Ecotype hydroelectric device based on remote control

A technology for remote control and power generation devices, which is applied in hydropower, hydropower stations, safety devices, etc., and can solve problems such as low safety, unfavorable operation, and large labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

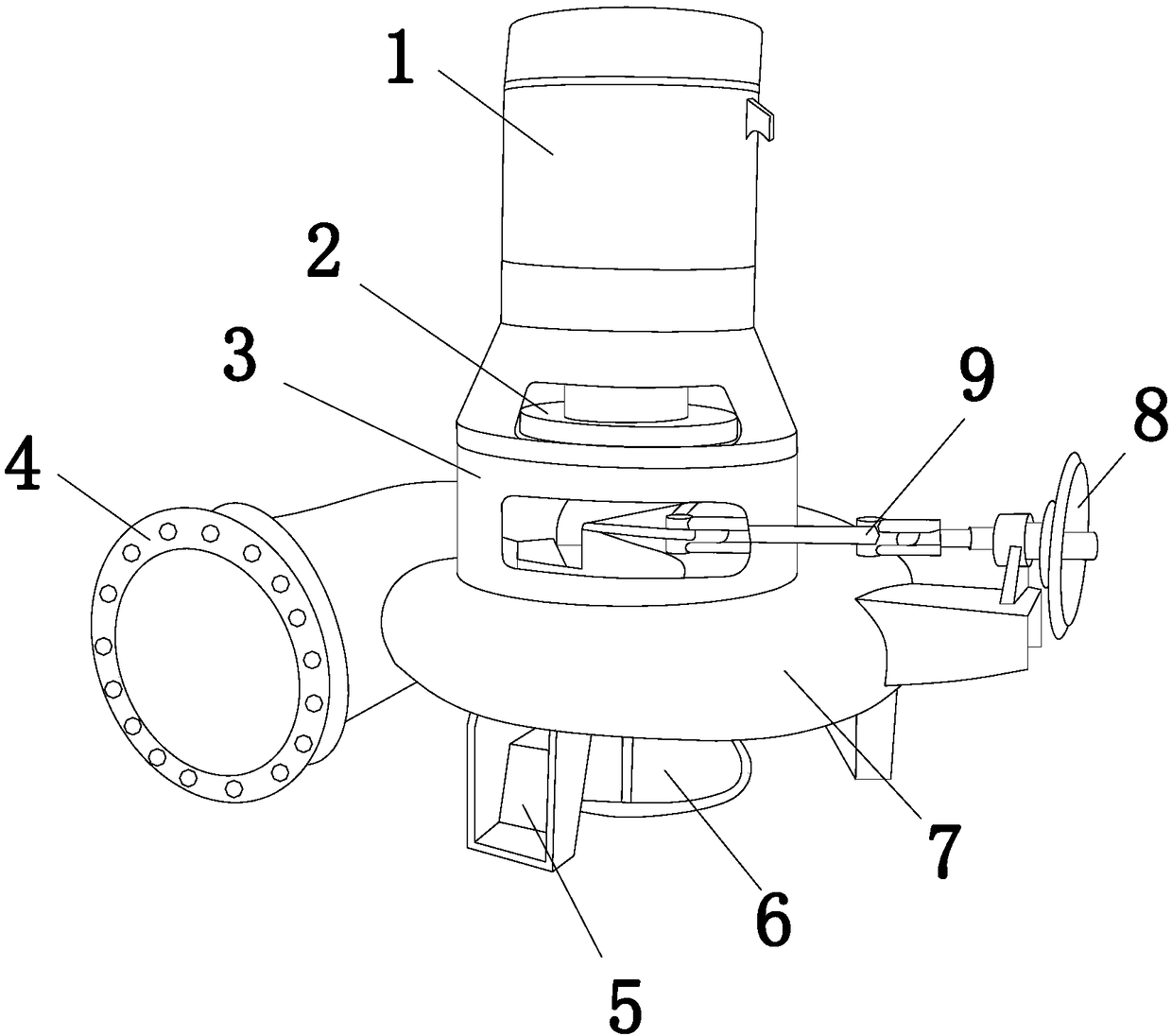

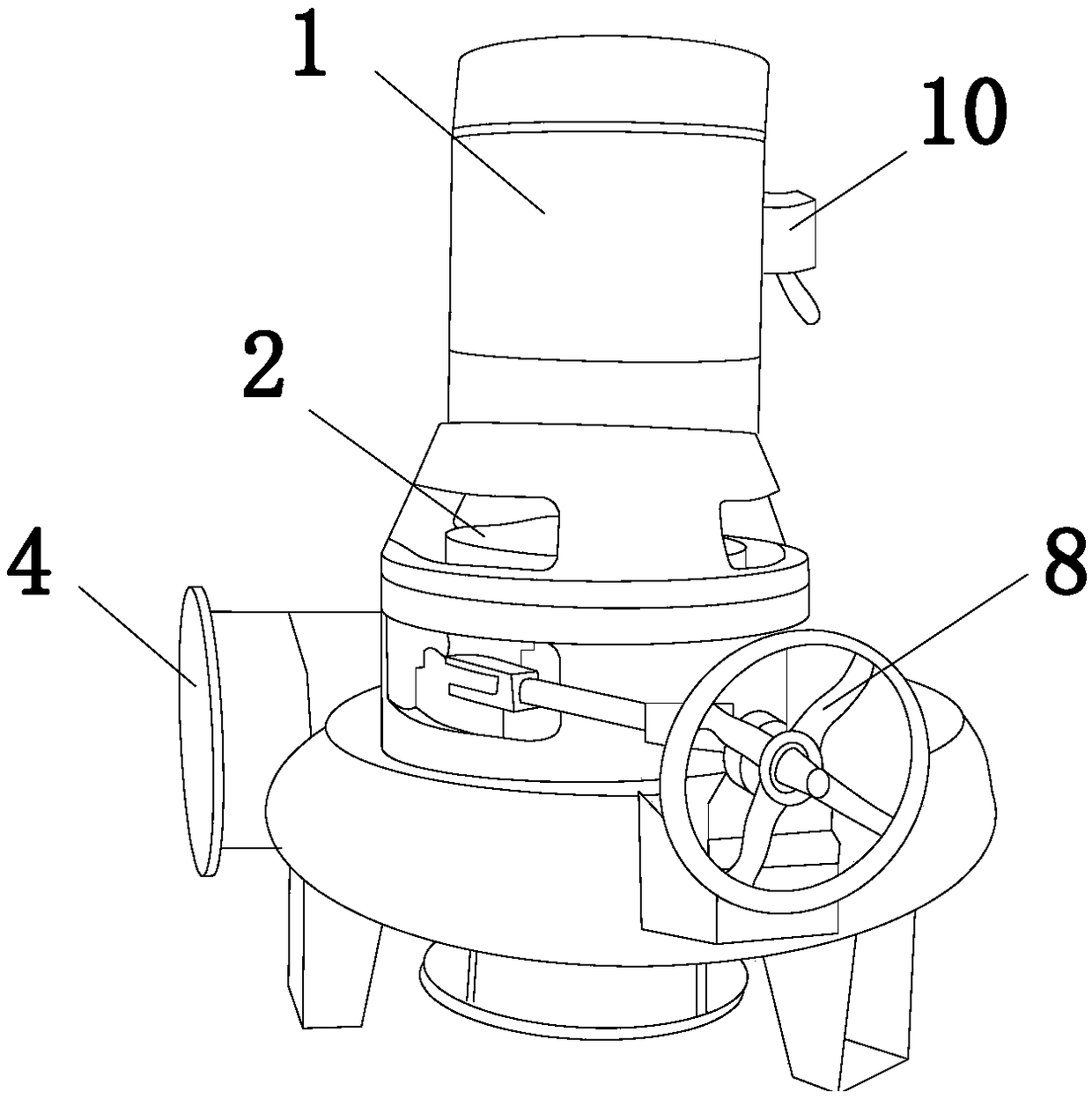

[0031] see Figure 1-Figure 9 , the present invention provides an ecological hydroelectric power generation device based on remote control, its structure includes a generator 1, a mixed-flow impeller 2, an outer cover 3, a water inlet 4, a supporting column foot 5, a water outlet 6, a volute 7, a movable guide Blade adjustment wheel 8, adjustment connecting rod 9, generator junction box 10, turbine water outlet 11, draft pipe 12, the generator 1 is vertically installed on the outer cover 3 and welded into an integrated structure, the inside of the outer cover 3 A mixed-flow impeller 2 is provided and is mechanically connected to the interior of the volute 7. The left end of the volute 7 is provided with a water inlet 4 and connected to an external pipe. The right end of the volute 7 is connected to the adjustment through a welded connection block. The rod 9 is mechanically connected, the movable guide vane adjusting wheel 8 is movably connected to the mixed-flow impeller 2 thr...

