Low dilution sublevel caving mining method of steep inclined medium thick orebody

A technology of segmental caving and thick ore body, applied in surface mining, underground mining, special mining, etc., can solve problems such as the impact of mining and blasting, and achieve the effect of reducing large block rate, improving ore recovery conditions, and improving mining economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

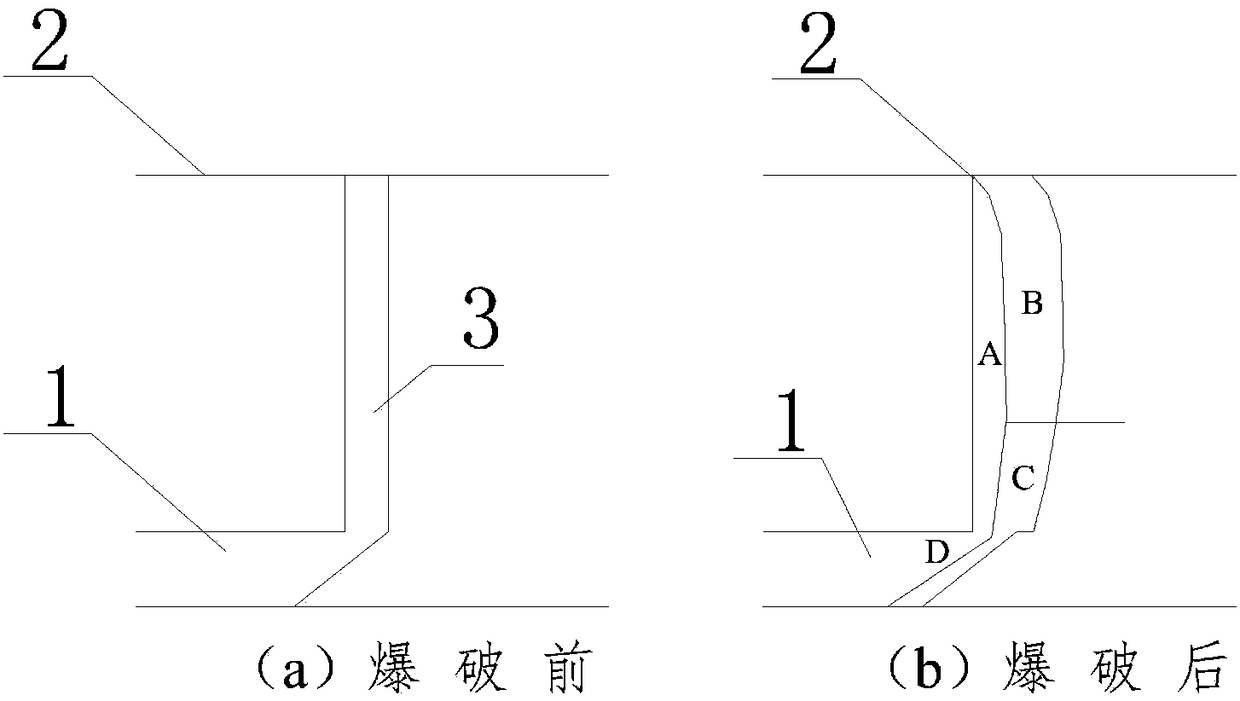

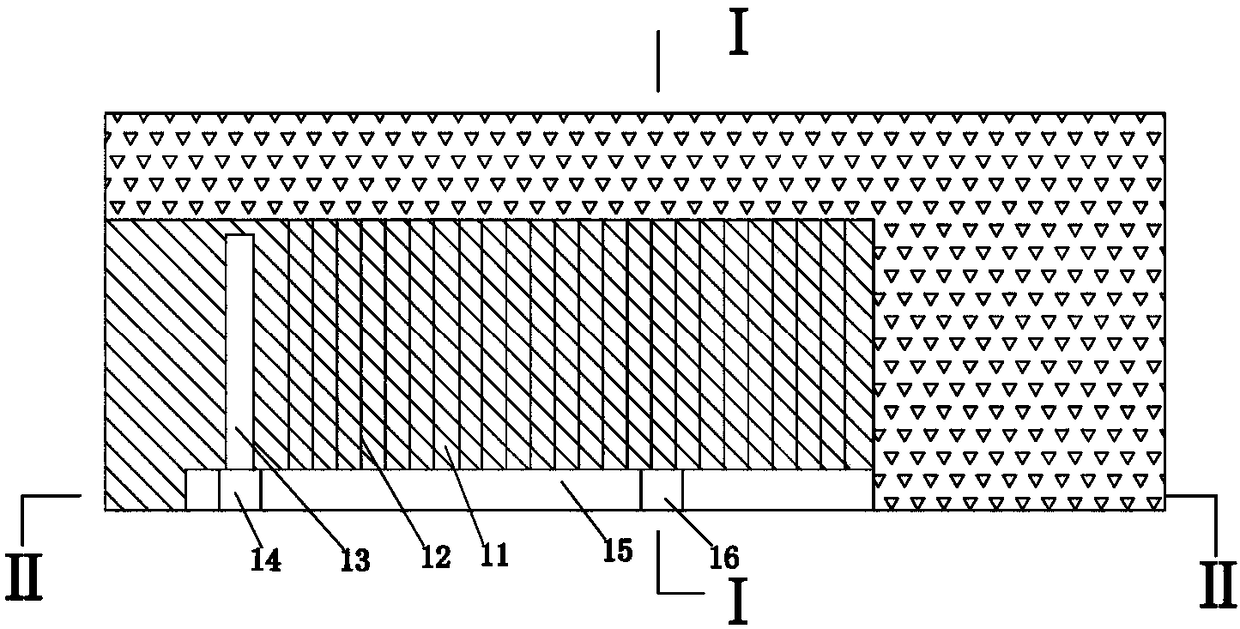

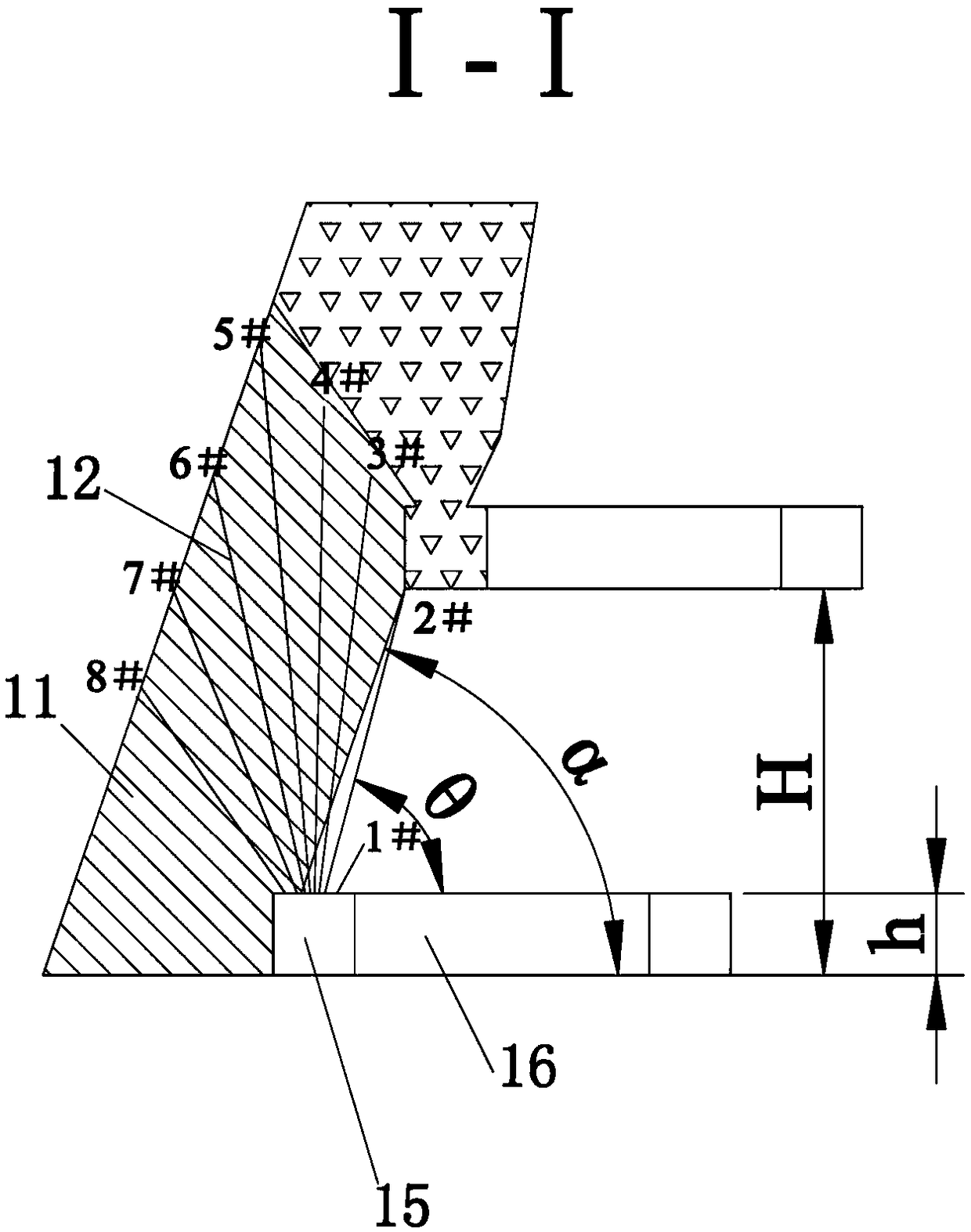

[0025] Such as Figure 2-4 As shown, a low-loss segmental caving mining method of a steeply inclined medium-thick ore body of the present invention includes segmental mining of the ore body in the stage from top to bottom, arranging footwall transport roadways in segments, ore drawing Chute 17 and roadway 15 are characterized in that: comprise the following steps:

[0026] (1) Determine the position of the recovery route along the vein

[0027] Calculate the horizontal distance between the central line of the 16 roof of the mining approach along the vein and the footwall of the ore body according to the formula, and excavate the mining approach along the vein,

[0028] d=(H-h)(cotα-cotθ)

[0029] In the formula, d-horizontal distance from the center line of the roof of the approach to the footwall of the ore body, m, H-segment height, m; h-height of the mining approach, m; α-inclination angle of the ore body footwall, °, θ-caving Apparent discharge angle of ore, °;

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com