Assembled integral type energy-consuming framework wallboard system and construction method

A monolithic, wall panel technology, applied to walls, protective buildings/shelters, buildings, etc., can solve problems such as wall damage, and achieve the effects of preventing rigid damage, structural stability, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

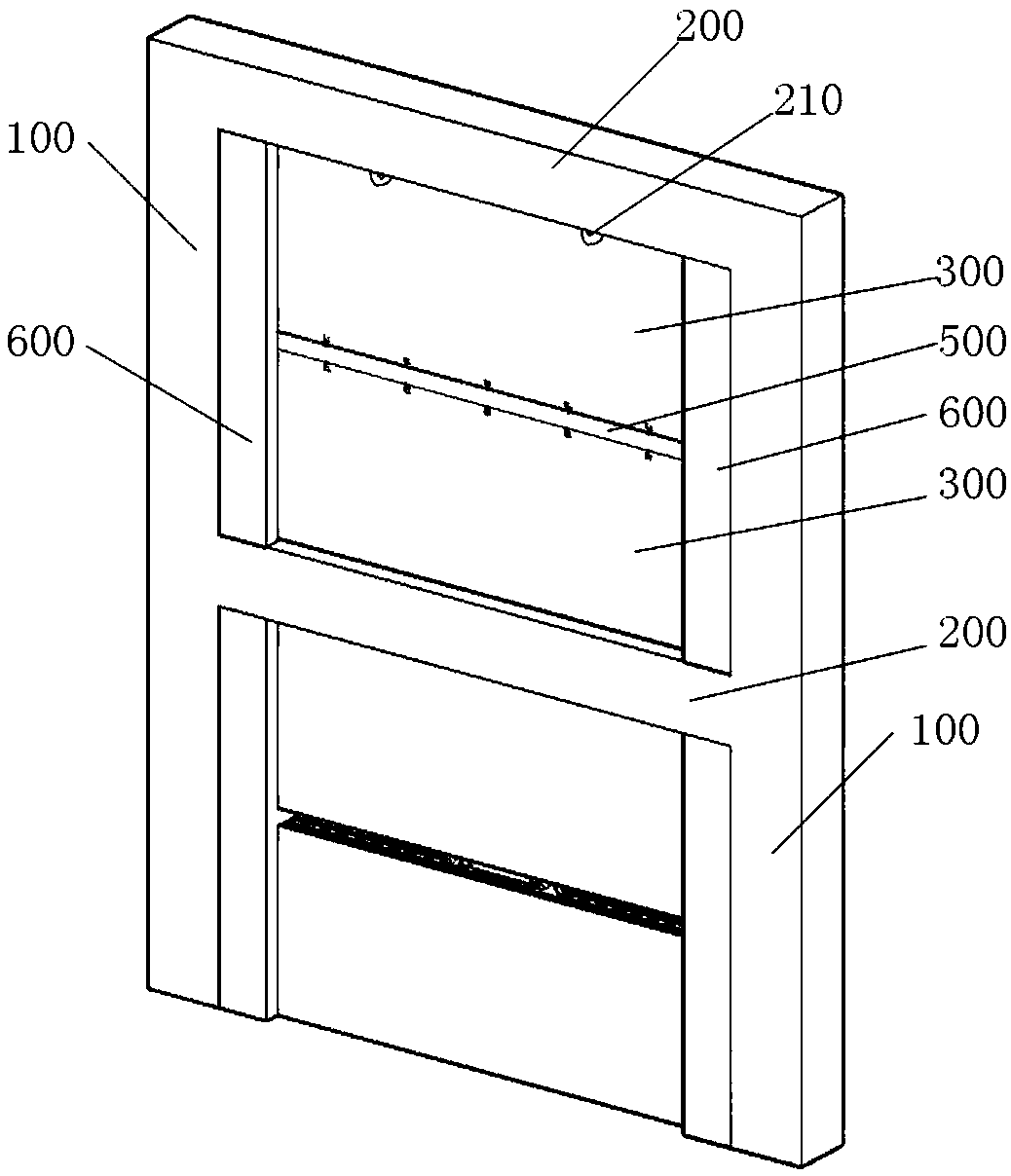

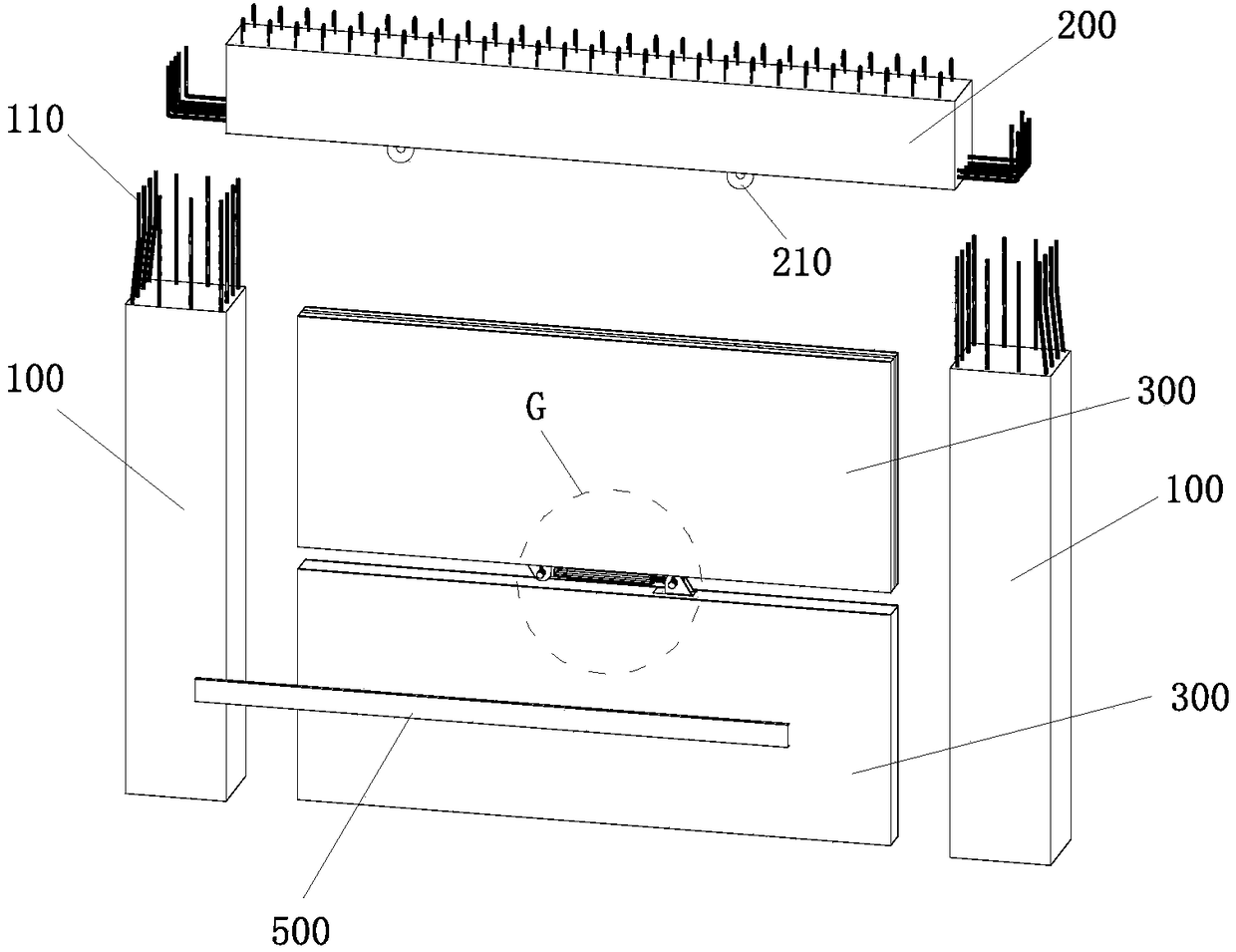

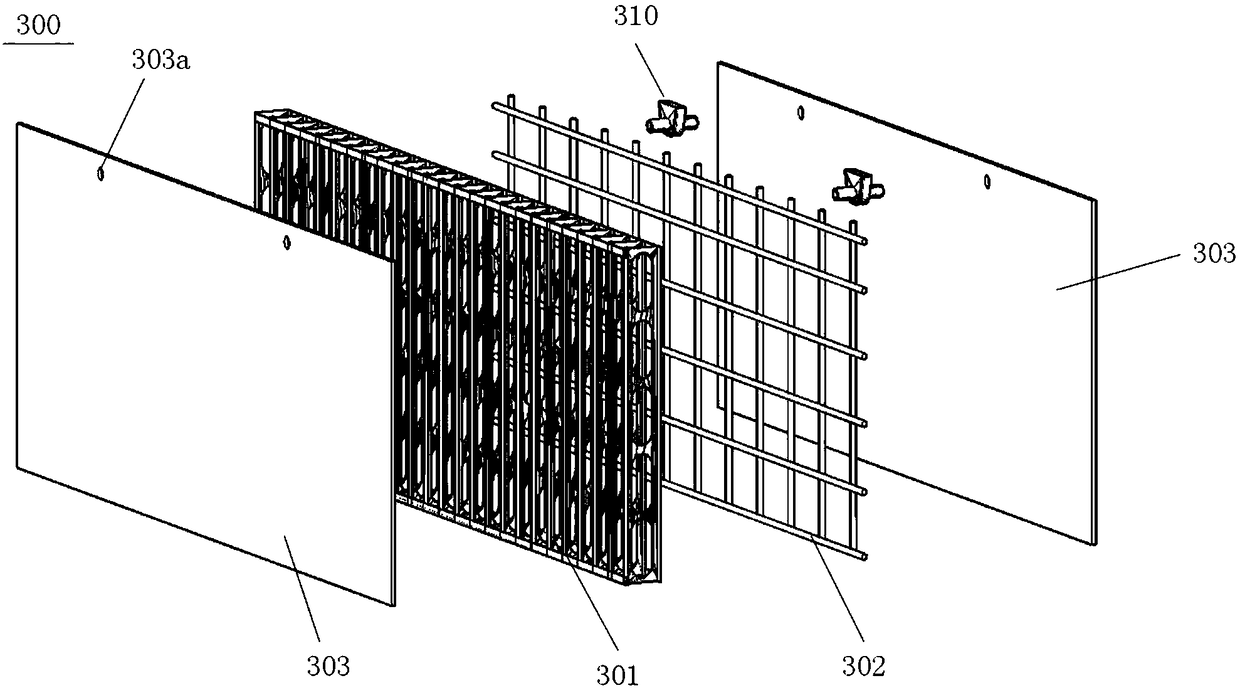

[0047] see figure 1 with figure 2 As shown, the assembled integrated energy-dissipating frame wall panel system provided by the present invention includes prefabricated columns 100 , prefabricated beams 200 , energy-dissipating wall panels 300 , viscous dampers 400 and cover plates 500 .

