Waterborne thermosensitive polyurethane and preparation method thereof

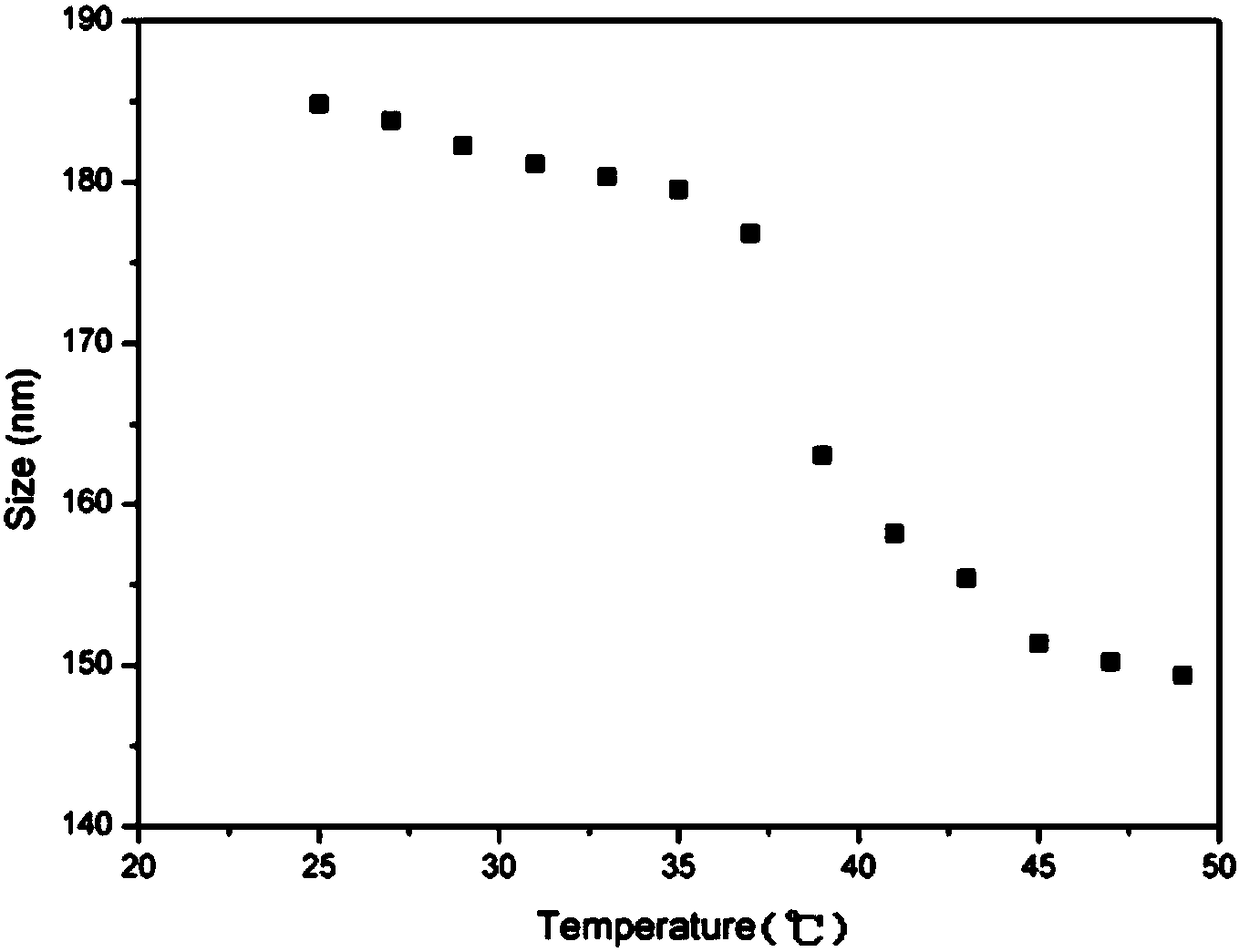

A polyurethane and temperature-sensitive technology, applied in the field of water-based temperature-sensitive polyurethane and its preparation, can solve the problems of high production cost, unsatisfactory, complex synthesis method, etc., and achieves large particle size, viscosity and wear resistance. Satisfying, temperature sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of linear thermosensitive polyurethane, its preparation method is as follows:

