Steel pipe restraining concrete joint structure, corresponding truss structure and construction method

A technology for constraining concrete and node structures, applied in building construction, erection/assembly of bridges, bridge parts, etc., can solve the problems of node failure, easy cracking, fatigue cracks, loss of bearing capacity of truss structures, etc. Reliable mechanical properties and the effect of increasing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

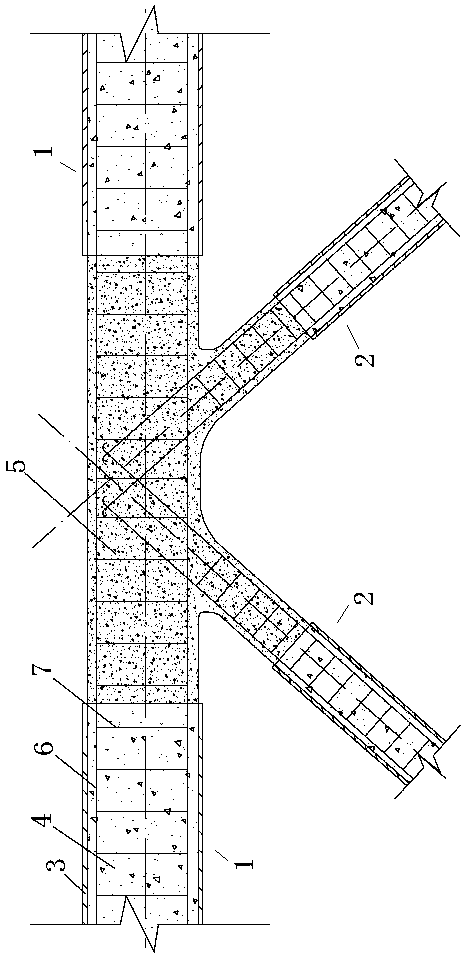

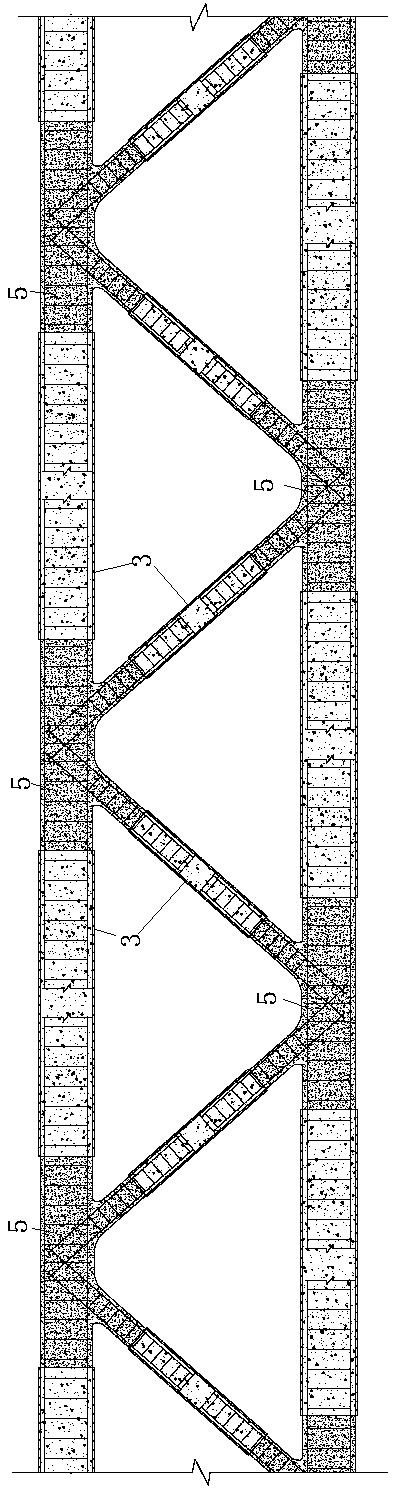

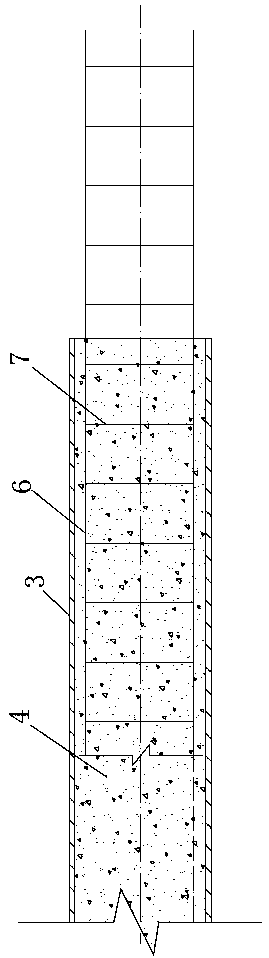

[0023] Such as Figure 1-7 As shown, a steel pipe confined concrete node structure includes a chord 1 and a web 2, and both the chord and the web include a steel pipe 3 and a steel grid frame, and one end of the steel grid frame is pre-embedded by ordinary concrete 4 Both the inside and the other end of the steel pipe extend out of the steel pipe, and the chords and webs are connected to each other through an external steel grid frame, and ultra-high performance concrete 5 is poured at the connection.

[0024] In the embodiment of the present invention, the reinforced grid includes several longitudinal bars 6, and several longitudinal bars are bound together by several stirrups 7, and the joints are encrypted with longitudinal bars and stirrups to reduce the UH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com