[0048] Among them, such as figure 2As shown, the prefabricated columns 100 are vertically arranged at intervals in parallel, the prefabricated beams 200 span the prefabricated columns 100 , and the joints of the prefabricated beams 200 and the prefabricated columns 100 are integrally formed by cast-in-place concrete. Preferably, the top of the longitudinal reinforcement of the prefabricated column 100 is connected with a sleeve 110, and the gap between the sleeve 110 and the longitudinal reinforcement of the prefabricated column 100 is filled with grouting liquid. Grouting of the sleeve 110 is a common technique and will not be repeated here. Wherein, the prefabricated beam 200 and the p...

Embodiment 2

[0058] The present invention also provides a construction method for assembling the integral energy-dissipating frame wall panel system in Embodiment 1, which includes the following steps:

[0059] S1. Lift the prefabricated column 100 to the designed position, then fix the sleeve 110 on the longitudinal reinforcement of the prefabricated column 100 , and inject grout into the sleeve 110 . The prefabricated columns 100 are arranged vertically, and the sleeves 110 are arranged on the longitudinal steel bars, so as to facilitate docking with the longitudinal steel bars of the upper precast column 100 . Using the sleeve 110 to connect the longitudinal steel bars of the prefabricated components is a prior art, which will not be repeated here.

[0060] S2. Lift the prefabricated beam 200 to the top of the prefabricated columns 100 on both sides, and adjust the elevation of the prefabricated beam 200 to the design position.

[0061] S3. Set up the formwork and pour the joints betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com