Garbage incineration device in oxygen-enriched atmosphere and using method thereof

A waste incineration and atmosphere technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of poor decomposition conditions of dioxin and other harmful substances, high auxiliary fuel consumption, pollution in the incineration process, etc., and achieve volume reduction and the volume of flue gas treatment facilities, improving utilization, reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

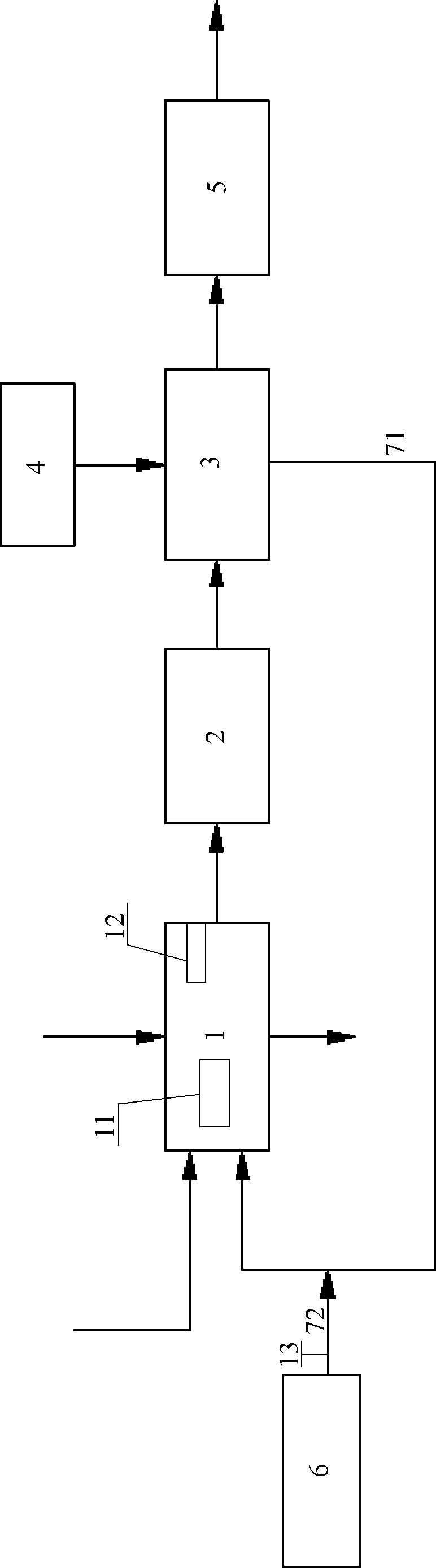

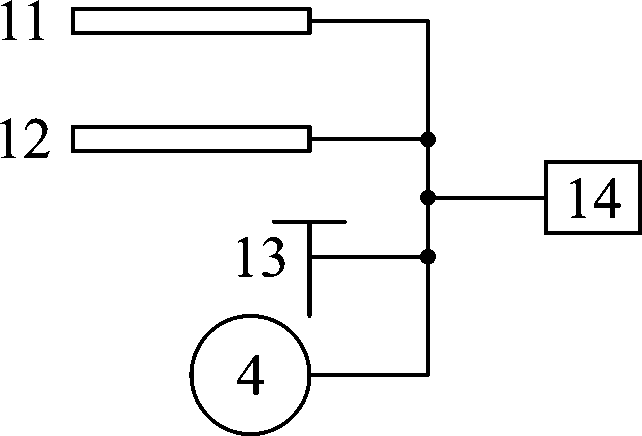

[0030] A garbage incineration device under an oxygen-enriched atmosphere, comprising an incinerator 1, a dust collector 2, a heat exchange device 3, a combustion-supporting fan 4, a purifier 5 and an oxygen generator 6, such as figure 1 and figure 2 As shown, the specific structure is:

[0031] The incinerator 1 is provided with a raw material inlet, a fuel inlet, an oxygen inlet, a flue gas outlet and an incineration outlet, and the heat exchange device 5 is provided with a flue gas pipe and an air pipe;

[0032] The flue gas outlet of the incinerator 1 is connected to the inlet of the flue gas pipe of the heat exchange device 3 through the dust collector 2, the blast port of the combustion-supporting fan 4 is facing the inlet of the air pipe of the heat exchange device 3, and the outlet of the flue gas pipe of the heat exchange device 3 is connected to the purification Device 5, the outlet of the heat exchange device 3 air pipes are connected to the oxygen inlet of the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com