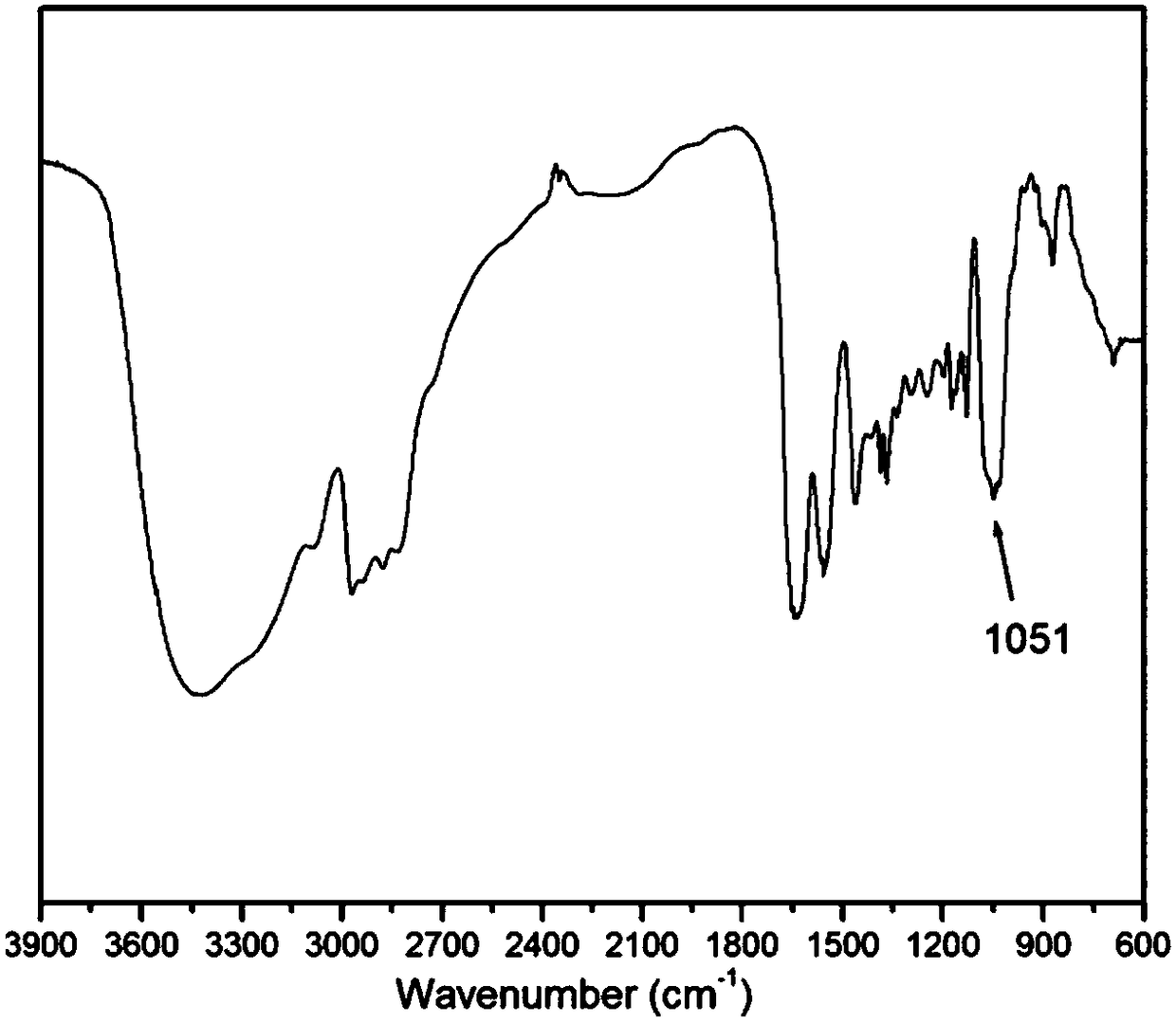

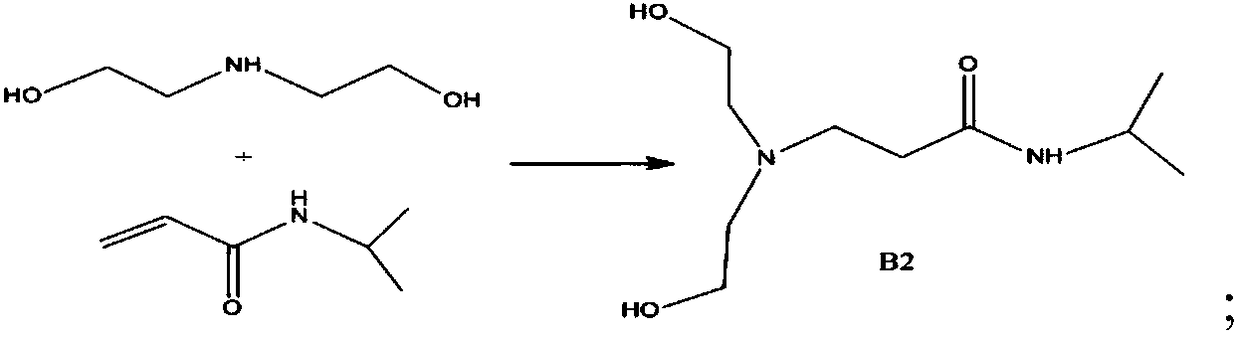

[0029] S1. Add 0.02mol N-isopropylacrylamide and 0.024mol diethanolamine to a 100mL two-necked bottle, and stir magnetically for 48 hours under nitrogen gas at 70°C to obtain the thermosensitive monomer B2 containing dihydroxy .

[0030] S2. The polycarbonate diol (PCDL-1000, indicating a molecular weight of 1000) was dehydrated under a vacuum degree of -0.095 MPa and 130° C. for 2 hours, and set aside. Add 0.006mol PCDL-1000, 0.004mol dimethylolpropionic acid and 40mL acetone after dehydration into a 250mL four-neck flask equipped with a condensing reflux device, a mechanical stirrer and nitrogen gas, and at 75°C Stir well, then add 0.012mol of toluene diisocyanate and 0.0005mol of catalyst dibutyltin dilaurate, react at 75°C for 3 hours, add 0.004mol of temperature-sensitive monomer B2 synthesized by S1, continue to react at 75°C for 2h, then add 0.004mol of tributyltin dilaurate ...

Embodiment 2

[0032] A kind of linear thermosensitive polyurethane, its preparation method is as follows:

[0033] S1. Add 0.02mol N-isopropylacrylamide and 0.022mol diethanolamine to a 100mL two-necked bottle, and stir it magnetically for 48 hours under nitrogen gas at 65°C to obtain the thermosensitive monomer B2 containing dihydroxy .

