Engineering machinery cab with electromagnetic shielding function

A technology of engineering machinery and electromagnetic shielding, applied in the direction of magnetic/electric field shielding, shielding materials, electrical components, etc., can solve problems such as information distortion, endangering the health of operators, and control failure, and achieve reliable performance, easy implementation, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

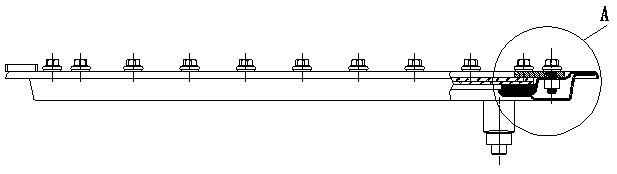

[0036] 1. The electrical connection structure between the shielding glass and the movable window frame:

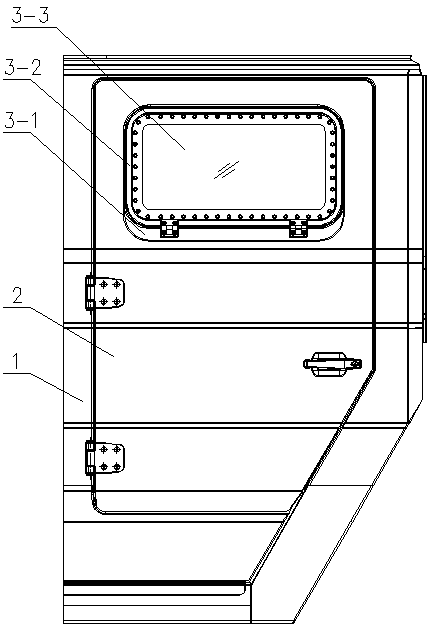

[0037] Such as figure 1 As shown, the engineering machinery cab includes a vehicle body 1, a car door 2 is set on the car body 1, a fixed window frame 3-1 is set on the car door 2, and the movable window frame 3-2 can be matched with the fixed window frame 3-1 by hinges and other connectors. 1, a shielding glass 3-3 is set in the movable window frame 3-2.

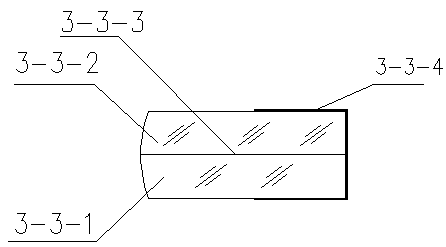

[0038] Such as figure 2 As shown, the shielding glass 3-3 is composed of an inner layer glass 3-3-1, an outer layer glass 3-3-2 and a wire mesh 3-3-3 clamped between the inner layer glass and the outer layer glass. Copper foil 3-3-4 is wrapped around the inner and outer layers of glass and the wire mesh, and the copper foil 3-3-4 is electrically connected to the wire mesh 3-3-3.

[0039] The light transmittance of the above shielding glass 3-3 is ≥70%, and the shielding efficiency is ≥20dB.

[0040] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com