Die-cutting machine and die-cutting method thereof

A die-cutting machine and die-cutting technology, applied in metal processing, etc., can solve problems such as difficult disassembly, achieve high degree of automation, beautiful form, and improve die-cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

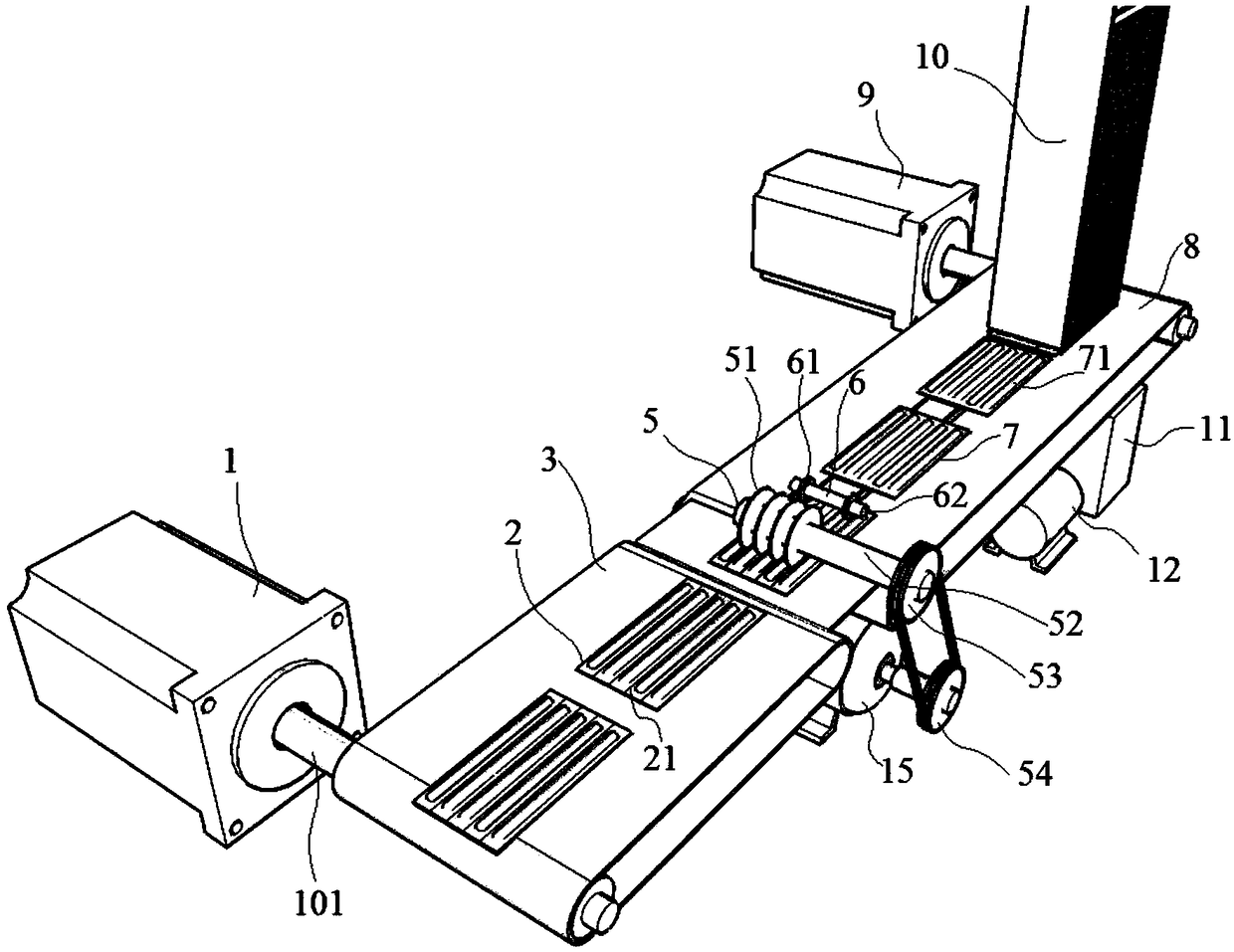

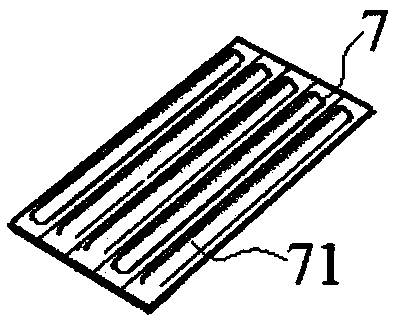

[0042] like figure 1 and figure 2 shown, with figure 1 A die-cutting machine includes a die-cutting template 4 and a die-cutting knife 5, the die-cutting template 4 is evenly distributed with several grooves, and the die-cutting knife 5 includes a die-cutting knife shaft 52 die-cutting blades 51 equal in number to the grooves, wherein the die-cutting blades 51 are located in the grooves. The die-cutting knife 5 rotates in the groove, and when the product group 7 before die-cutting arrives on the die-cutting template 4, the die-cutting knife 5 rotates to drive the product group 7 before die-cutting to move on the die-cutting template 4, and the die-cutting knife 5 and the groove, between the adjacent products 71 on the product group 7 before die-cutting, the die-cutting blade 51 cuts a dividing dotted line 21 to form the product group 2 after die-cutting. The distance between adjacent products 71 is equal to the distance between adjacent grooves and the distance between adj...

Embodiment 2

[0044] like figure 1 and figure 2 As shown, a die-cutting machine, on the basis of Embodiment 1, also includes a feeding conveyor belt 8, and the feeding conveyor belt 8 is located on the entrance side of the die-cutting template 4 and is adjacent to the die-cutting template 4. One end of the feed conveyor belt 8 is connected with the output shaft of the feed conveyor belt motor 9, and the output shaft and the driven shaft of the feed conveyor belt motor 9 are all fixed on the side plate by bearings. The other end of the feeding conveyor belt 8 is adjacent to the die-cutting template 4 and is connected with a driven shaft. The output shaft of the feeding conveyor belt motor 9 rotates to drive the feeding conveyor belt 8 to drive forward. The product group 7 before die-cutting includes a plurality of products 71 arranged side by side, and the products 71 are strip-shaped, and the distances between adjacent products 71 are equal. On the product group 2 after die-cutting, ther...

Embodiment 3

[0046] like figure 1 As shown, a die-cutting machine, on the basis of Embodiment 1 or 2, also includes a guide device 6, and the guide device 6 includes a material receiving pressure wheel 61 and a material receiving pressure shaft 62, and the material receiving pressure shaft 62 Two ends of each are provided with a receiving pressure wheel 61, and the guide device 6 is located above the end adjacent to the feeding conveyor belt 8 and the die-cutting template 4. The distance between the guide device 6 and the die-cutting blade 51 is less than the length of the product group 7 before die-cutting, which is convenient to play an effective guiding role. If the distance is too long, the product group 7 before the die-cutting does not reach the die-cutting blade 51. , there is still a possibility that a section may be stuck, blocked or the position of the product group 7 before die-cutting may move, so that the product group 7 before die-cutting cannot reach the die-cutting template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com