[0034] S2. Remove water from the polycarbonate diol (PCDL-500) at a vacuum degree of -0.095 MPa and 130° C. for 2 hours, and set aside. Add 0.005mol PCDL-500, 0.004mol dimethylolpropionic acid and 50mL acetone after dehydration into a 250mL four-neck flask equipped with a condensing reflux device, a mechanical stirrer and nitrogen gas, and at 70°C Stir well, then add 0.014mol toluene diisocyanate and 0.0006mol catalyst dibutyltin dilaurate, react at 70°C for 4h, add 0.004mol of temperature-sensitive monomer B2 synthesized by S1, continue to react at 70°C for 3h, then add 0.004mol Ethylamine and 180mL deionized water, and finally remove acetone by rotary...

Embodiment 3

[0036] A kind of linear thermosensitive polyurethane, its preparation method is as follows:

[0037] S1. Add 0.02mol N-isopropylacrylamide and 0.026mol diethanolamine to a 100mL two-necked bottle, and stir it magnetically for 48 hours under nitrogen gas at 75°C to obtain the thermosensitive monomer B2 containing dihydroxy .

[0038] S2. Remove water from the polycarbonate diol (PCDL-2000) at a vacuum degree of -0.095 MPa and 130° C. for 2 hours, and set aside. Add 0.007mol PCDL-2000, 0.004mol dimethylolpropionic acid and 60mL acetone after dehydration into a 250mL four-necked flask equipped with a condensing reflux device, a mechanical stirrer, and nitrogen gas. Stir evenly, then add 0.016mol toluene diisocyanate and 0.0006mol catalyst dibutyltin dilaurate, react at 80°C for 3 hours, add 0.004moL of temperature-sensitive monomer B2 synthesized by S1, continue to react at 80°C for 2h, then add 0.004mol of tributyltin dilaurate Ethylamine and 200mL deionized water, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com