Laser-driven macroscopic liquid flow device and method based on optical fiber

A laser-driven, optical fiber technology, applied in the direction of machine/engine, liquid variable capacity machinery, mechanical equipment, etc., to achieve the effect of improving control accuracy, convenient operation and high flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

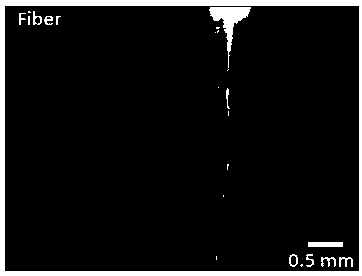

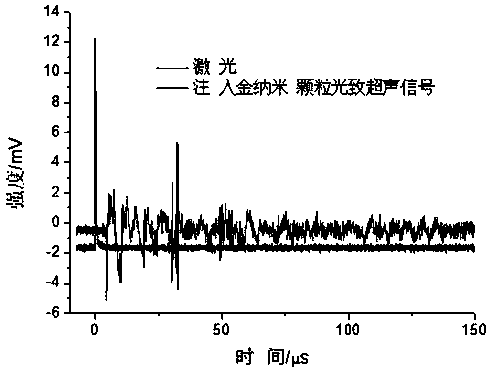

[0045] Further, the optical fiber 3 is a multimode optical fiber with a core diameter of 200 μm and a length of 30 cm. One end of the optical fiber 3 is injected with gold nanoparticles using injection technology, and the injection amount is usually 4×10 16 Au / cm 2 , the injection energy is 60keV.

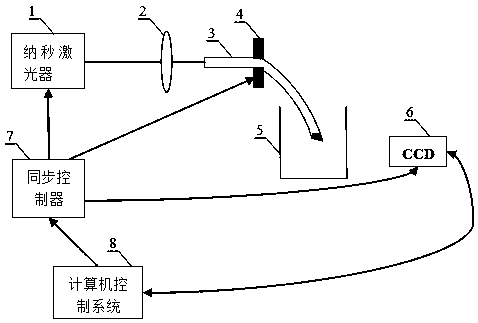

[0046] The nanosecond laser 1 emits laser pulses with a wavelength of 527nm, a pulse width of 150ns, and an average power of 120mW. Lens 2 is a short focus lens with a focus of 50mm. CCD 6 is a photodetector with a pixel size of 1280×1024. CCD 6 is PixelinkPL-B742U type CCD. Synchronous controller 7 adopts 12-bit A / D and D / A conversion inside, and the resolution can reach 0.1%. The computer control system 8 is a general PC.

[0047] according to figure 1 Connect the components in the structure shown, and open the control software of the laser-driven liquid flow device in the computer control system 8. This control software is based on the WINDOWS operating system and uses the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com