Embodiment 2

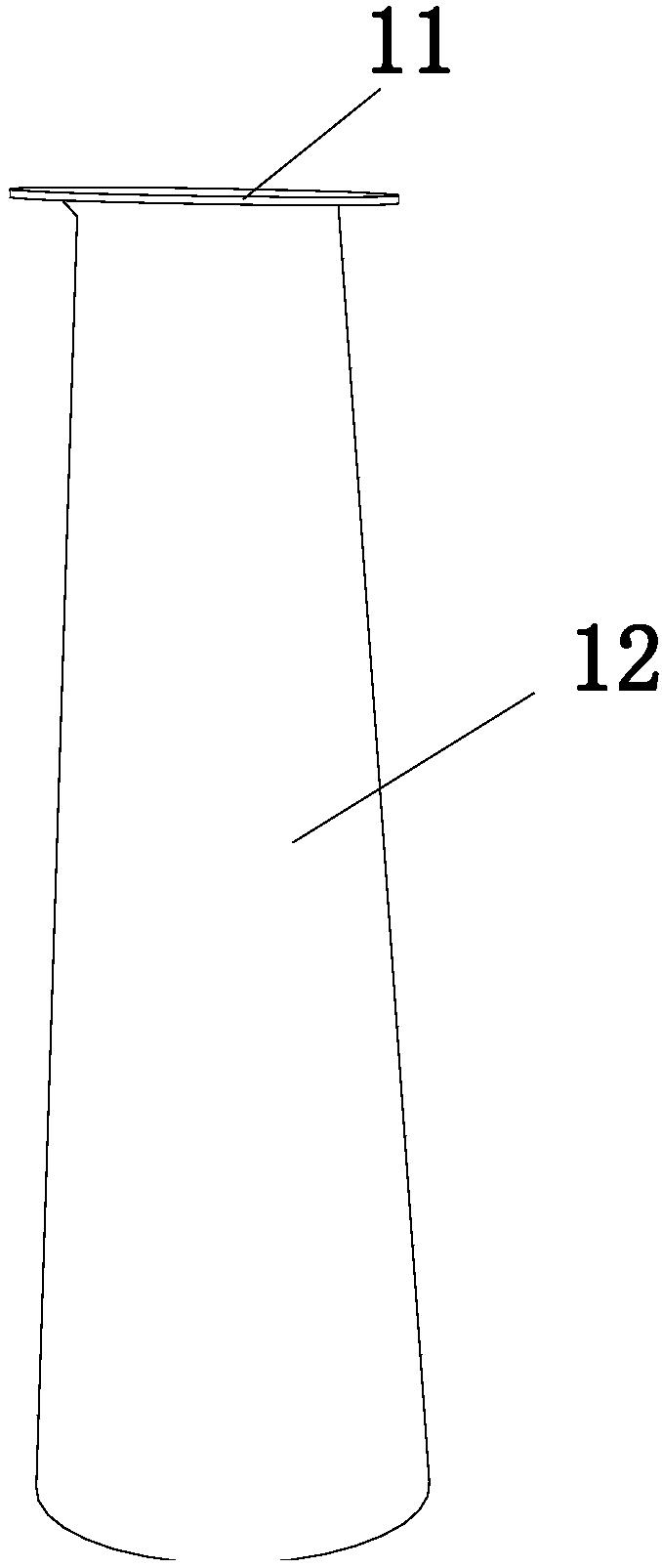

[0034] see Figure 1-Figure 10 , the mixed-flow impeller 2 is composed of a lower ring 201, a blade 202, a water discharge cone 203, and an upper crown 204. The lower ring 201 is integrally formed by the blade 202 and the upper crown 204. The blade 202 is provided with two Above and evenly surrounding two pairs cooperate with each other, the water discharge cone 203 is installed on the center of the blade 202 and on the upper crown 204 .

[0035] The installation of the mixed-flow impeller 2 is first to install the blade 202 under the top cover of the water turbine through a bearing. There is a bottom ring and a draft pipe under the blade 202, and the blade 202 can rotate freely; there is a small gap between the upper crown 204 of the blade 202 and the top cover. It not only ensures free rotation but also prevents water leakage and other problems. Similarly, there is a small gap between the lower ring 201 and the bottom ring of the blade 202, which not only ensures free rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com