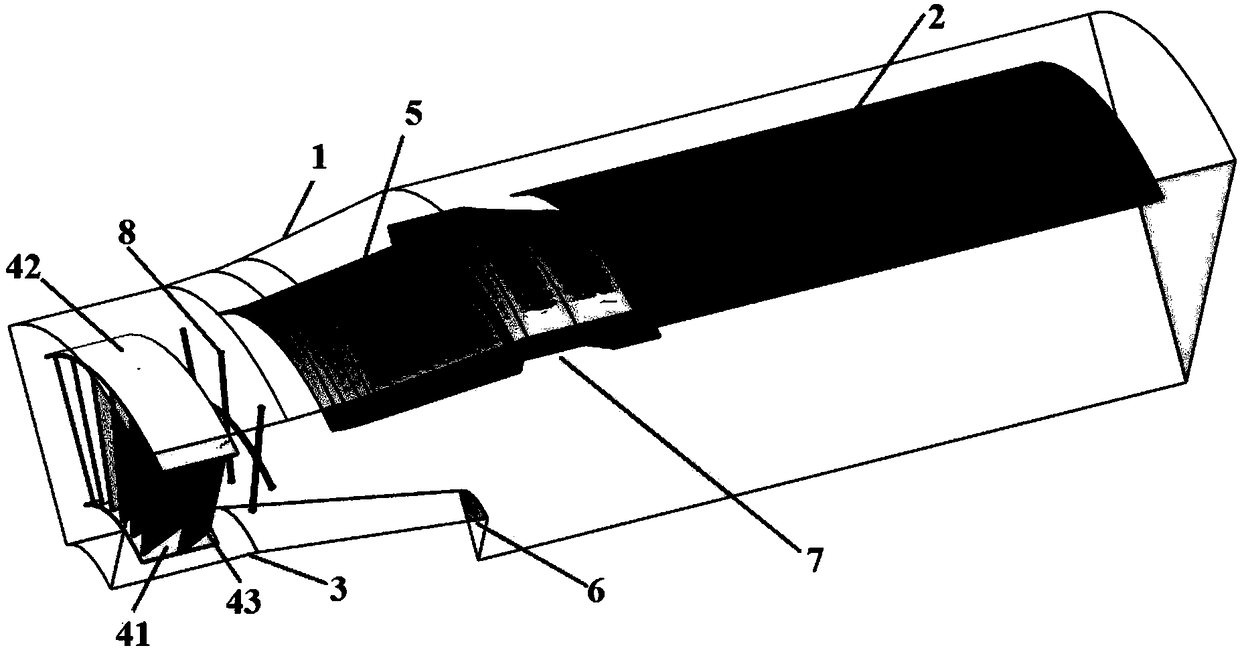

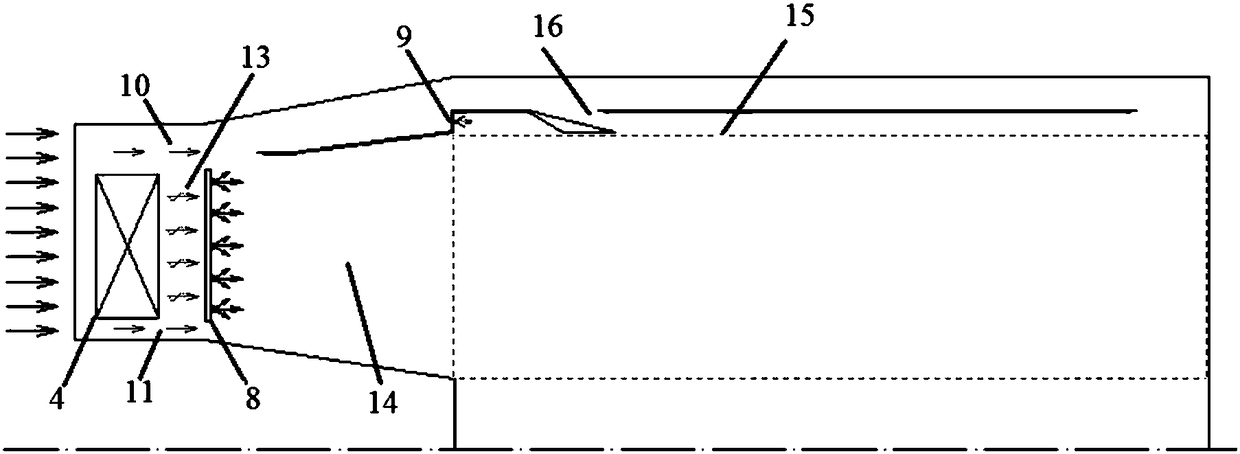

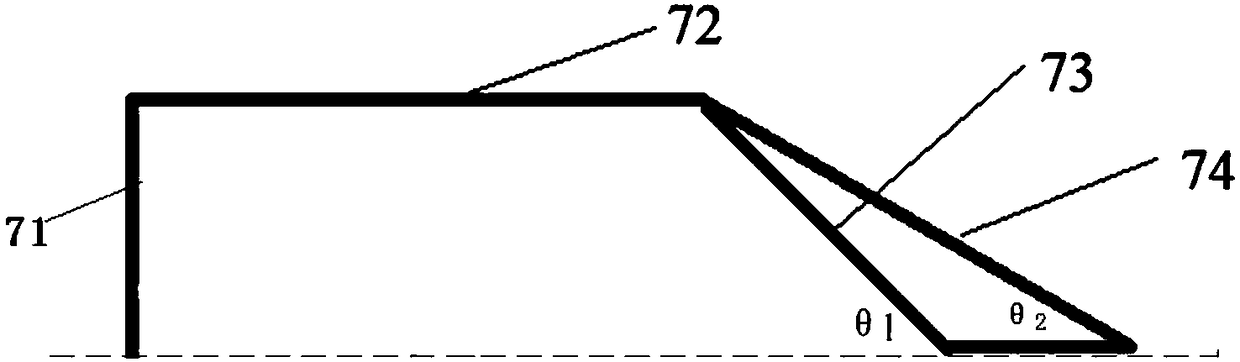

[0026] Example 1: Such as figure 1 with figure 2 As shown, an afterburner includes an outer cylinder assembly, a center body assembly, and an oil circuit assembly; the outer cylinder assembly includes an outer casing 1 and a shock-proof heat shield 2; the center body assembly includes an inner casing 3 , Swirl device 4, splitter plate 5, truncated cone 6, outer cavity flame stabilizer 7; the swirl device includes an inner ring 41, an outer ring 42 and a number of blades 43 connecting the inner ring and the outer ring, the blades are equidistant Arranged, the angle between the blade and the longitudinal section of the swirling device is 25°. The distance between the outer ring and the outer casing is 25% of the inlet diameter of the combustion chamber; the distance between the inner ring and the inner casing of the swirling device is 10% of the inlet diameter of the combustion chamber. The outer cavity flame stabilizer 7 is located at the rear end of the manifold 5, such as im...

Embodiment 2

[0034] Example 2: Using the commercial computational fluid dynamics software Fluent, the numerical simulation of the outer cavity-based swirling afterburner described in Example 1 was carried out, and the relative position between the outer cavity flame stabilizer and the truncated cone was analyzed The effect on flow characteristics and flame propagation. The combustion chamber of Example 1 is arranged in Y0Z0. At this time, the front wall of the outer cavity is aligned with the end of the truncated cone axially, and the flame stabilizer of the outer cavity is moved down 20mm in the radial direction to form Y20Z0 Layout, when the outer cavity flame stabilizer moves back 50mm in the axial direction, it forms a Y0Z50 layout.

[0035] Figure 4 It is a flow diagram of the cold flow field of the combustion chamber of the present invention. Because the splitter plate is at an angle to the axis of the combustion chamber, the incoming flow deflects toward the cavity when moving along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com