Method for continuously producing active magnesium oxide and recovering carbon dioxide by using microwave heating magnesite

A technology of activated magnesium oxide and carbon dioxide, applied in chemical instruments and methods, products, inorganic chemistry, etc., can solve the problems of low activation, slow heating speed, serious crystallization of magnesium oxide, etc., and achieve good airtightness and high temperature control accuracy , high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

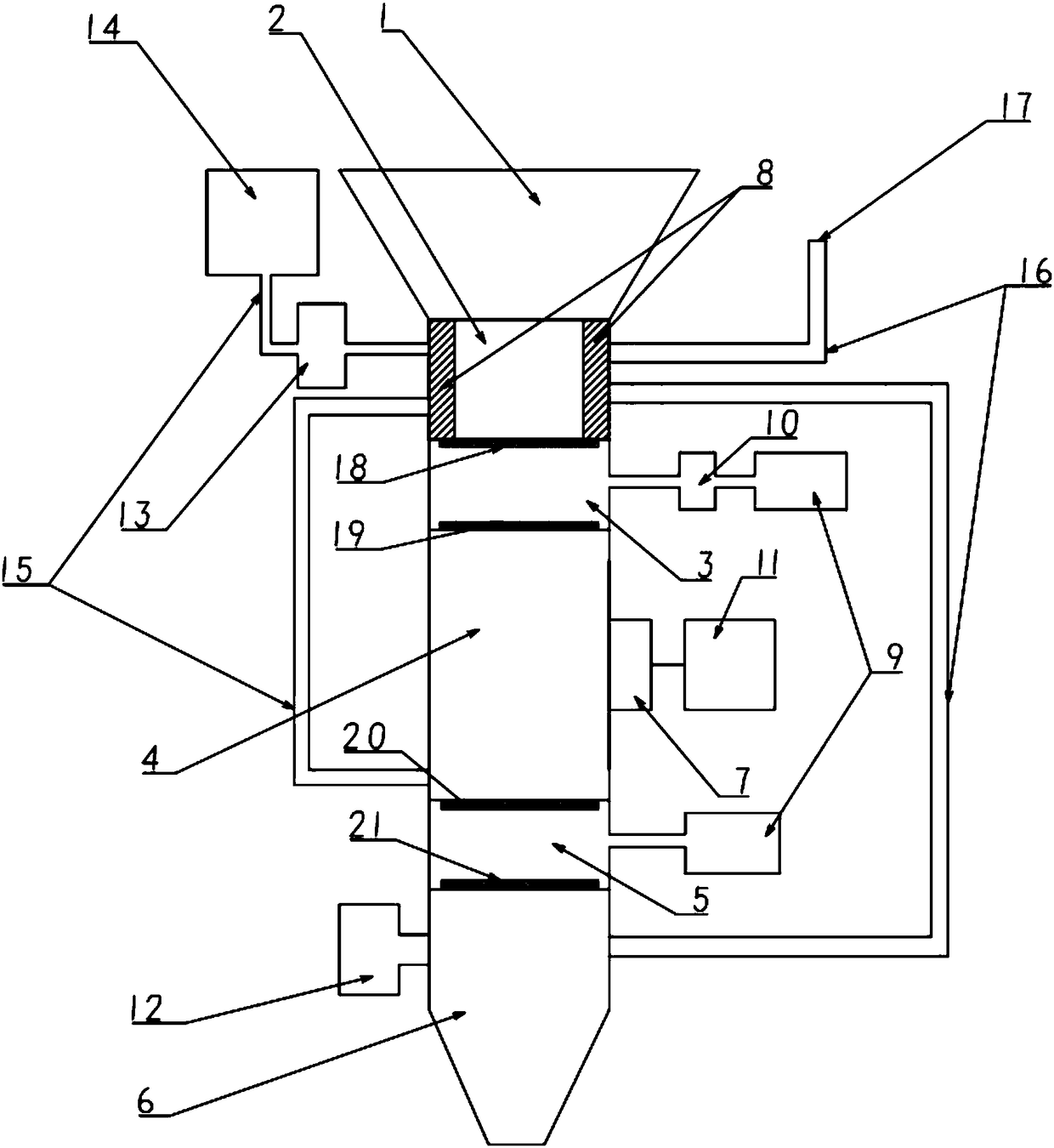

[0045] Such as figure 1 As shown, the present invention utilizes microwave heating magnesite to continuously produce active magnesia and reclaim the production device of carbon dioxide, consists of a weighing distribution bin 1, a preheating chamber 2, a feeding vacuum chamber 3, an exhaust chamber 4, and a discharging vacuum chamber 5 , cooling collection chamber 6, air heat exchanger 8, vacuum pump 9, cooling device 10, blowing cooling system 12, air-water heat exchanger 13, carbon dioxide collection system 14, various sensors and programmable controller PLC and various execution Institutional composition, the specific structure is as follows:

[0046] The top of the preheating chamber 2 is provided with a weighing and distributing bin 1, the bottom of the preheating chamber 2 communicates with the feeding vacuum chamber 3 through the feeding vacuum chamber entrance door 18, and the bottom of the feeding vacuum chamber 3 connects with the exhaust chamber through the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com