Diatom-prawn compound aquaculture system and process

A culture system and a culture system technology, applied in the field of diatom-shrimp compound culture system, can solve the problems of complex microalgae culture process, harm to shrimp healthy growth, culture failure, etc. The effect of inhibiting the growth of Vibrio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

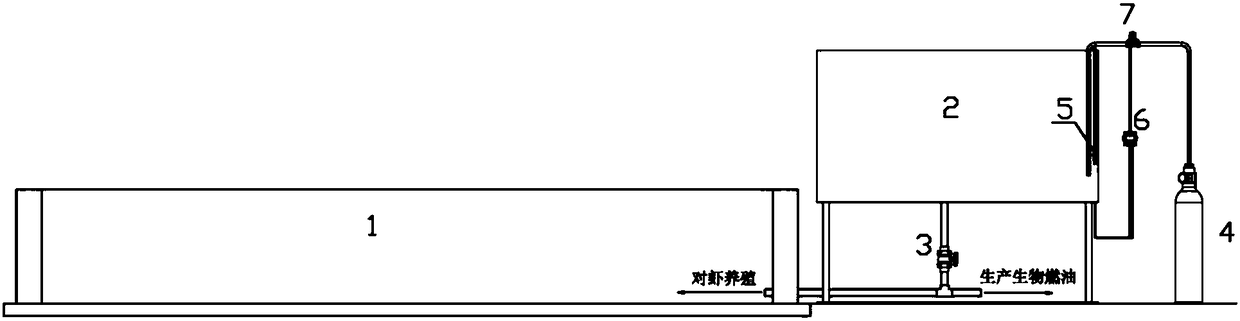

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] Usable area 21m 2 Prawns are cultivated in a rectangular cement pond with a depth of 90cm, and a 1.5kW Roots blower is used to aerate and increase oxygen 24 hours a day.

[0029] Before the system puts shrimp fry, within 1m 3 Add the seawater sterilized by sand filtration into the diatom cultivation tank, and add the nutrient salt, the specific formula is 1m 3 Add 26.5g of urea, 5g of potassium dihydrogen phosphate, 30g of sodium metasilicate, 2g of ferric oxide to seawater, and wait until the density of diatom cells proliferates to 1×10 5 After ind / ml, discharge 70-80% of the diatom water in the diatom cultivation tank every day, and then add nutrient salts into the diatom tank according to the above formula. Part of the diatom water discharged is used to change the water in the shrimp pond, and the rest is used for Extraction to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com